Automatic tube insertion chain of plastic bottle tube heater

A heater and plastic bottle technology, applied in the field of plastic machinery, can solve the problems of high power consumption, high production cost, unstable operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

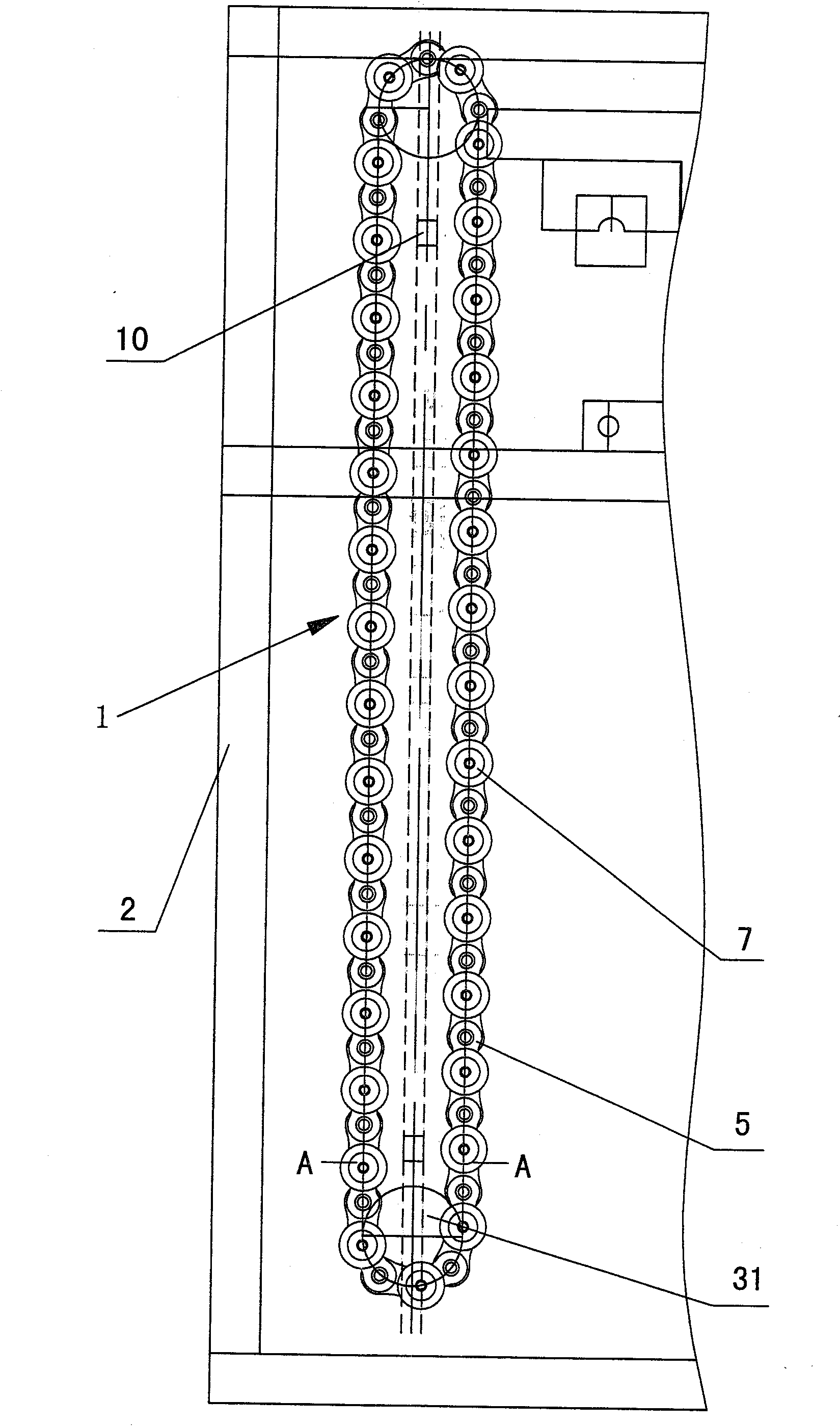

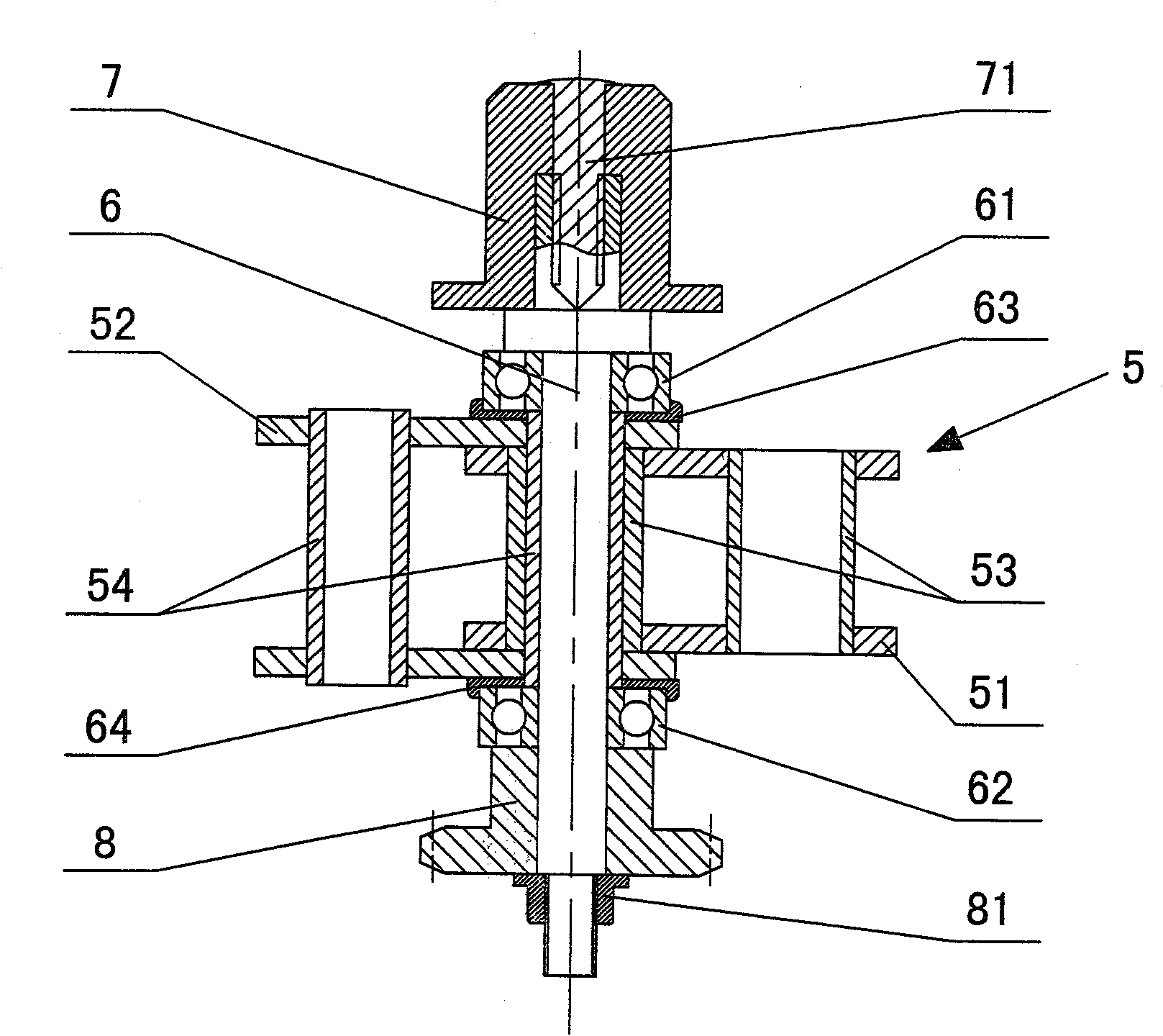

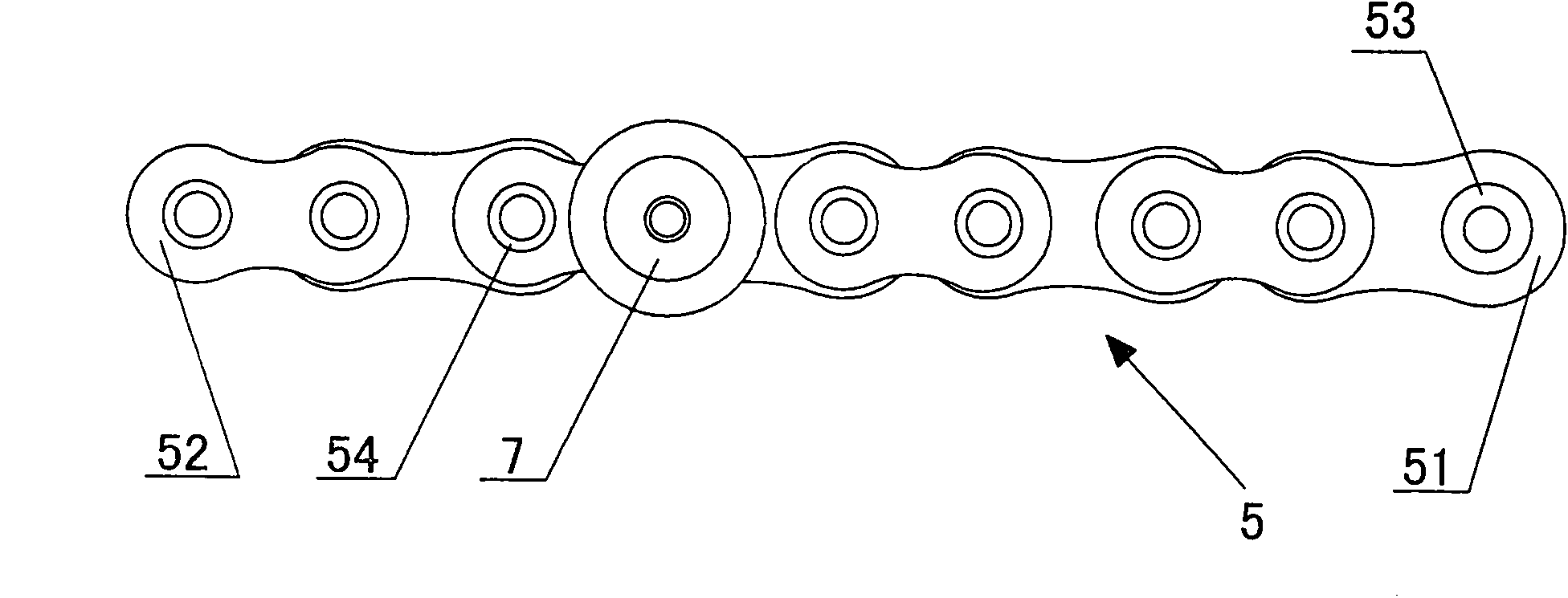

[0015] like Figure 1-Figure 6 As shown, the intubation chain of the plastic bottle tube heater itself includes a frame 2, and a bottle tube conveying mechanism 1 is installed on the frame. Drive the driven sprocket through the conveying chain 5, and the conveying chain 5 drives the bottle tube support seat. The conveying chain 5 includes an inner chain piece 51 and an outer chain piece 52, and the inner chain piece 51 and the outer chain piece are connected by chain pins. The chain pins described include long pipe chain pins 54 and short pipe chain pins 53. The two ends of the long pipe chain pins 54 are respectively fixed with the outer chain sheet 52. The short pipe chain pins 53 are sleeved outside the long pipe chain pins 54. The inner chain piece 51 is fixed, and it is characterized in that the bottle tube support shaft 6 is installed inside the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com