Monitoring system and method of heat supply network

A monitoring system and heating network technology, which is applied in heating systems, heating methods, household heating, etc., can solve problems such as the inability to effectively adjust heat energy distribution, and achieve the effect of ensuring maximum utilization, normal pressure, and maintaining flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

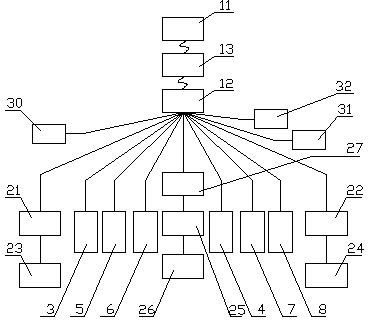

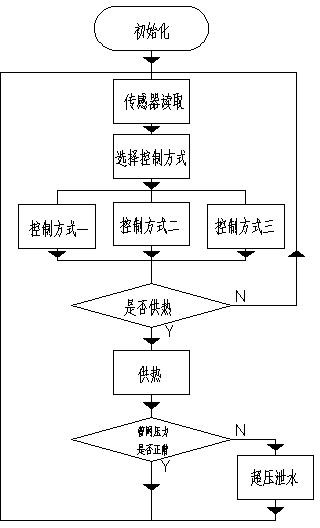

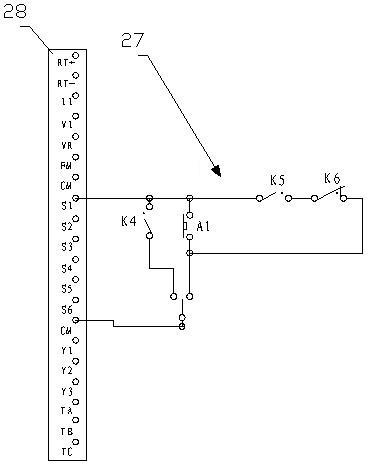

[0029] A heating network monitoring system (refer to attached figure 1 ), this embodiment performs energy-saving control on the heating network. The heating network includes the heating network supervisor, the primary side pipe network supplied by the heat source and multiple secondary side pipe networks directly facing customers. The heat source enters the heating network supervisor, and the heating network supervisor It is connected to the water supply end and return water end of the primary side pipe network, and heat exchange is performed between the primary side pipe network and the secondary side pipe network through a heat exchanger. The secondary side circulation pump 22 of the heating network is arranged on the side pipe network, and the heating network also includes a water supply tank, which can supply water to the secondary side pipe network through the water supply pump 26. In this embodiment, a sub-monitoring system and a host computer 11 Composition, including t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com