Roller holder for a line guide segment of a strand casting machine

A technology of continuous casting slab and continuous casting machine, which is applied in the field of roll frame of the continuous casting slab guiding sector of the continuous casting machine, and can solve the problems of small roll distance, small space, high maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

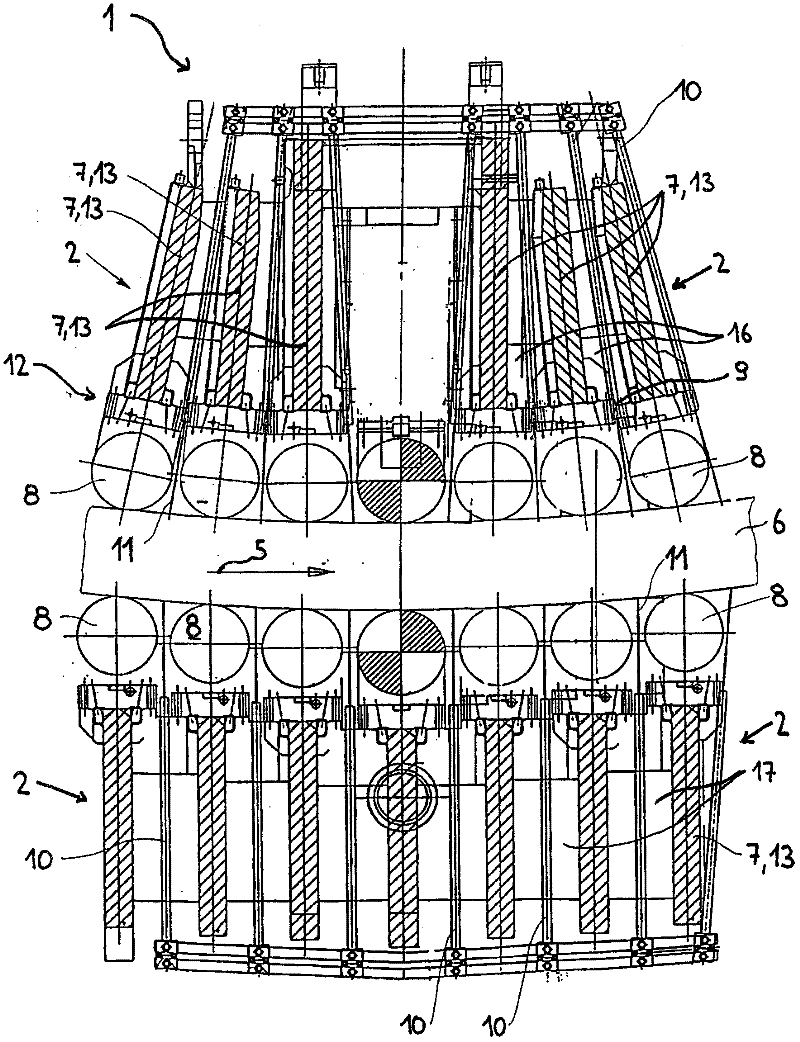

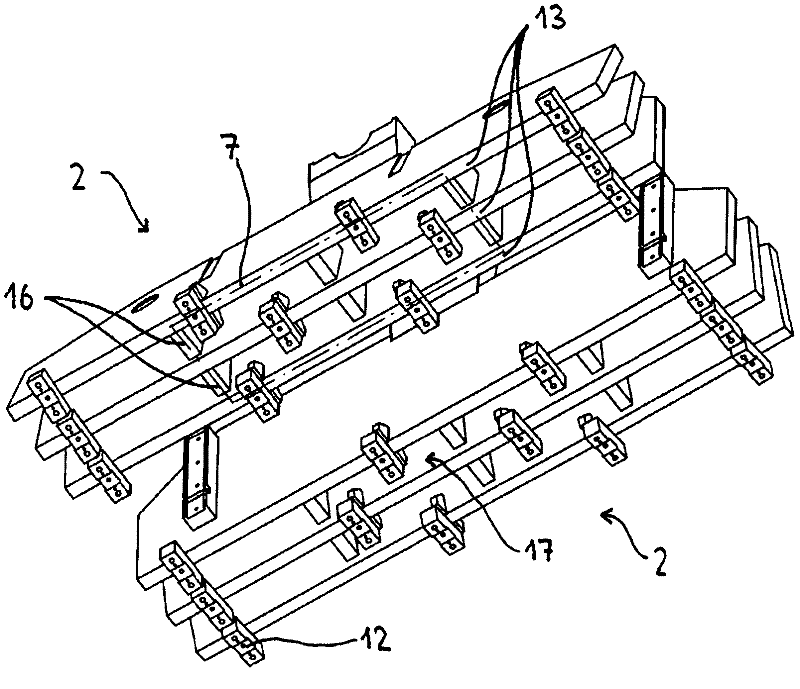

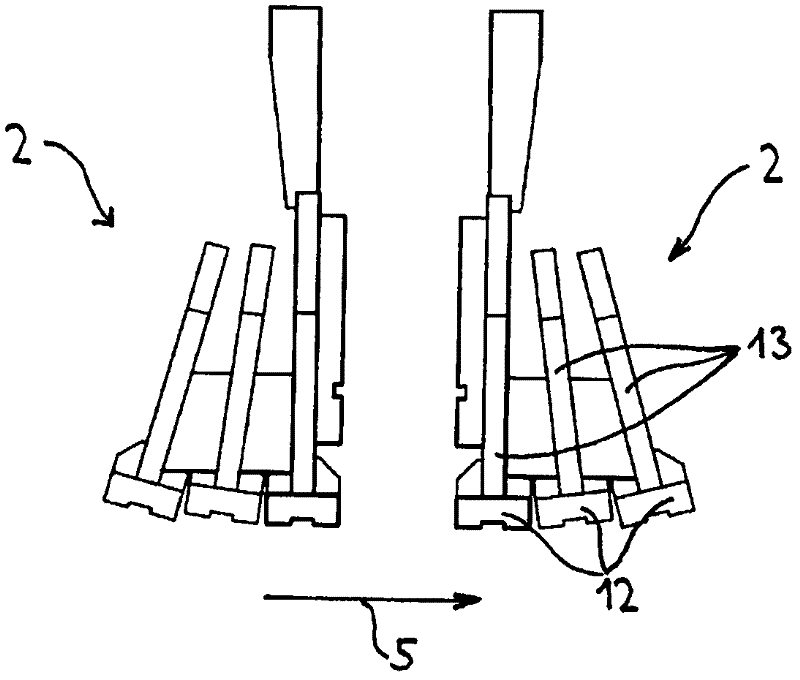

[0048] figure 1 A slab guide segment 1 of an arc-shaped continuous casting plant is shown in section, which has a figure 1 ) of the roll stand 2. As usual in continuous casting, liquid steel is cast in a mold (not shown), wherein the liquid steel is cooled and forms an at least partially solidified strand in the mold. Subsequently, the slab is pulled out of the mold, the slab is supported in a slab support device comprising a plurality of slab guide segments 1 behind the mould, and in the slab support Guided and further cooled in the unit. In the strand guide segment 1 , the strand in the form of a slab 6 is supported by a plurality of strand guide rollers 8 on each of a roll stand 2 . Each roll stand 2 has a rectangular closed frame 7 consisting of three transverse beams 13 arranged transversely to the casting direction 5 and of six longitudinal plates 16 arranged in the casting direction 5 , wherein the frame 7 is formed by means of The beams 13 and the longitudinal plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com