Butane-pushing method and system in pearl wool production

A technology of propulsion system and pearl cotton, which is used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., to save nitrogen usage costs, ensure stable operation, and ensure safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

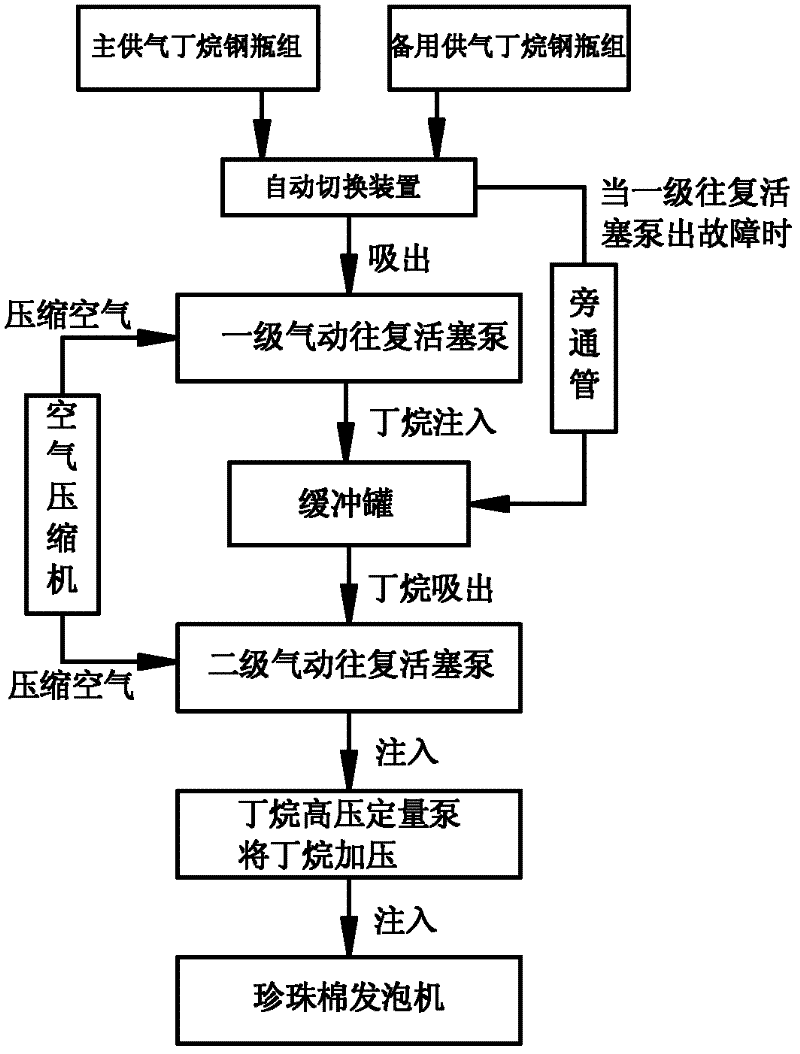

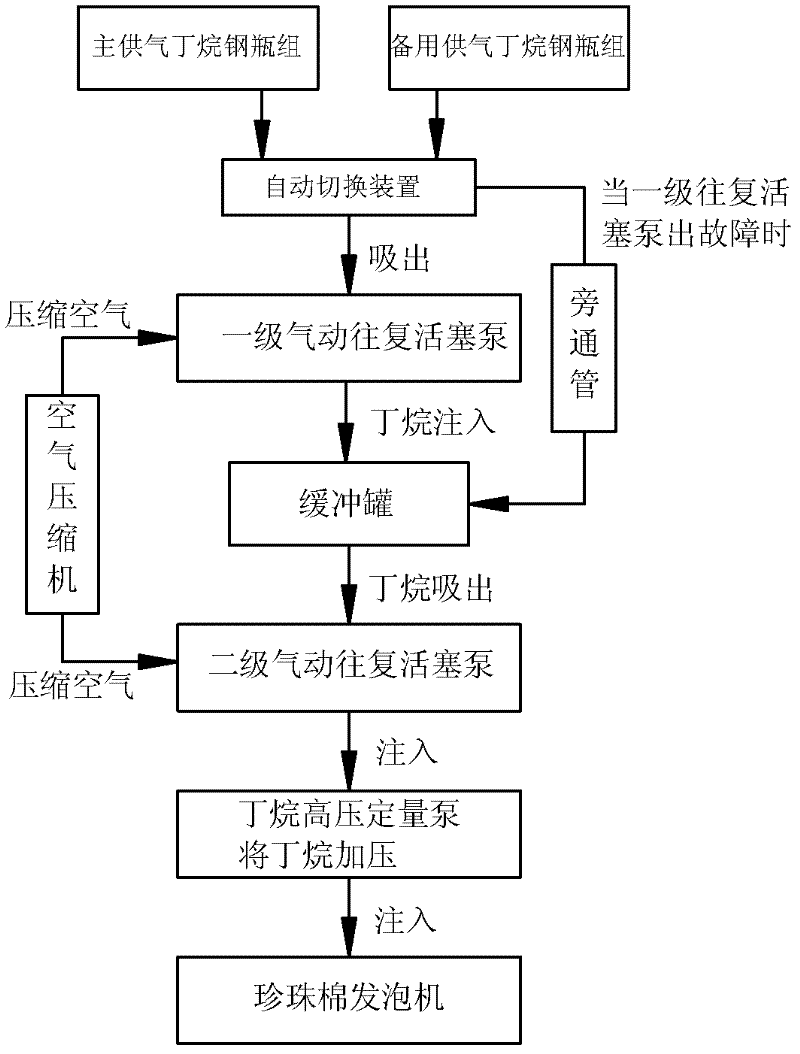

[0031] Embodiment 1 of the present invention: as figure 1 As shown, a butane propulsion method used in the production of pearl cotton uses compressed air to drive a pneumatic reciprocating piston pump, and the pneumatic reciprocating piston pump extracts the butane in the butane cylinder and transports it to the buffer tank. After the butane is pressurized again, it is injected into the pearl cotton foaming equipment to participate in foaming, which specifically includes the following steps:

[0032] Step a: The compressed air generated by the air compressor is delivered to the first-stage pneumatic reciprocating piston pump and the second-stage pneumatic reciprocating piston pump respectively through the air connection pipeline;

[0033] Step b: The butane in the butane steel cylinder is sucked out by the suction generated by the first-stage pneumatic reciprocating piston pump and delivered to the buffer tank;

[0034] Step c: The butane in the buffer tank is pressurized by ...

Embodiment 2

[0039] Embodiment 2 of the present invention: as figure 1 As shown, a butane propulsion method used in the production of pearl cotton uses compressed air to drive a pneumatic reciprocating piston pump, and the pneumatic reciprocating piston pump extracts the butane in the butane cylinder and transports it to the buffer tank. After the butane is pressurized again, it is injected into the pearl cotton foaming equipment to participate in foaming, which specifically includes the following steps:

[0040] Step a: The compressed air generated by the air compressor is delivered to the first-stage pneumatic reciprocating piston pump and the second-stage pneumatic reciprocating piston pump respectively through the air connection pipeline;

[0041] Step b: The butane in the butane steel cylinder is sucked out by the suction generated by the first-stage pneumatic reciprocating piston pump and delivered to the buffer tank;

[0042] Step c: The butane in the buffer tank is pressurized by ...

Embodiment 3

[0047] Embodiment 3 of the present invention: as figure 1 As shown, a butane propulsion method used in the production of pearl cotton uses compressed air to drive a pneumatic reciprocating piston pump, and the pneumatic reciprocating piston pump extracts the butane in the butane cylinder and transports it to the buffer tank. After the butane is pressurized again, it is injected into the pearl cotton foaming equipment to participate in foaming, which specifically includes the following steps:

[0048] Step a: The compressed air generated by the air compressor is delivered to the first-stage pneumatic reciprocating piston pump and the second-stage pneumatic reciprocating piston pump respectively through the air connection pipeline;

[0049] Step b: The butane in the butane steel cylinder is sucked out by the suction generated by the first-stage pneumatic reciprocating piston pump and delivered to the buffer tank;

[0050] Step c: The butane in the buffer tank is pressurized by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com