Preparation method for 3,3,3-trifluoropropenyl methyl ether

A technology of trifluoropropenyl methyl ether and trifluoropropane, which is applied in the fields of ether preparation and organic chemistry, and can solve the problems of low reaction yield and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

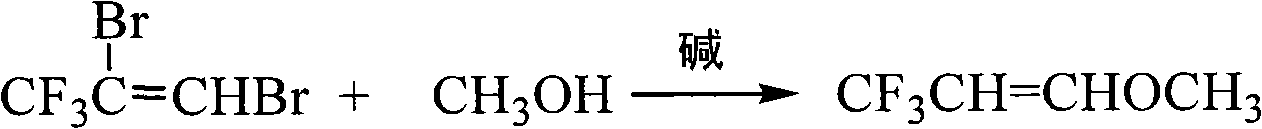

Method used

Image

Examples

Embodiment 1

[0014] Under stirring, add 96g of methanol and 80g of sodium hydroxide into the reactor, then add 128g of 1,2-dibromo-3,3,3-trifluoropropane, heat up to 70°C, react for 6h, cool to room temperature, and discharge. The reaction solution was washed three times with 100 g of water to obtain 3,3,3-trifluoropropenyl methyl ether, 44.1 g, with a yield of 70% and a purity of 98%.

[0015] Product structure identification:

[0016] MS: m / z 126 (M + ), 91(100).

[0017] IR(KBr), υ / cm -1 : 3002, 2951, 1681, 1465, 1291, 1139, 975.

[0018] 13 CNMR (CDCl 3 ), δ / ppm: 147.6 (CH, C1), 121.5 (CF 3 , C3), 93.8 (CH, C2), 55.90 (OCH3).

[0019] 1 HNMR (CDCl 3 ), δ / ppm: 6.79 (d, 1H), 4.70 (d, 1H) 3.80 (s, 3H).

[0020] The structure identification data proves that the substance obtained by the method of the present invention is indeed 3,3,3-trifluoropropenyl methyl ether.

Embodiment 2

[0022] Under stirring, add 128g of methanol and 80g of sodium hydroxide into the reactor, then add 128g of 1,2-dibromo-3,3,3-trifluoropropane, heat up to 70°C, react for 6h, cool to room temperature, and discharge. The reaction solution was washed three times with 100 g of water to obtain 3,3,3-trifluoropropenyl methyl ether, 42.8 g, with a yield of 68.0% and a purity of 98%.

Embodiment 3

[0024] Under stirring, add 128g of methanol and 120g of sodium hydroxide into the reactor, then add 128g of 1,2-dibromo-3,3,3-trifluoropropane, heat up to 70°C, react for 6h, cool to room temperature, and discharge. The reaction solution was washed three times with 100 g of water to obtain 3,3,3-trifluoropropenyl methyl ether, 43.5 g, with a yield of 69.1% and a purity of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com