Automatic separation method for front and rear surface reflected light spots in surface shape detection system

A technology for detecting the front and rear surfaces and surface shapes, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of smearing on the rear surface of optical components, and achieve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

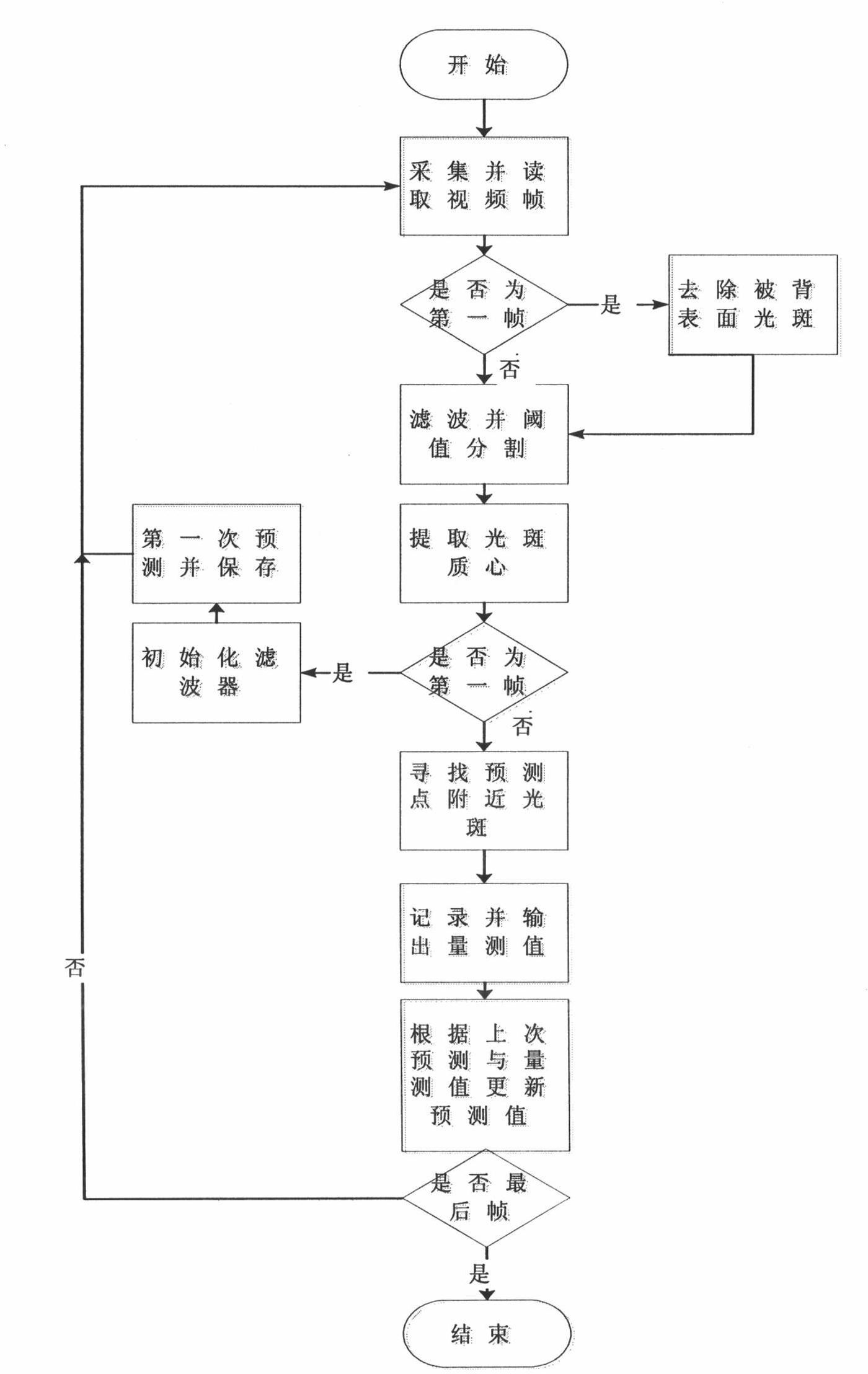

[0036] Separation method of front and rear reflection spots based on kalman filter

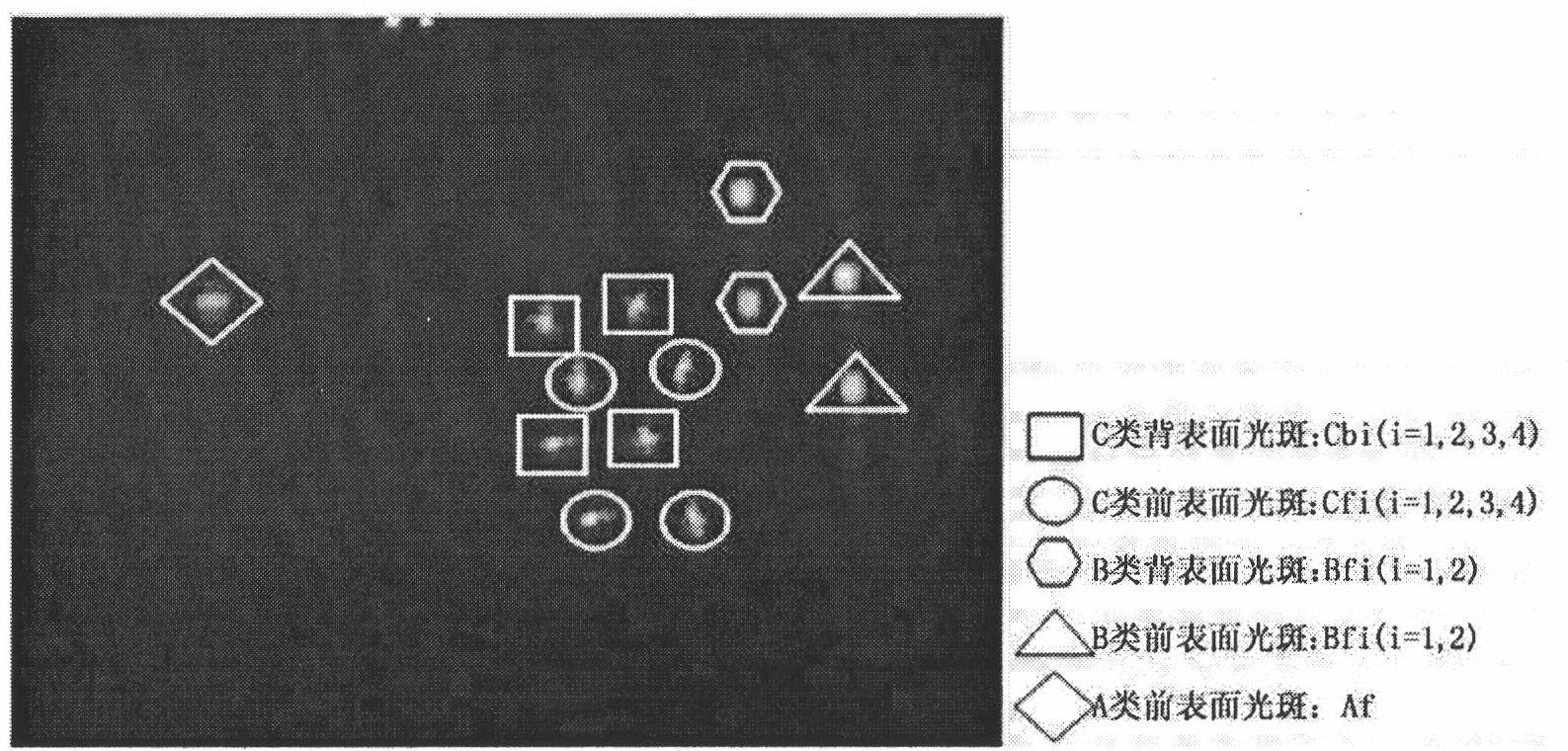

[0037] During the surface shape test, the reflected light spots on the back surface are artificially erased from the acquired first frame image, and all the reflected light spots on the front surface are tracked, so as to achieve the purpose of classifying the front and rear surface light spots. refer to figure 2 , its main steps are:

[0038] A1: The CCD collects the spot image F1 reflected by the front and rear surfaces; if it is the first frame image, manually erase the reflected spot on the back surface to select the correct target for subsequent tracking;

[0039] A2: Use the method of background subtraction and multiplicative filtering to filter out noise and perform iterative threshold segmentation to separate laser spots; obtain binary image F2;

[0040] A3: Detect all the light spots in the image F2, if there is adhesion of the light spots, separate the sticking light spots, and ex...

Embodiment 2

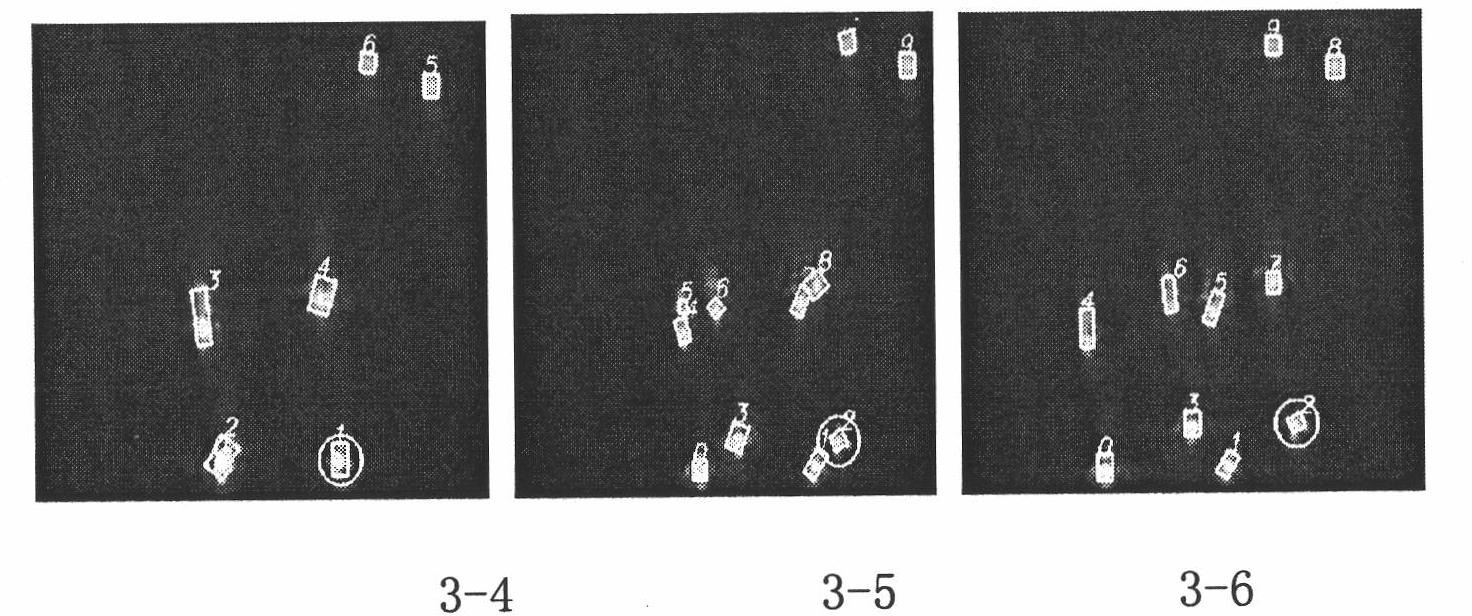

[0057] The tracking effect based on the Kalman filter is as follows: image 3 , image 3 The light spots in the middle rectangular frame are the detected light spots, and the light spots in the circular frame are the tracking front surface reflection spots. It can be found that in the case of the front and rear surface reflection spots, the tracking algorithm based on the Kalman filter can correctly distinguish For the light spots reflected on the front surface, the statistics of multiple experimental results show that the tracking accuracy rate is above 95%.

Embodiment 3

[0059] Experimental results of overlapping spot separation based on distance transformation

[0060] In the experiment, three types of laser spots were overlapped and separated: (1) The spots with basically the same size and not serious overlapping ( Pic 4-1 ); (2) overlapping spots of inconsistent size ( Figure 4-2 ); (3) Spots with basically the same size and serious overlapping ( Figure 4-3 ). in, Pic 4-1 , Figure 4-2 and Figure 4-3 From left to right in the middle are the original image, the segmentation effect image, the circle center area image, and the separation result image. Experimental results show that the method of the present invention can well realize the separation of overlapping light spots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com