LED (light-emitting diode) display screen constant-current driving circuit with optional mirror image ratio

An LED display, constant current drive technology, applied in static indicators, instruments, etc., can solve the problems that affect the display quality of full-color LED display, increase the power supply voltage, difficult to build, etc., to improve the driving current and constant current. Accuracy, improved performance, improved display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

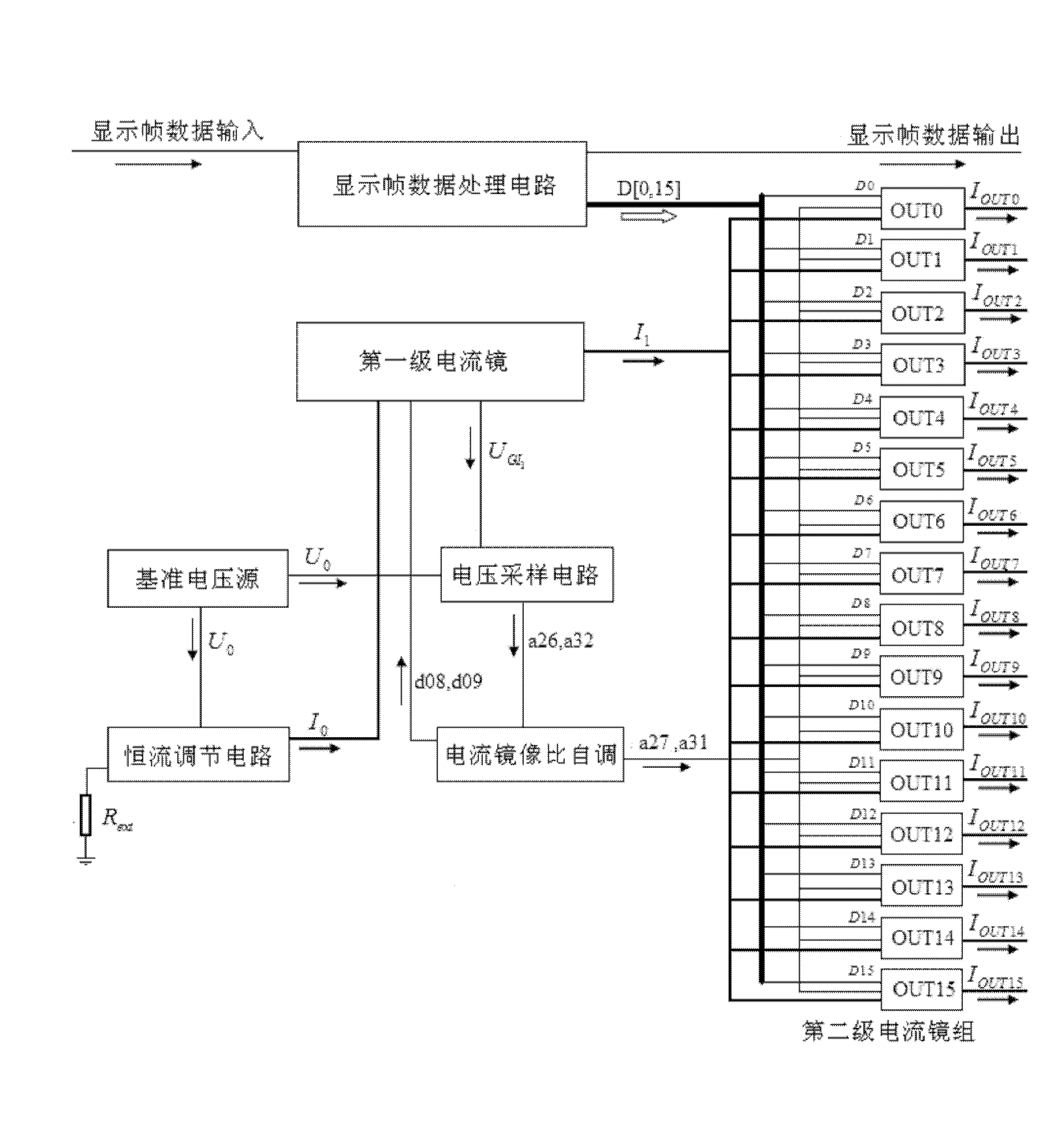

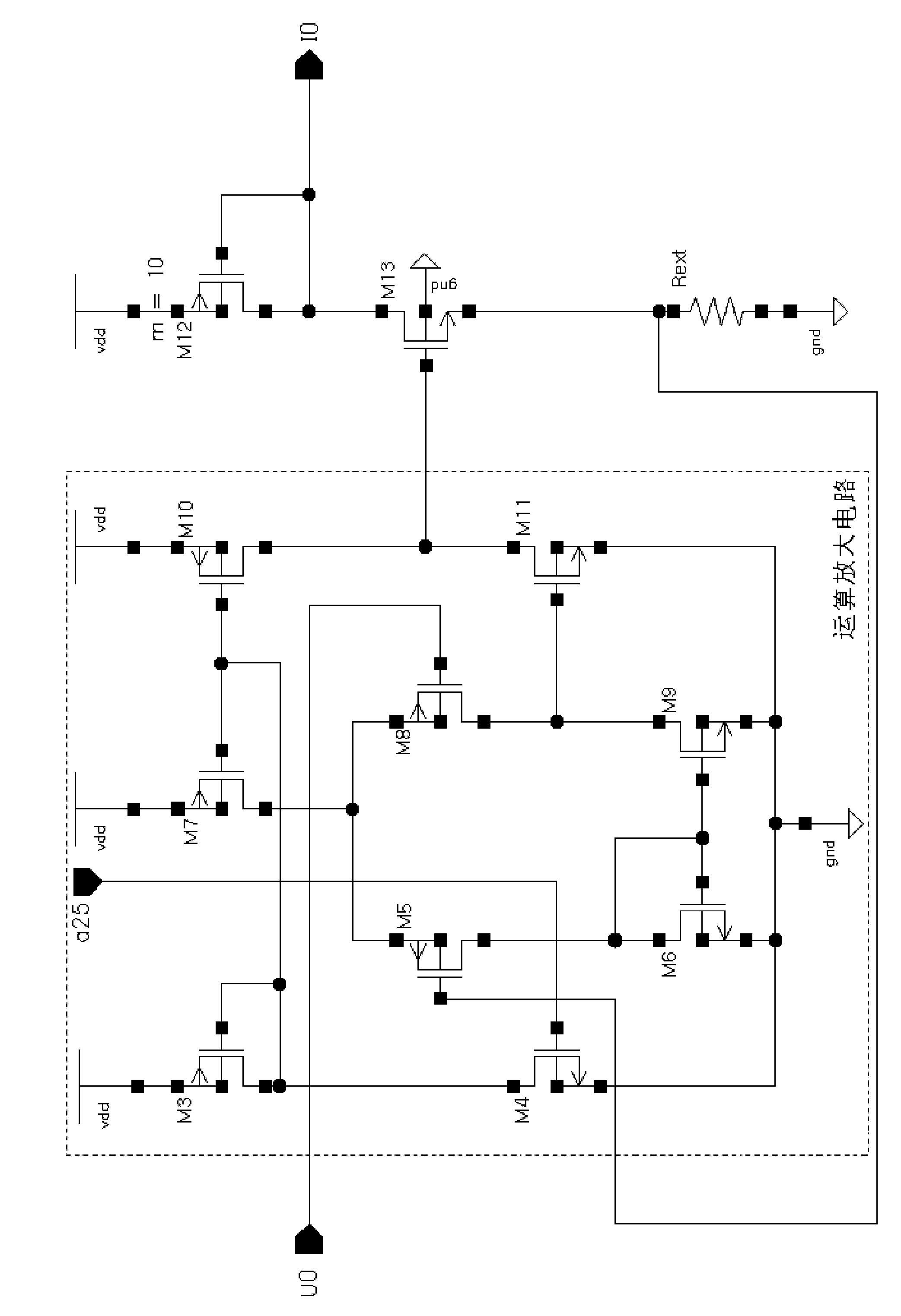

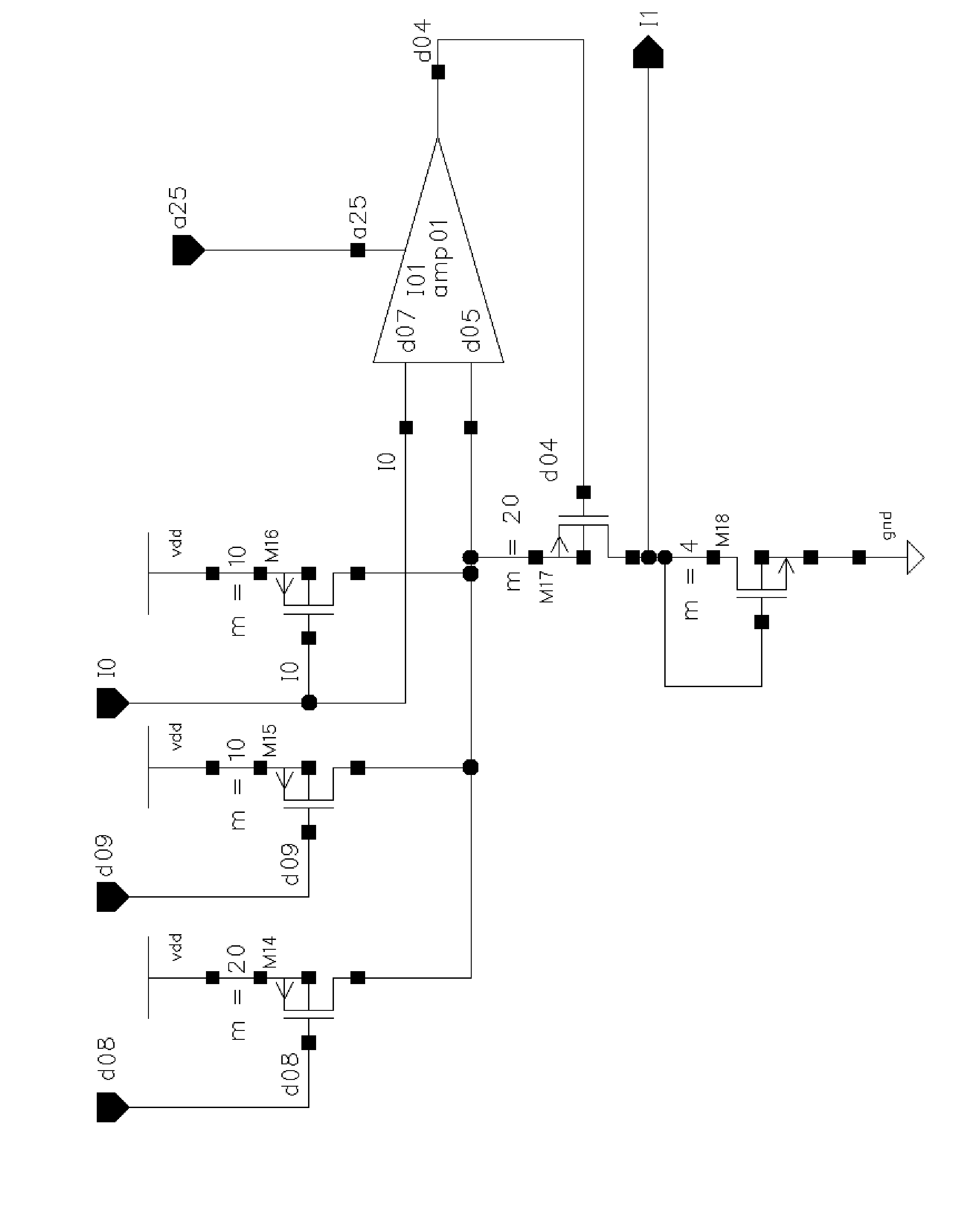

[0028] see Figure 1 to Figure 6 , LED display constant current drive circuit with optional mirror ratio, including reference voltage source circuit, constant current regulation circuit, voltage sampling circuit, current mirror ratio self-adjusting circuit, first-stage current mirror with adjustable mirror ratio, adjustable mirror ratio The second-stage current mirror group and the display frame data processing circuit; the reference voltage source circuit is respectively connected with the constant current regulation circuit and the voltage sampling circuit for generating the reference voltage U 0 , and set the reference voltage U 0 input to the constant current regulation circuit and the voltage sampling circuit respectively; the constant current regulation circuit is connected with the first-stage current mirror, and is used to generate the reference voltage U according to the reference voltage source circuit 0 , generating a constant current I 0 , and the constant curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com