Air inlet pipe with cyclone cylinder structure

A swirl tube and intake pipe technology, which is applied in the directions of fuel air filter, combustion air/combustion-air treatment, engine components, etc., can solve the problem of long service life, coarse filter effect can not meet the requirements of floating land use, and filter element burden. Heavy and other problems, to achieve the effect of low cost, simple structure and low system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

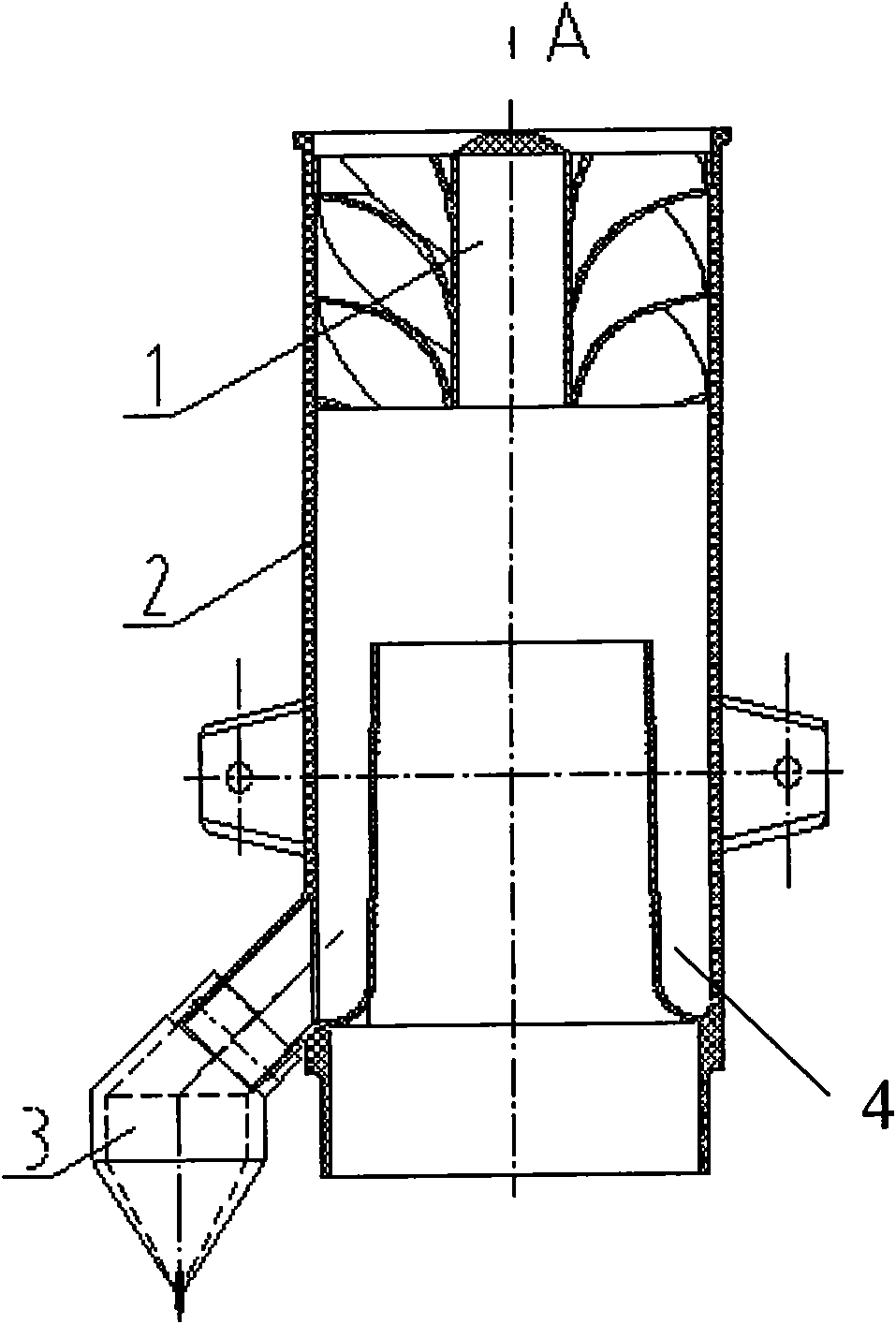

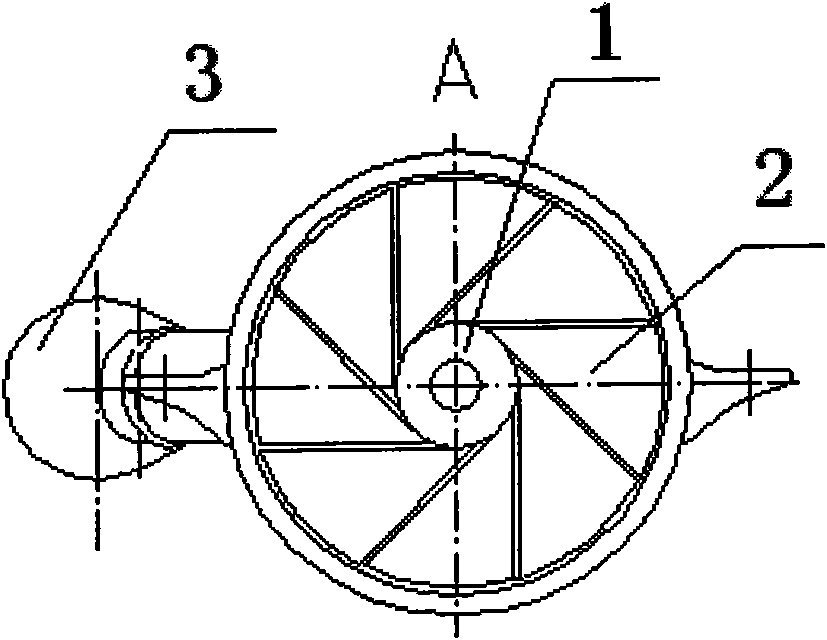

[0015] Such as figure 1 with figure 2 As shown, the present invention is adopted in the intake pipeline of Jiefang light-duty vehicles, wherein the swirl vane adopts the structure of 8 blades, and the design scheme can also adopt 3 schemes consisting of 6, 8, and 10 blades. After testing and verification, 8 blades The separation of the leaves is the best.

[0016] working principle:

[0017] 1. Negative pressure is generated when the engine takes in air, and a large amount of air is sucked in. The intake air flow enters the pre-filter device, and when it passes through the swirl plate 1, it will generate high-speed rotating motion, and the particles with larger mass will be separated under the action of centrifugal force.

[0018] 2. The lower part of the cyclone cylinder 2 is provided with a dust collection chamber 4, through the action of the split flow and centrifugation, most of the dust particles in the air fall into the dust collection chamber at the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com