Vinyl polymerization catalyst, preparation and application

A technology of ethylene polymerization and catalyst, which is applied in the field of preparation of the catalyst, which can solve the problems of high polymer subdivision content and unsatisfactory shape of magnesium-containing carrier particles, etc., and achieve the effect of narrow particle size distribution and good particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

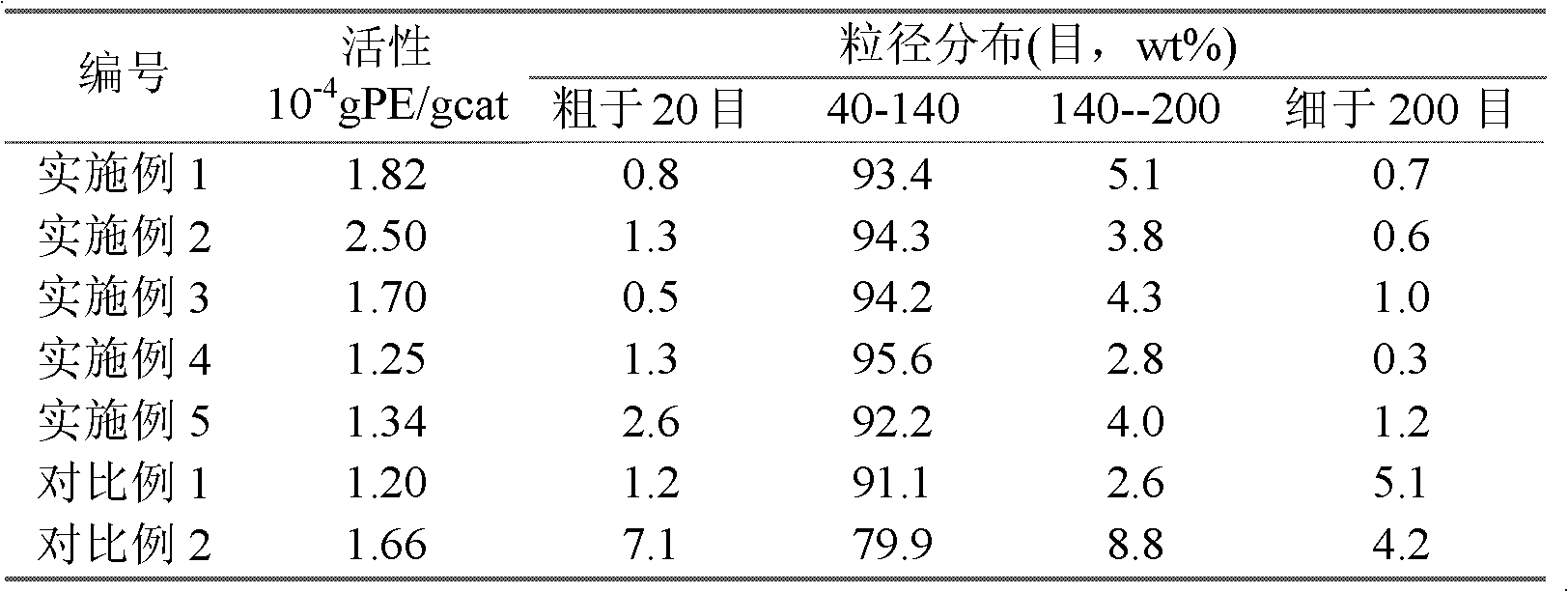

Examples

Embodiment 1

[0032] (1) Weigh 10.2 g of magnesium chloride, add 78 ml of tetrabutyl titanate, stir and dissolve at 140° C. until a transparent solution is formed, lower the temperature of the solution to room temperature, and add 200 ml of dry hexane to dilute for later use.

[0033] (2) Take 20 milliliters of the solution obtained in step (1), and slowly add the solution dropwise to a mixture of 30 milliliters of hexane and 20 milliliters of silicon tetrachloride at room temperature. The reaction was stirred for 1 hour, and the reaction was stirred for 2 hours at a bath temperature of 65° C. to obtain a catalyst suspension.

[0034] (3) The temperature of the catalyst suspension is lowered to room temperature, left to stand, settled, and washed three times with hexane, each time the consumption of hexane is 50 milliliters. Purging and drying to obtain a solid fluid powder.

[0035] The average particle size of the catalyst (D(50)): 22 microns, the particle size distribution width Span: 0...

Embodiment 2

[0037] The 20 milliliters of silicon tetrachloride in the catalyst preparation step (2) was adjusted to 20 milliliters of titanium tetrachloride, and other conditions were the same as in Example 1.

[0038] The average particle size of the catalyst (D(50)): 16 microns, the particle size distribution width Span: 1.5, the activity of the catalyst and the sieving results of the polyethylene powder are shown in Table 1.

Embodiment 3

[0040] The hexane used in the catalyst preparation step of Example 1 was adjusted to the same volume of toluene, but the same volume of hexane was still used when the catalyst was washed.

[0041] The average particle size of the catalyst (D(50)): 12 microns, the particle size distribution width Span: 0.6, the activity of the catalyst and the sieving results of the polyethylene powder are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com