Remote control converter wet spraying process method and device

A technology of wet gunning and flow control device, applied in the direction of manufacturing converters, lining repair, etc., can solve problems such as long distances in industrial applications, and achieve the effects of being conducive to environmental protection, dense materials, and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

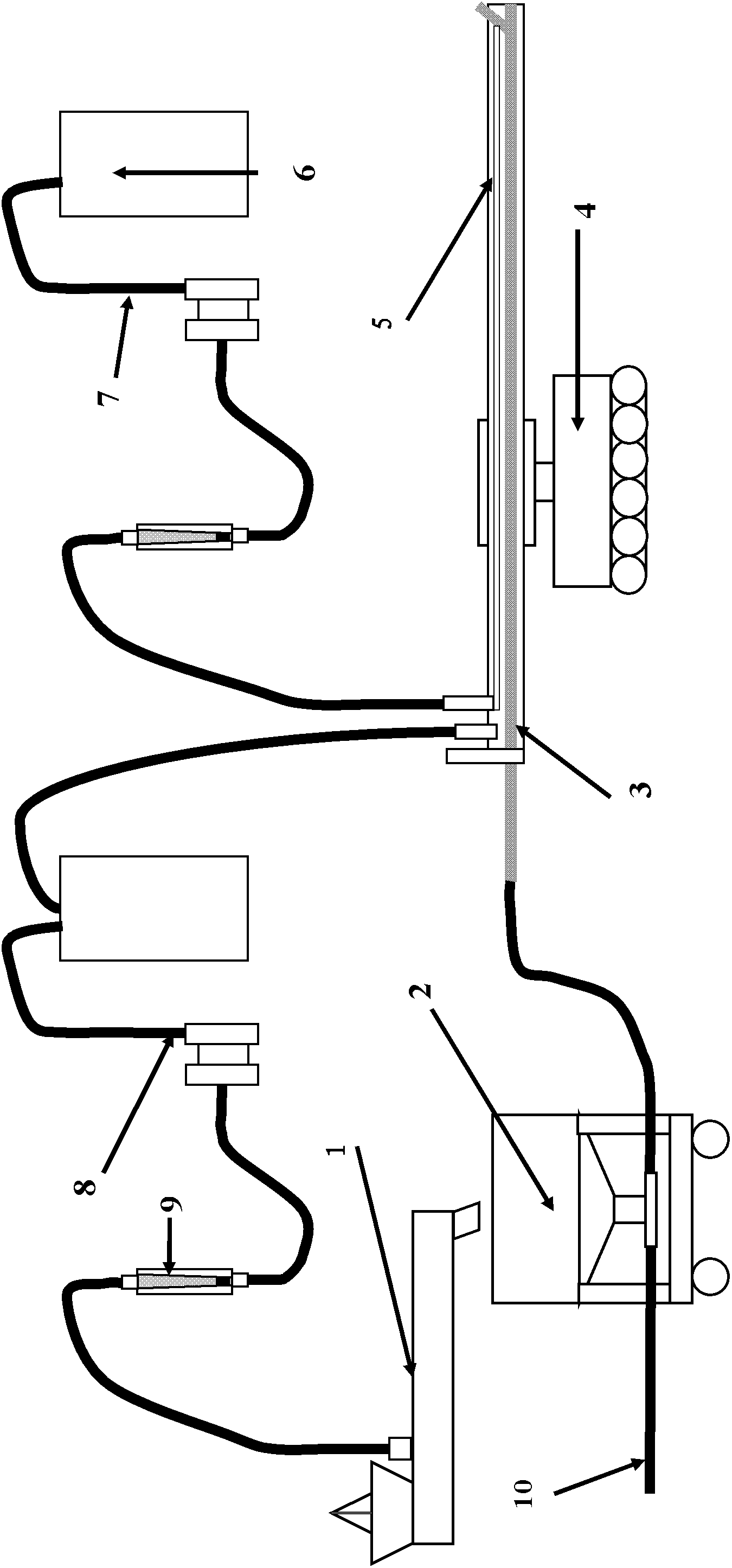

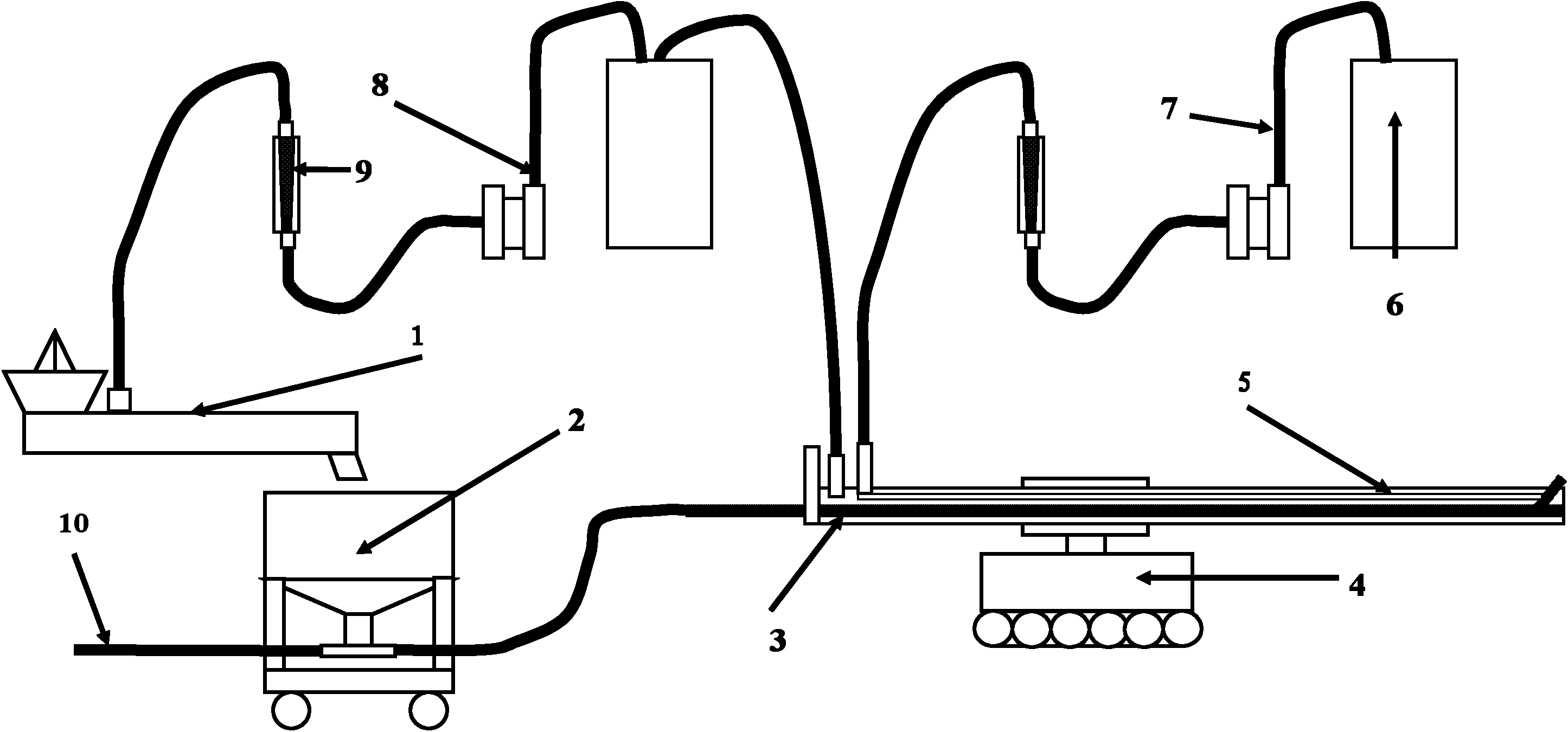

[0029] A remote control converter wet gunning device, the water supply device 8 transports the water source through the pipeline and connects the self-flowing material delivery device 3;

[0030] The water supply device 8 is connected to the flow control device 9 through a pipeline, and the flow control device 9 is connected to the stirring device 1 through a pipeline, and the feeding nozzle of the stirring device 1 is aligned with the feeding device 2;

[0031] The coagulant adding device 6 sends the coagulant to the second flow control device through the combined pipeline 7; the second flow control device sends the coagulant to the self-flowing material delivery device 3 through the pipeline;

[0032] The high-pressure gas is connected to the feeding device 2 through the intake pipe 10, and the material in the feeding device 2 is transferred to the self-flowing material conveying device 3 through the pipeline;

[0033] The self-flowing material conveying device 3 is connecte...

Embodiment 2

[0055] A remote control injection repair device of the present invention mainly includes a continuous stirring device, a water pump unit device, a self-flowing material conveying device, a conveying pipeline, a coagulant adding device, and a spray gun operating device, and the spray material with good fluidity that has been stirred with water Continuously convey and spray to the position where the furnace lining needs to be repaired.

[0056] The specific features of the present invention are that the continuous stirring device uses a continuous mixer, the flow of water is automatically controlled, the dry material transportation and wet mixing are carried out continuously and without interruption, and the movement and rotation of the gunning vehicle and the spray gun can be operated by remote control.

[0057] One end of the delivery pipeline is connected to the high-pressure air source, and the other end is connected to the spray gun; the accelerator is introduced near the sp...

Embodiment 3

[0059] A remote-controlled converter wet gunning device, using a jet repairing device, including a continuous stirring device, a self-flowing material distribution device, a material delivery pipeline, a water-cooled spray gun with a remote control device, an accelerator delivery pump, a metering device and pipelines. The injection material with good fluidity that has been stirred with water is transported and injected to the position where the furnace lining needs to be repaired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com