Sliding slewing bearing

A slewing bearing and turntable technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of complex manufacturing process of rolling slewing bearing devices, poor impact resistance and vibration resistance, raceway fatigue pitting, etc. Achieve the effect of self-lubricating performance, high load-carrying performance, anti-overturning moment, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

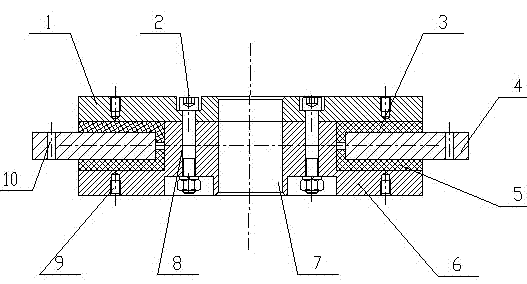

[0016] Embodiment one: if figure 1 The sliding slewing ring shown is suitable for heavy duty conditions. Its structure mainly consists of an upper turntable 1, connecting bolts 2, an upper wear-resistant lubricating ring 3, a turntable 4, a lower wear-resistant lubricating ring 5, and a lower convex turntable 6. The lower convex turntable 6 and the upper turntable 1 are made of metal, the upper turntable 1 is set on the lower turntable 6, the chassis of the lower turntable 6 is a disc, and the middle part of the upper turntable 1 and the lower turntable 6 has a central through hole 7. There are 3 to 6 bolt connection through holes 8 evenly distributed around the central through hole 7, and the bolt connection through holes 8 are equipped with connecting bolts 2, through which the upper turntable 1 and the lower convex turntable 6 are fixed together, After being connected, the upper turntable 1 and the lower convex turntable 6 constitute an inner turntable. A plurality of thr...

Embodiment 2

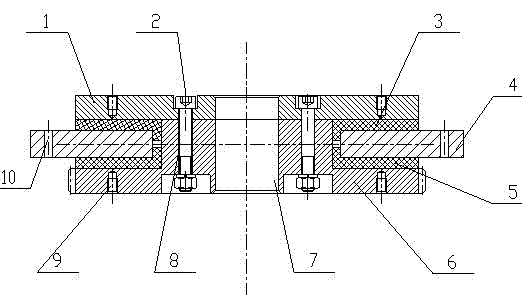

[0017] Embodiment two, such as figure 2 The structure of the sliding slewing bearing shown is basically the same as that of Embodiment 1, and is suitable for heavy-duty working conditions. The difference is that the chassis of the lower convex turntable 6 is a toothed disc, which is connected with the driving device through the toothed disc to form a gear transmission. The same part is omitted. When in use, the sliding slewing bearing is fixed by using the installation through hole 10 on the turntable 4, and the upper turntable 1 and the lower convex turntable 6 are respectively connected to the turning parts and the driving device. When the driving device rotates, it drives the lower convex turntable 6 and the upper turntable 1 to rotate, so that the rotary parts rotate.

Embodiment 3

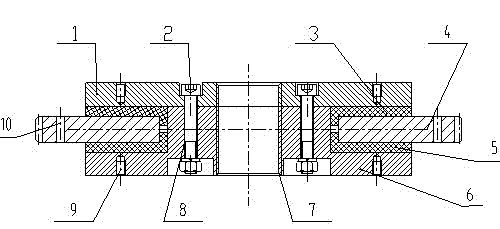

[0018] Embodiment three: as image 3 The structure of the sliding slewing bearing shown is basically the same as that of Embodiment 1, and is suitable for heavy-duty working conditions. The difference is that the turntable 4 is a toothed disc, which is connected with the driving device through the toothed disc to form a gear transmission. The same part is omitted. During use, utilize the threaded blind hole 9 on the upper turntable 1 and the lower convex turntable 6 to fix the sliding slewing bearing, and fix the rotating part on the turntable 4 through the installation through hole 10 on the turntable 4, and the turntable 4 is connected with the driving device. When the driving device rotates, it drives the turntable 4 to rotate, so that the rotary parts rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com