Hydraulic control device and control method thereof

A control device and hydraulic technology, applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve the problems of complex technology, complex debugging, increased cost, etc., to prevent position overshoot, excellent performance, high precision The effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

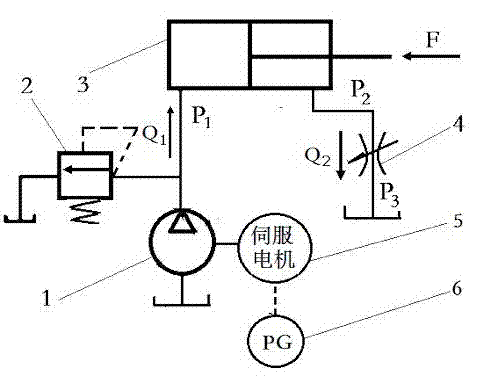

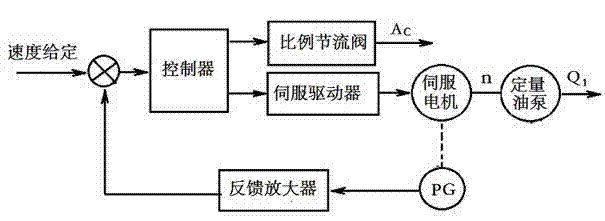

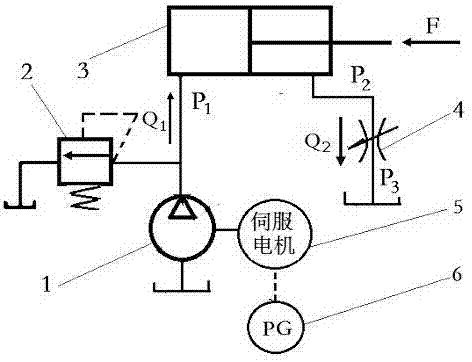

[0021] The principle of the hydraulic control device in the embodiment of the present invention is as follows: figure 1 As shown, it includes a quantitative oil pump 1 and an oil cylinder 3. The outlet of the quantitative oil pump 1 is connected to the oil inlet circuit of the oil cylinder 3, and the oil return circuit of the oil cylinder 3 is connected to the oil tank. The overflow valve 2 of the oil tank 3 is connected in series with a proportional throttle valve 4 as an adjustable liquid resistance on the oil return road of the oil cylinder 3, and the quantitative oil pump 1 is connected with the servo motor 5 that drives it to work.

[0022] In this embodiment, the proportional throttle valve 4 is a servo throttle valve. The aforementioned servo motor 5 is connected to a speed sensor device PG.

[0023] The relationship between the flow rate and pressure of the 3 return oil circuits of the above oil cylinder is as follows:

[0024] Q 1 = nq (1.1)

[0025] Q 2 = Q 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com