Ventilating and radiating system for switch cabinet chamber of semi-buried box-type substation

A box-type substation, ventilation and heat dissipation technology, applied in the cooling/ventilation of substation/switchgear, etc., can solve the problems of increasing uncertain factors, insufficient guarantee of transformer room sealing, difficulty in ensuring safe operation of transformers, etc., to achieve Avoid water ingress, excellent effect, and ensure sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

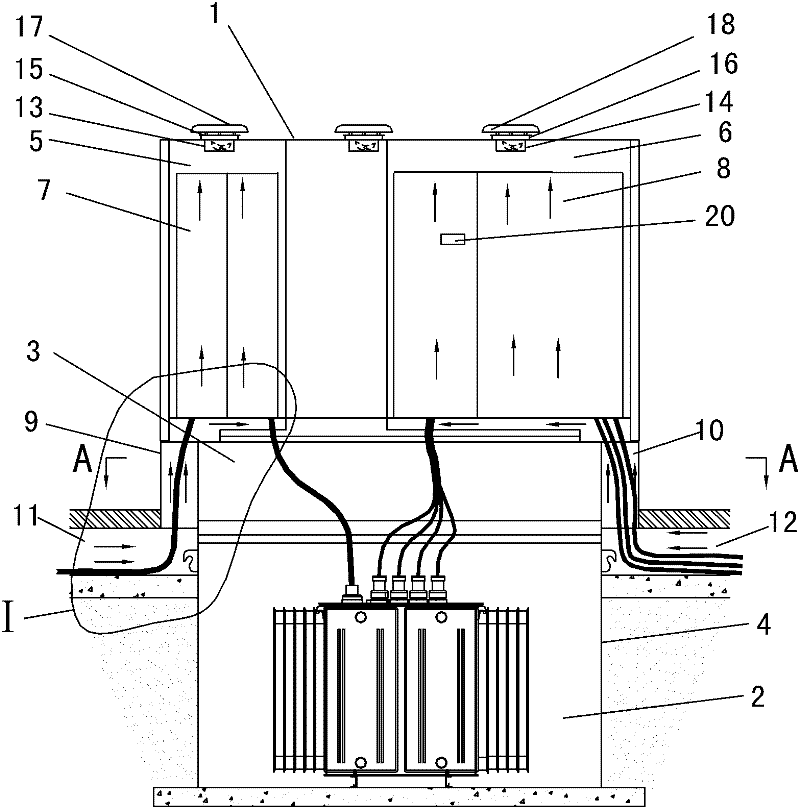

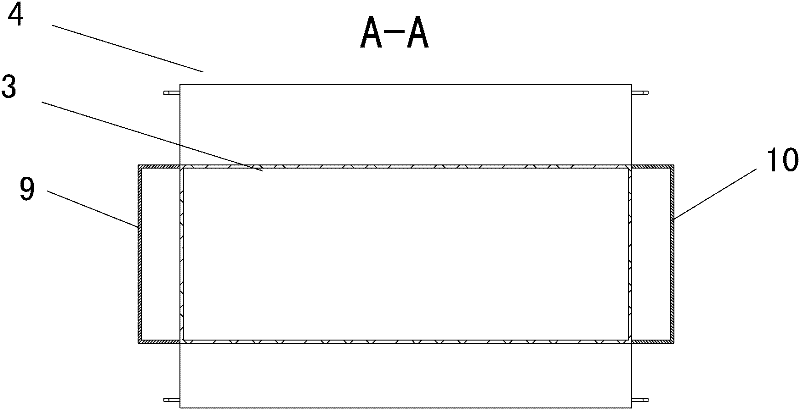

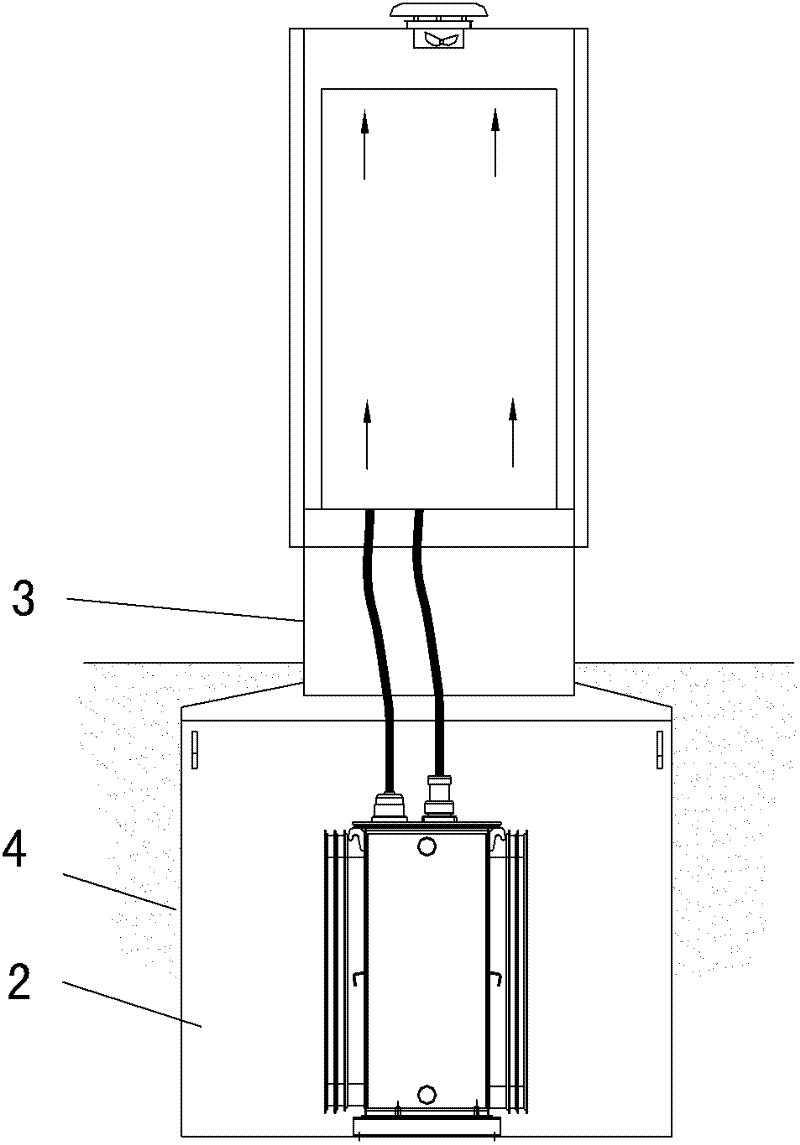

[0022] Such as figure 1 As shown: the semi-buried box-type substation involved in the present invention includes an upper box body 1 and a lower box body 2, most of the lower box body 2 is buried underground, part of its neck 3 is exposed to the ground surface, and the lower part 4 is completely buried below the ground surface . A high-voltage cabinet room 5 and a low-voltage cabinet room 6 are respectively arranged on the left and right sides of the upper box, in which a high-voltage cabinet 7 and a low-voltage cabinet 8 are respectively placed. The surroundings of the high-voltage cabinet room 5 and the low-voltage cabinet room 6 are sealed, and the bottom and top of the high-voltage cabinet 7 and the low-voltage cabinet 8 are connected. The two sides of the neck 3 of the upper box body are respectively installed with the high-voltage cabinet room air inlet duct 9 and the low-voltage cabinet room air inlet duct 10 as the cable inlet and outlet channels, and the lower openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com