Surface treatment device and method thereof

A surface treatment device and surface treatment technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting interface coverage and density, unfavorable component manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to enable your review committee to have a further understanding and understanding of the characteristics, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be explained below, so that the review committee can understand the present invention The characteristics are described in detail as follows:

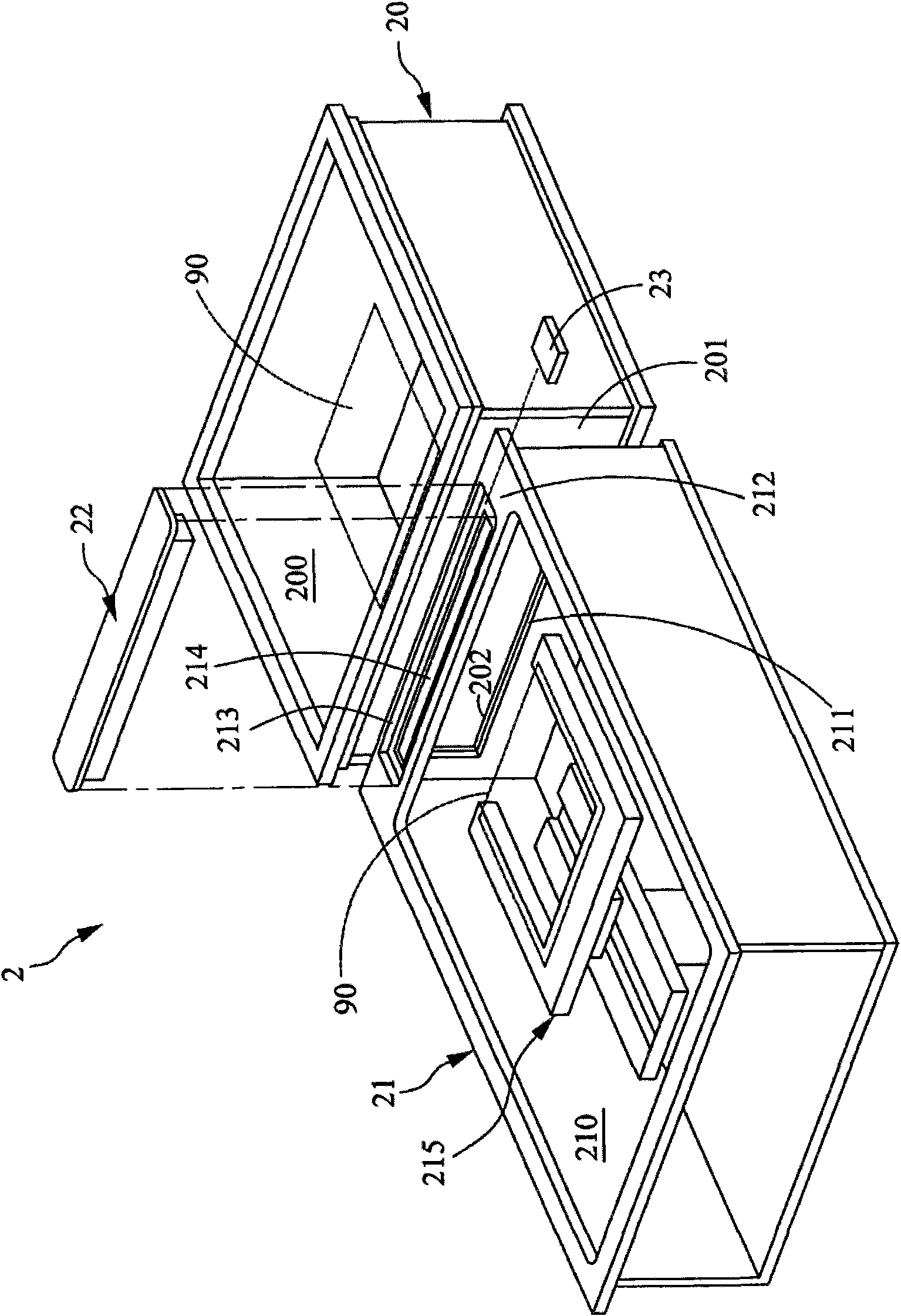

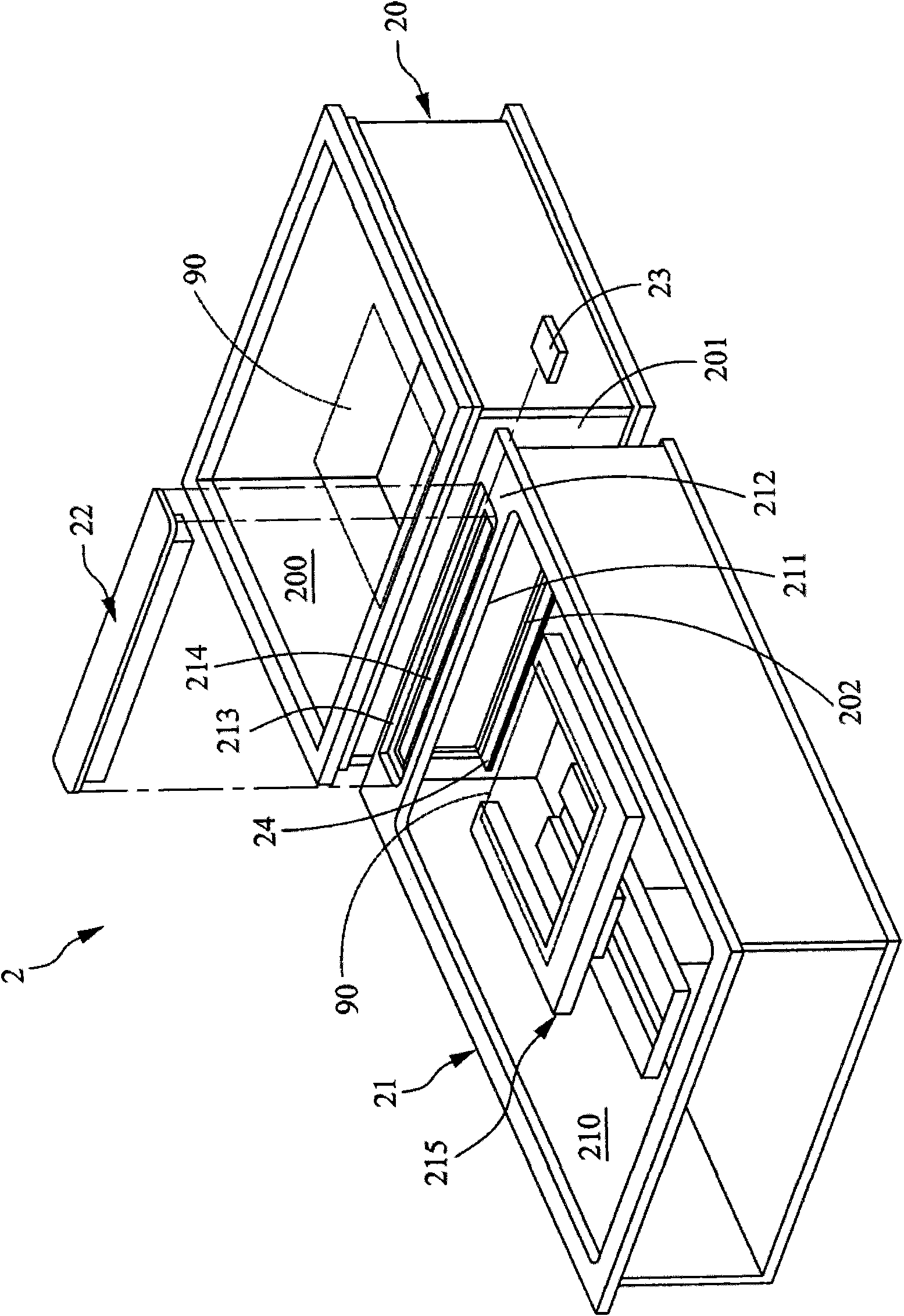

[0071] see Figure 1AAs shown, this figure is a schematic perspective view of an embodiment of the surface treatment device of the present invention. The surface treatment device 2 includes a process chamber 20 , a transmission chamber 21 , a plasma generating device 22 and a control unit 23 . The process chamber 20 has a process space 200 therein to accommodate a substrate 90, and the process chamber 20 can provide a deposition process, so that the substrate 90 in the process chamber 20 is formed as Figure 1B A deposited layer 91 is shown. In this embodiment, the depositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com