Solar automatic tobacco curing room

A technology of flue-cured tobacco room and solar energy, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as emission of pollutants, and achieve the effect of realizing automation and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

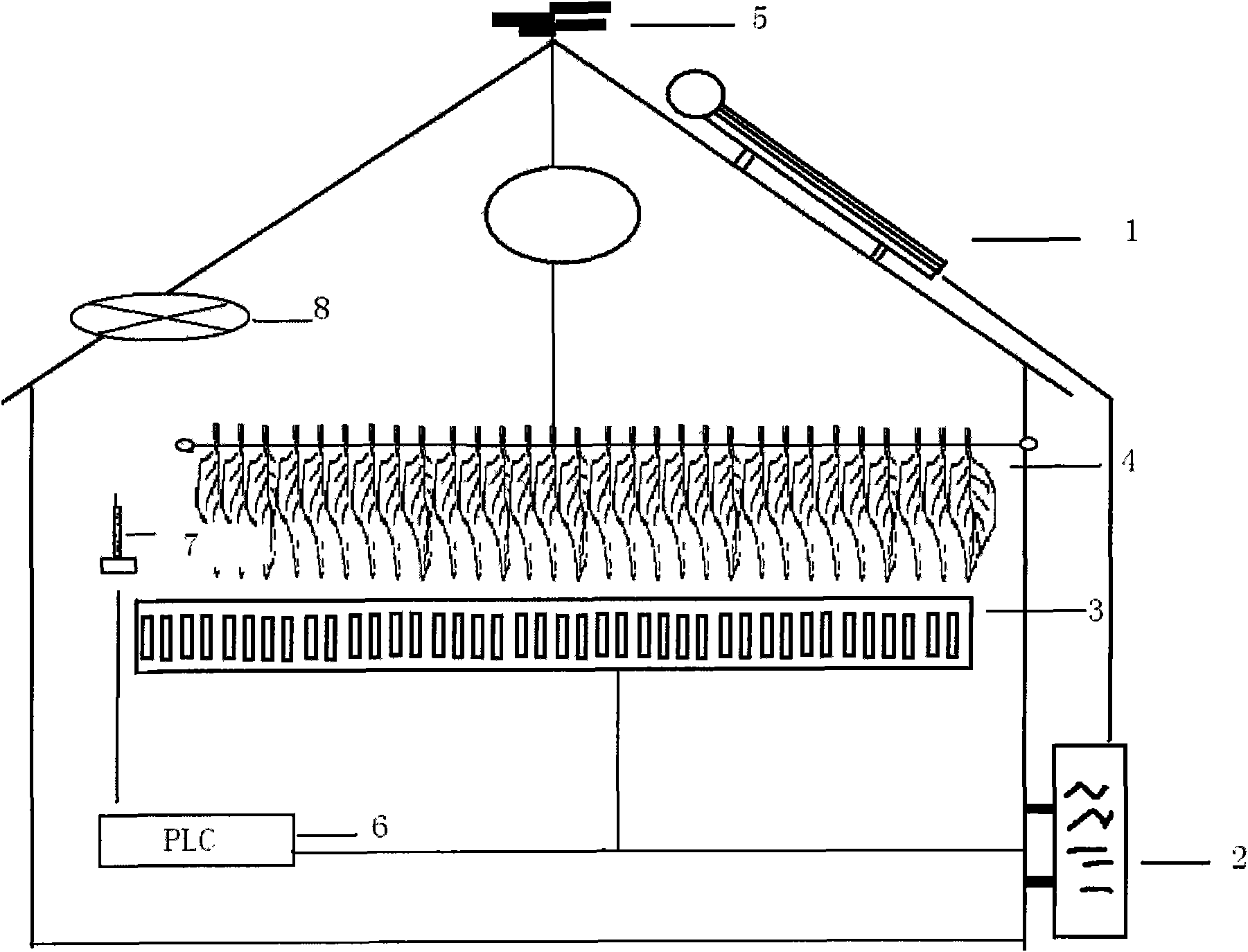

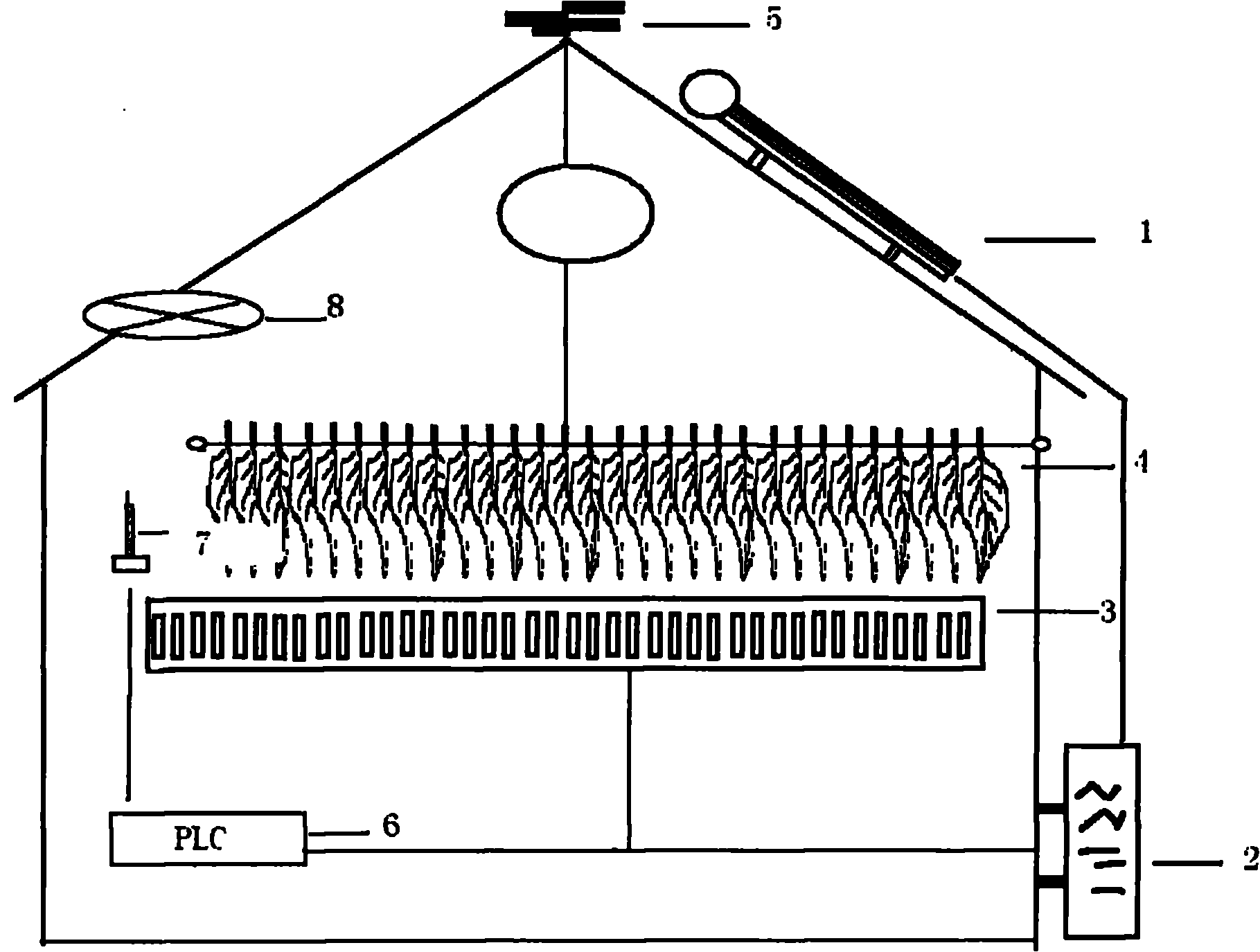

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] In the accompanying drawing, the heat collector (1) is responsible for collecting solar energy to heat the working medium, and the heated working medium flows into the water storage tank (2), and the water storage tank transfers the heat of the working medium to the heated kang (3), and the heated kang transfers the heat Discharge into the air evenly, increase the temperature, heat the tobacco leaves on the tobacco rack (4), the wind blade (5) collects natural wind to drive the tobacco rack to rotate in the smoke room, the tobacco leaves evaporate moisture into the air, and the humidifier (8) Absorb the moisture in the air in the smoke room and discharge it out of the smoke room. The temperature monitor (7) monitors the temperature change in the smoke room and feeds back the information to the PLC control terminal (6). The PLC control terminal adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com