Passive sensor and sensing method thereof

A passive sensor and sensor technology, which is applied in the sensor field to achieve the effects of simple structure, convenient use and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

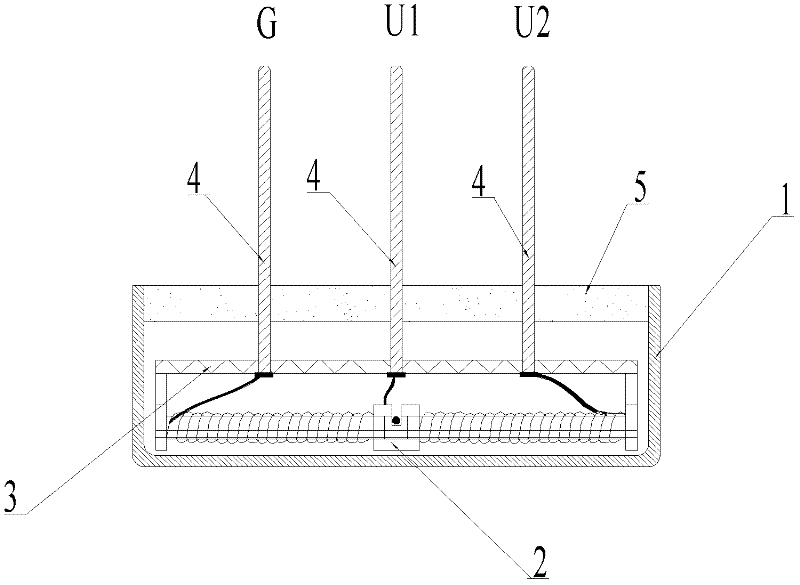

[0025] Such as figure 1 , figure 2 As shown, the dual-function passive sensor of the present invention includes a casing 1, and a sensitive component 2 is housed in the casing 1, and the sensitive component 2 is electrically connected to three outer leads 4 through a printed board 3, and the port of the casing 1 is encapsulated with an epoxy resin sealing material 5 .

[0026] Wherein, the shell 1 is an aluminum cylindrical shell with a diameter of φ11 mm and a height of 6 mm; the size of the printed board 3 is adapted to the inner diameter of the shell, and mainly serves as a transitional circuit between the sensitive component 2 and the outer lead 4. Connection as; the outer lead 4 includes 1 ground wire G, 2 output wires U 1 and U 2 , The spacing of the 3 leads conforms to the standard spacing of single in-line devices, which is convenient for installation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com