Straw gas heat source engine

A heat source machine and gas technology, applied in the manufacture of combustible gas, heating methods, household heating, etc., can solve the problems of low heating efficiency and waste of energy, and achieve the effect of stable placement, high-efficiency heat source, and increased technological content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

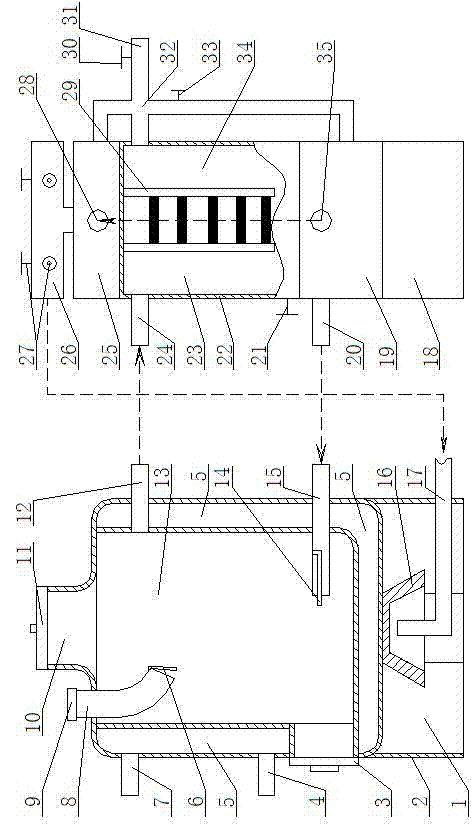

[0023] according to figure 1 The present invention is described in detail.

[0024] The straw gas heat source machine is mainly composed of a gas generator and a gas separator. in:

[0025] The furnace body of the gas generator is respectively provided with two furnaces, i.e. the upper and lower furnaces 13 and 1. The size of the gas generator can be designed according to the amount of heat generated. Generally, the height is 750mm, the diameter is 470mm, and the size of the feeding port is 250mm*150mm. The furnace wall and furnace bottom of the upper hearth are double-layer water injection chambers 5, and the water channels are separated by about two centimeters. The top of the upper furnace 13 is provided with a feeding port 10, and a lock groove sealing furnace cover 11 is provided on the feeding port 10, and a charging port 8 is provided on the furnace shoulder, and a screw cover 9 is provided on the outside, and a valve is provided inside to prevent the leakage of smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com