Drying and curing technology for coil and body of transformer

A transformer coil and solidification process technology, applied in coil manufacturing, etc., can solve problems such as product quality impact, coil insulation aging, power consumption and other resources, reduce production costs and resource energy consumption, ensure insulation thermal performance, and reduce power consumption. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the present invention, the transformer coil and the device body are dried and cured in an electric drying room respectively. After the transformer coil is press-fitted, it is dried and cured in an electric drying room with a power of 30-50kW. The drying and curing temperature is 140°C, and the drying and curing time is 3-3.5 hours. After drying and curing, a fan is used for strong cooling; The high-power electric drying room is used for drying and curing. The drying and curing temperature is 130°C, and the drying and curing time is generally 12 to 15 hours. insulation resistance.

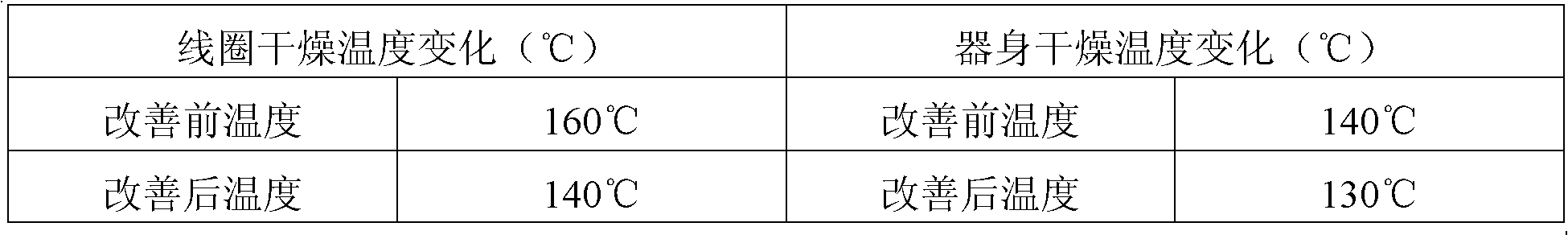

[0012] Table 1. Temperature change of coil and body drying process

[0013]

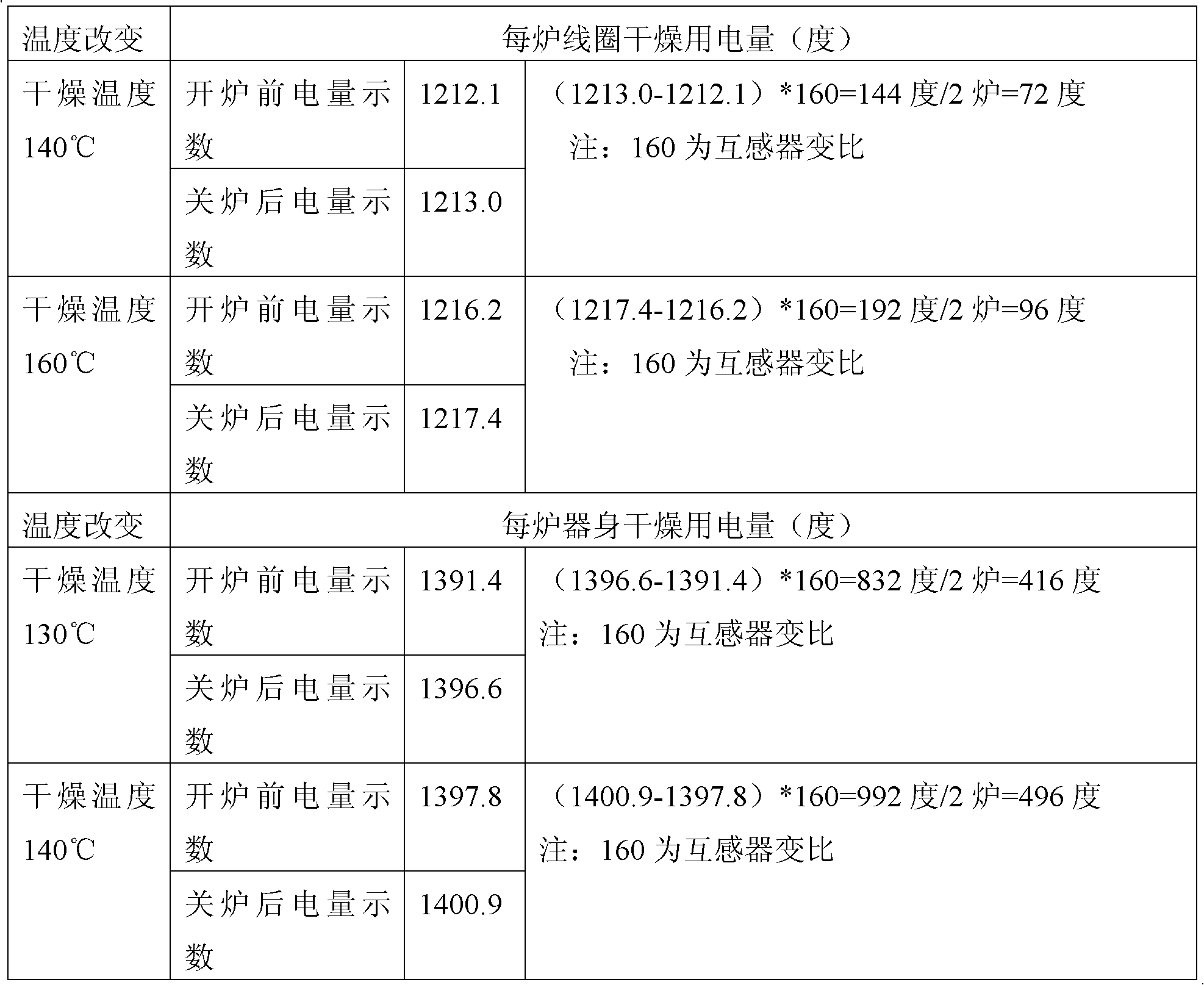

[0014] After closing other electrical equipment, open 2 coil drying ovens and 2 body drying ovens separately to dry according to the original process temperature and the improved process temperature. The specific process parameters and power consumption are shown in Table 2:

[0015] Table 2. Comparison tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com