Intelligent dimming high-efficiency and constant-current LED drive chip

A technology of LED driving and intelligent dimming, which is applied in the field of lighting, and can solve problems such as inability to adjust light, small dimming range, and incompatible operation of power drivers and dimmers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

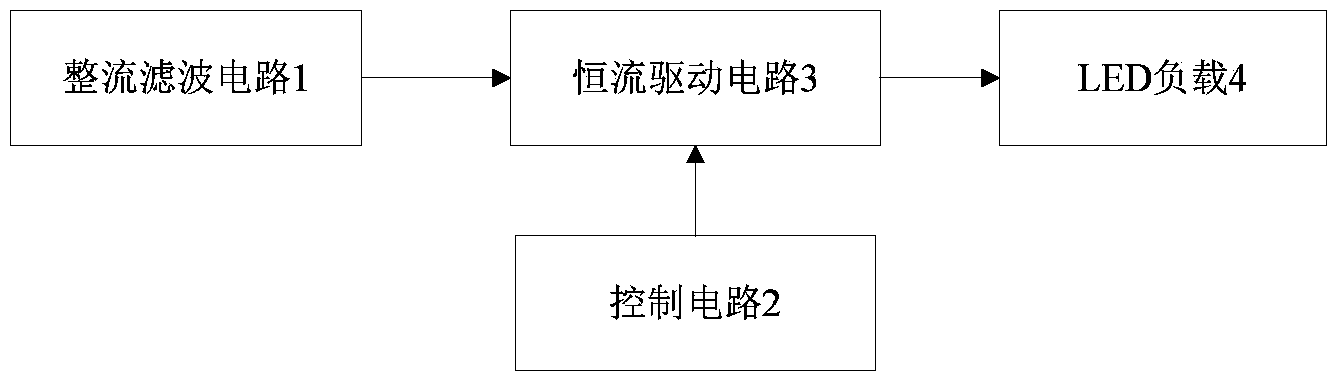

[0017] as attached figure 1 As shown, a schematic block diagram of the principle of an intelligent dimming high-efficiency constant current LED driver chip, EMI filter circuit 1, control circuit 2, chopper circuit 3, flyback conversion circuit 4 and LED load 5, the EMI filter circuit 1 , the chopper circuit 3 , the flyback conversion circuit 4 and the LED load 5 are sequentially connected, and the control circuit 2 is connected to the chopper circuit 3 and the flyback conversion circuit 4 .

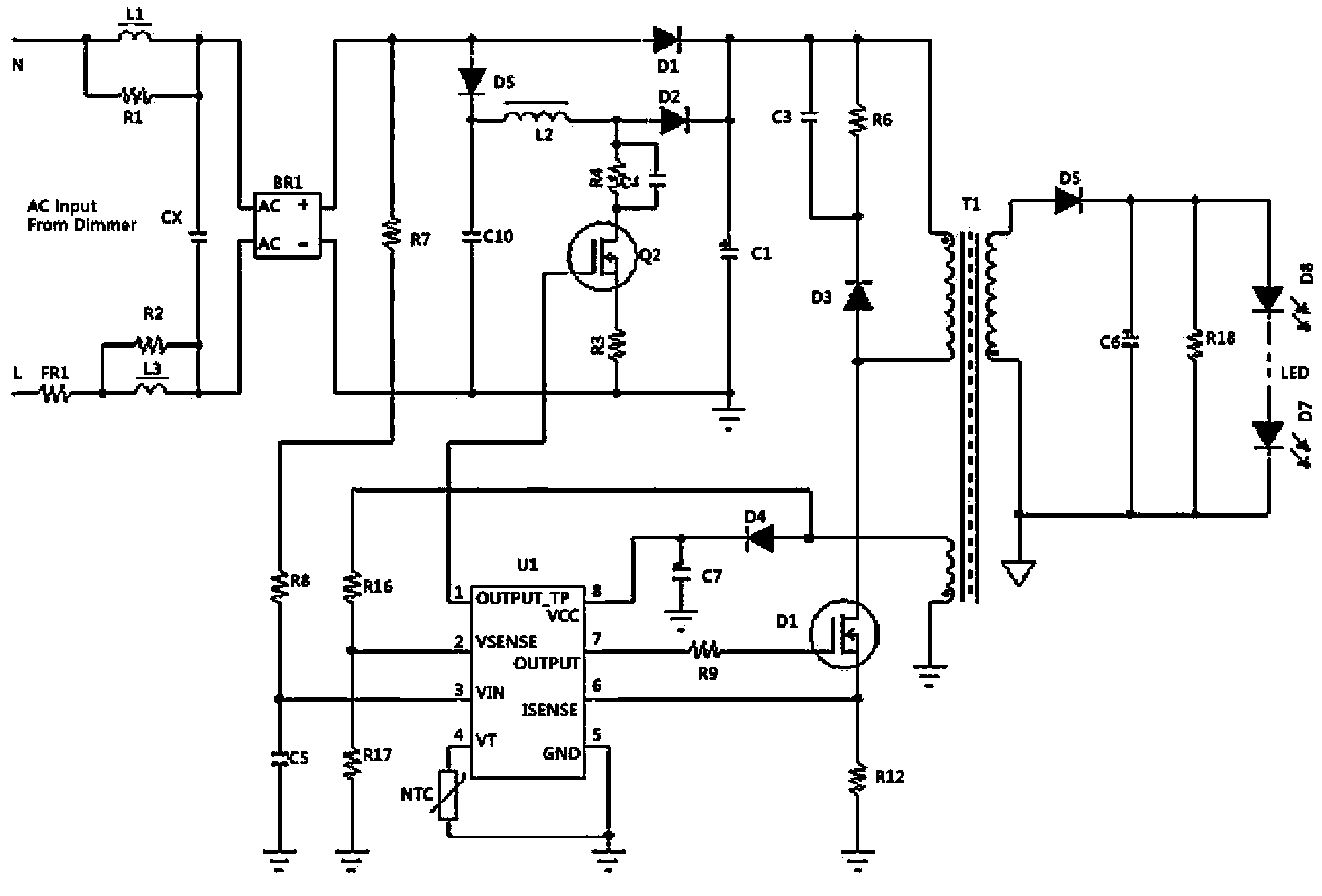

[0018] as attached figure 2 As shown, a circuit design schematic diagram of an intelligent dimming high-efficiency constant current LED driver chip. The control circuit 2 includes a highly integrated high power factor constant current drive LED chip U1, the chip model is iW3610, and the chip pins include OUTPUT_TR, Vsense, VIN, VT, GND, Isense, OUTPUT and VCC; the control circuit 2 It also includes resistors R7, R8, R16, R17, R5, R12, thermistor NTC and MOSFET tube Q1. Resistors R7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com