Optical fiber grating microbend sensor based on cladding mode transmission

A microbend sensor and fiber grating technology, which is applied in the direction of using optical devices to transmit sensing components, instruments, and optical devices, etc., can solve the problems of increasing the difficulty of multiplexing wavelength demodulation, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

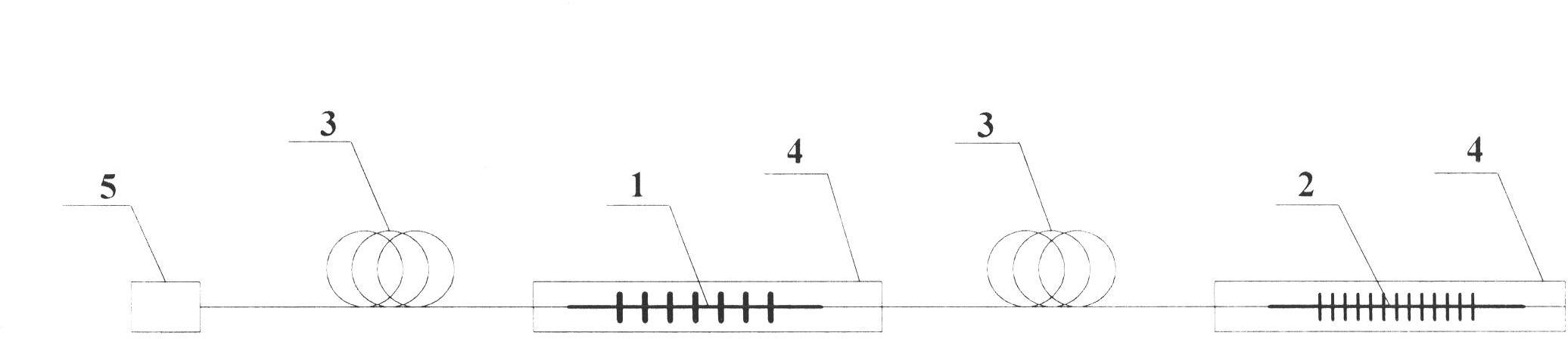

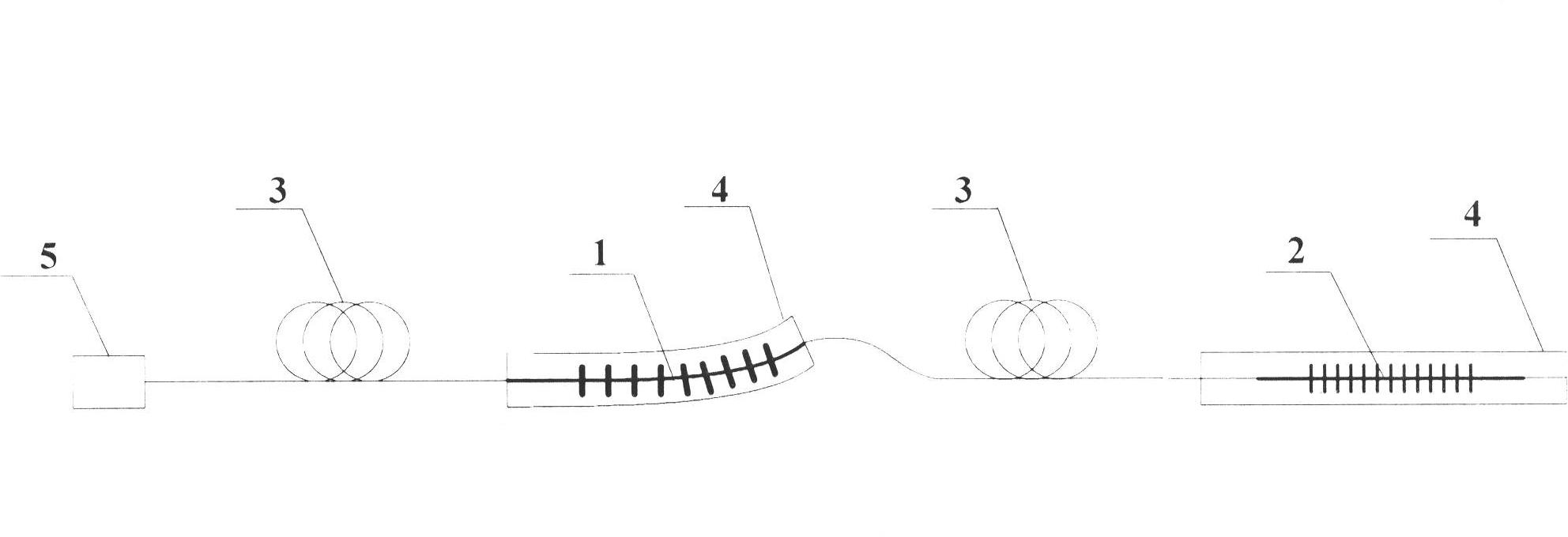

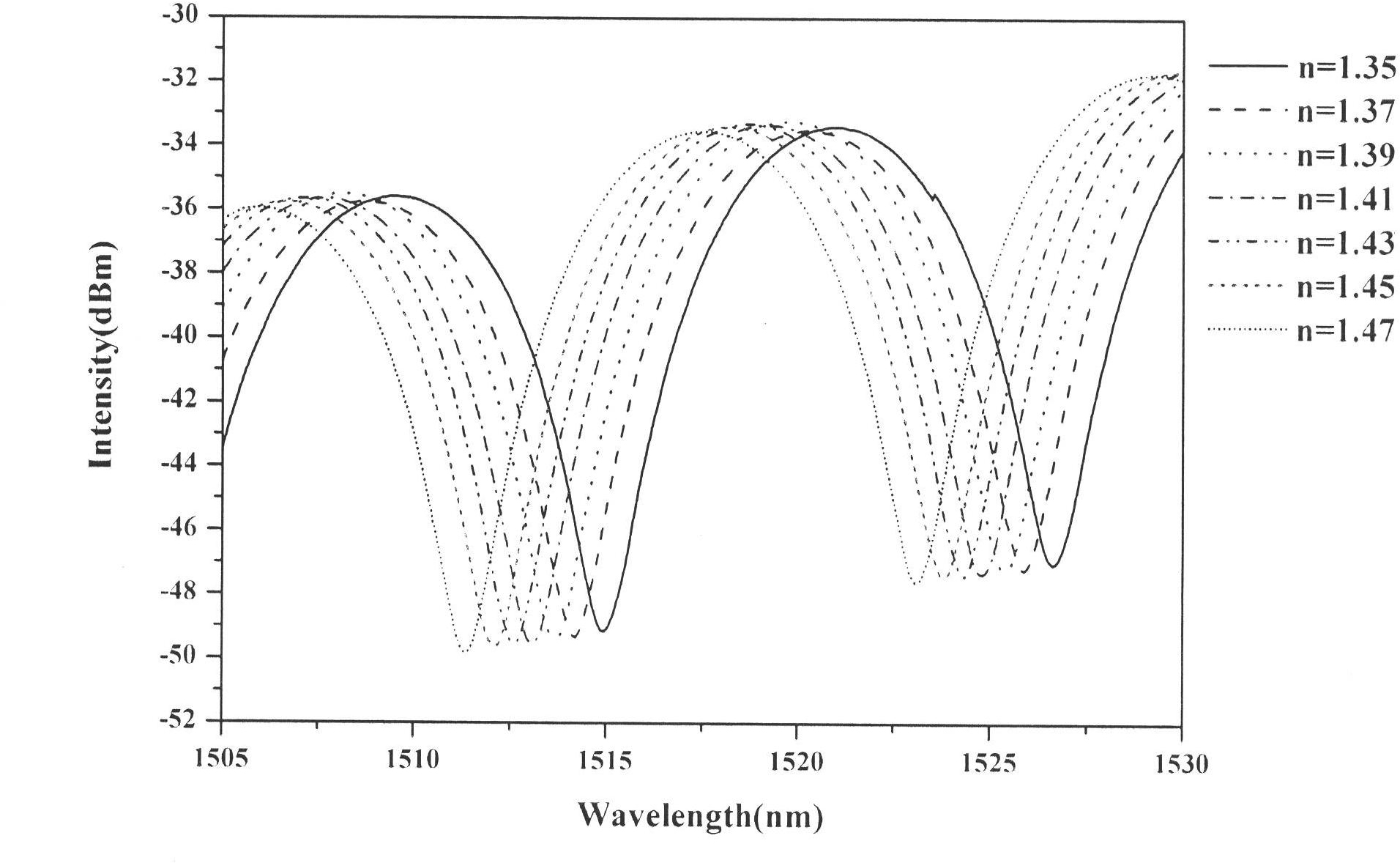

[0020] See attached figure 1 , a fiber Bragg grating microbend sensor based on cladding mode transmission, which is constructed as follows: a long-period fiber grating (1), a fiber Bragg grating (2), a single-mode fiber (3), a packaging sleeve (4) and a connecting The head (5) is composed. The long-period fiber grating (1) is connected to the connector (5) through a single-mode fiber (3) before, and the long-period fiber grating (1) is connected to the fiber Bragg grating (2) through a single-mode fiber (3) afterwards, and the long-period fiber Both the grating (1) and the fiber Bragg grating (2) are protected by a packaging sleeve (4). When light is transmitted through the LPFG (1) in the single-mode fiber (3), part of the core mode is coupled into the cladding of the LPFG (1), and the cladding mode and the rest of the core mode continue along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com