Metal sand damper

A technology of dampers, metal sand, applied in the direction of building components, shockproof, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

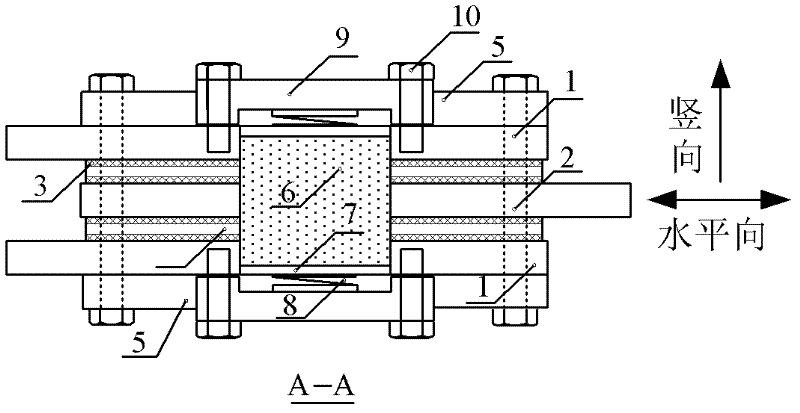

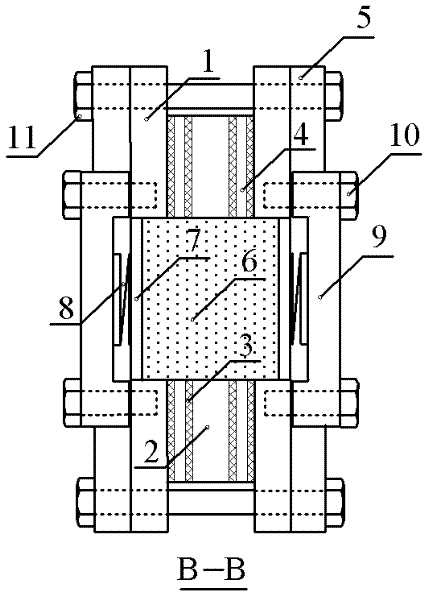

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

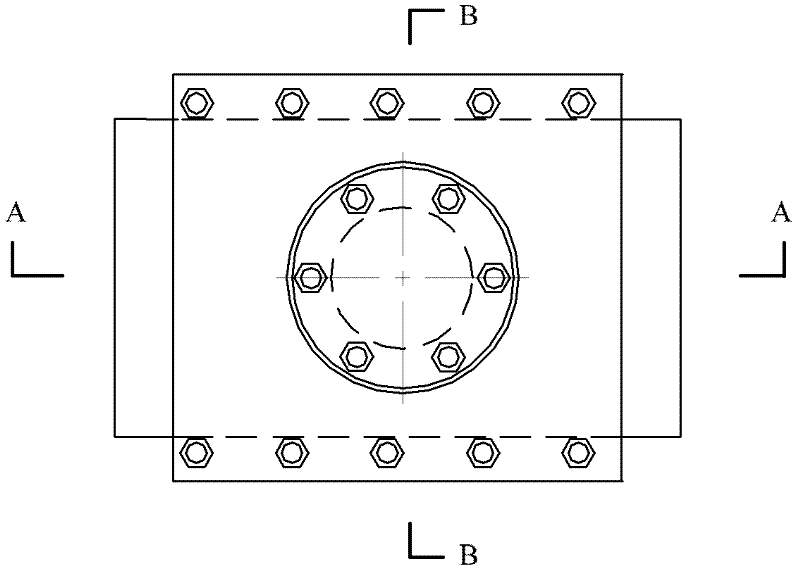

[0013] Depend on Figure 1 ~ Figure 3 As shown, the damper in the embodiment includes: a first steel plate 1, a second steel plate 2, a rubber sheet 3, a steel partition 4, a splint 5, metal sand 6, a backing plate 7, a disc spring 8, a cover plate 9, Bolt 10, Bolt 11.

[0014] The second steel plate 2 is placed between two steel separators 4, and together they are placed between two first steel plates 1, and the adjacent steel plates are bonded together by vulcanization with rubber sheets 3 and adhesives. , to form a composite part 1; a hole is opened in the middle part of the composite part 1; a backing plate 7, a disc spring 8 and a cover plate 9 are installed in sequence at one end of the hole and initially fixed with bolts 10; the iron sand 6 is poured from the other end Install backing plate 7, disc spring 8, and cover plate 9 in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com