Digital liquid level sensor

A liquid level sensor and sensor technology, applied in liquid level indicators for physical variable measurement, etc., can solve problems such as inability to match subsequent digital processing circuits, and achieve the effects of easy replacement, low cost, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

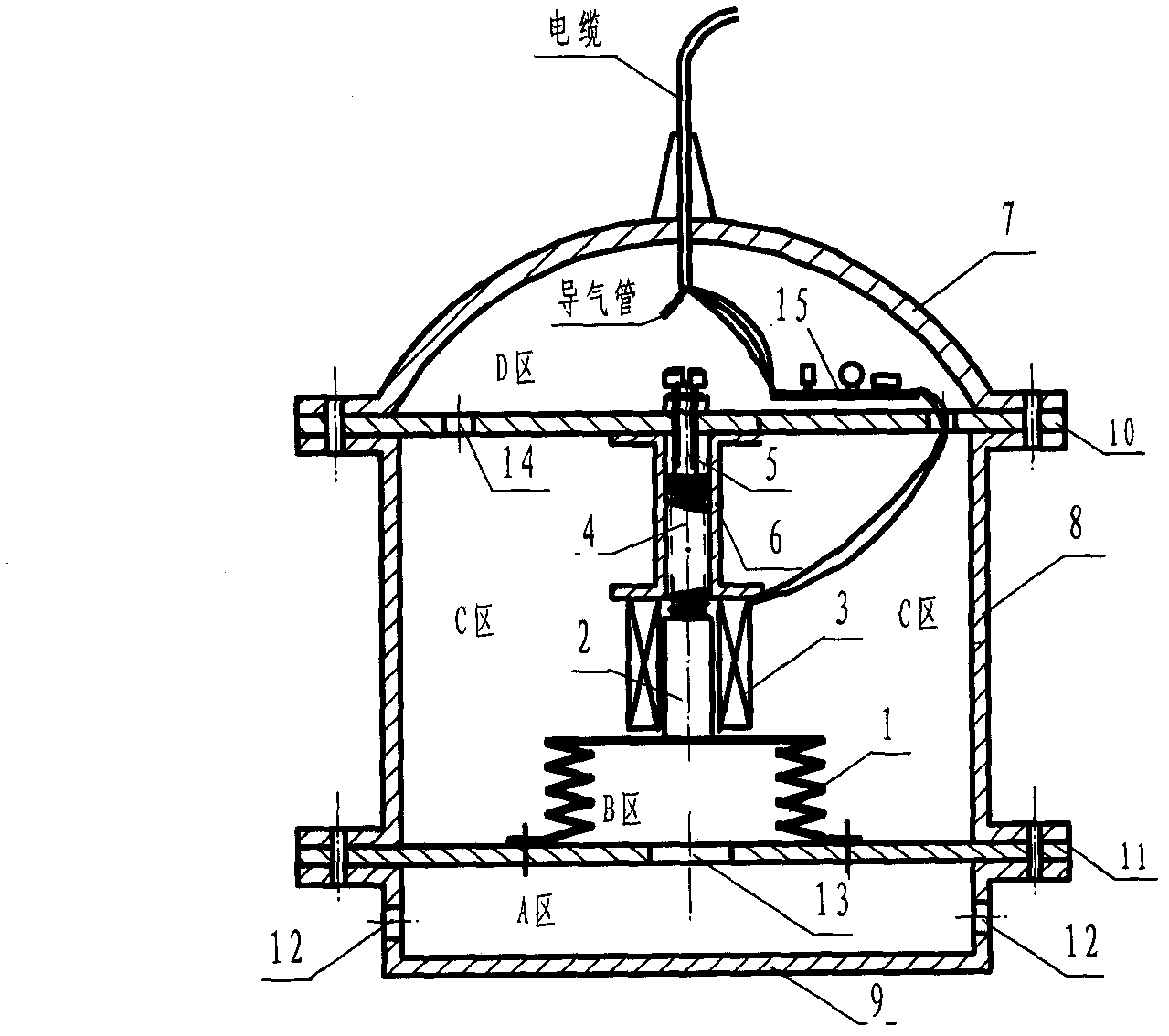

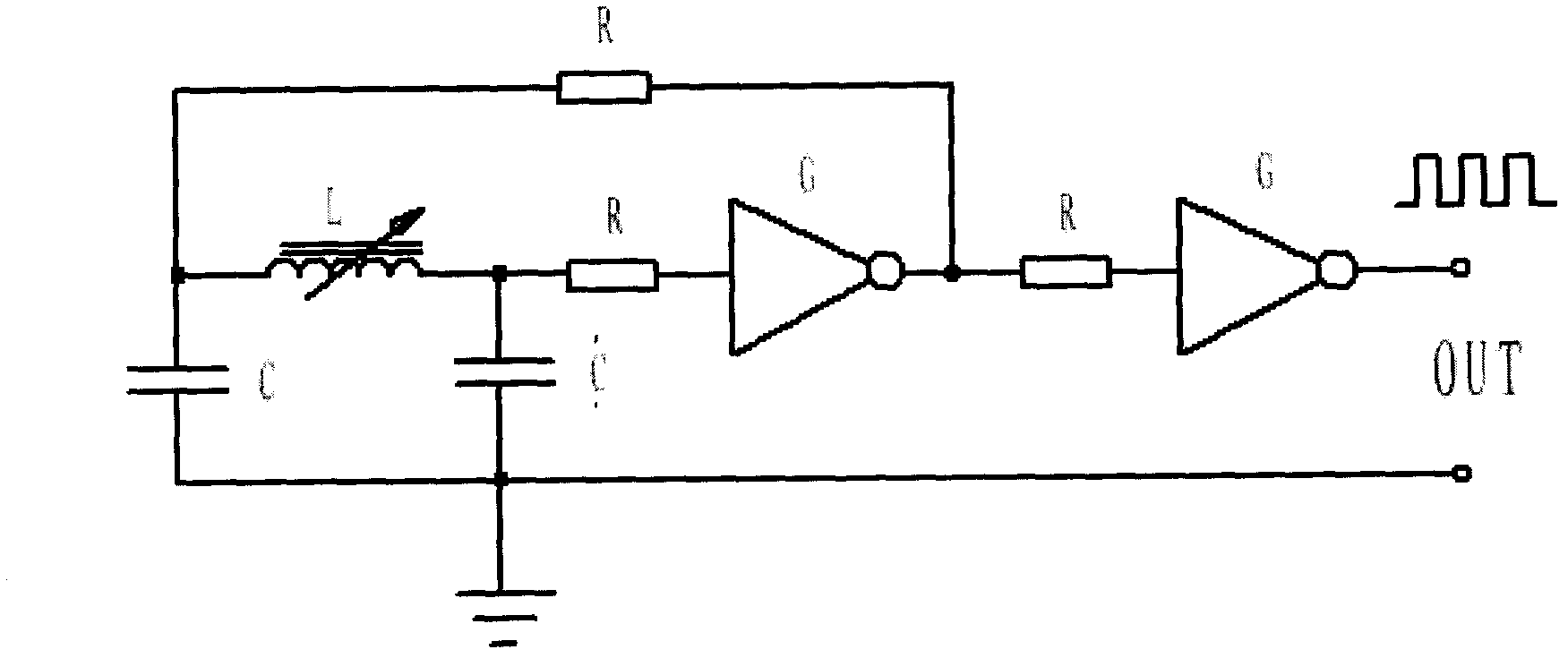

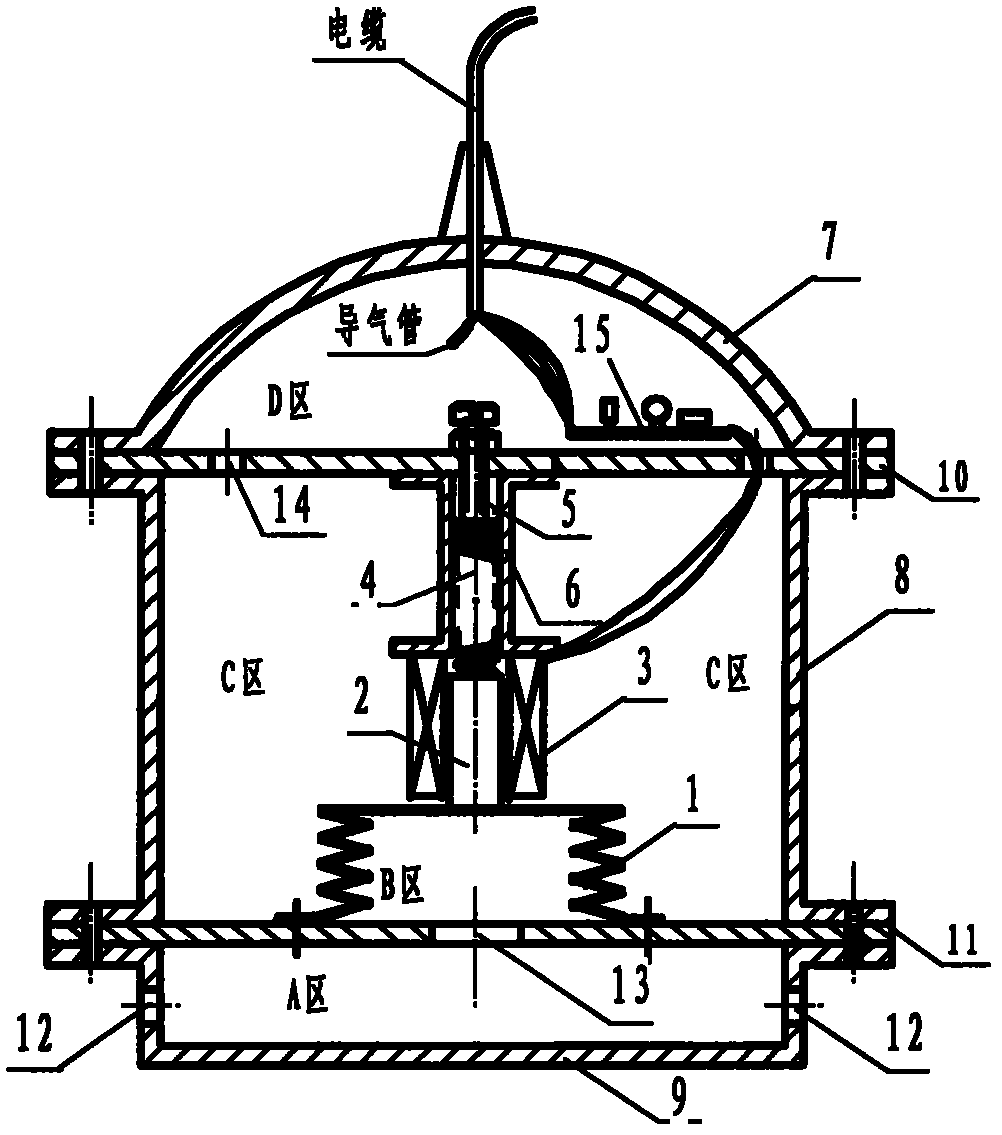

[0021] Such as figure 1 , a digital liquid level sensor of the present invention is composed of a sensing part, a housing and a transmitter 15, and the sensing part is composed of a rubber mold box 1, a magnetic core 2, a coil 3, a spring 4 and an adjusting screw 5, wherein The rubber mold box 1 is a rubber elastic cavity that stretches up and down. The magnetic core 2 is fixed on the upper end of the rubber mold box 1 to make it integrated. The lower end of the mold box 1 is fixed on the center of the lower support plate 11. 6 is fixed on the center of the upper support plate 10, the magnetic core 2 penetrates the coil 3, the spring 4 withstands the upper end surface of the magnetic core 2, adjusts the adjustment screw 5 to adjust the pressure of the spring 4 on the magnetic core 2, when there is a force When placed at the upper end of the inner cavity of the rubber mold box 1, the magnetic core 2 will move up and down in the coil 3; The cable of the trachea is drawn from th...

Embodiment approach 2

[0030] A digital liquid level sensor of the present invention is applied on a certain water storage tank. According to the actual height of the water storage tank of 10m, the adjusting screw 5 is adjusted so that the maximum range of the digital liquid level sensor is 9.5m. According to the output frequency f m =36kH and f 0 = 3.16kH to calculate the pulse equivalent, pulse equivalent = 9500 / (36000-3160) = 0.29mm / pulse, the same output frequency decreases by one pulse, the water level increases by 0.29mm; on the contrary, each time the output frequency increases by one pulse, the water level decreases by 0.29mm, Store the pulse equivalent of 0.29mm / pulse into the intelligent digital display as the basis for calculating the water level. Others are the same as Embodiment 1.

Embodiment approach 3

[0032] The application of a digital liquid level sensor of the present invention on an oil storage tank, the difference between measuring the oil level and measuring the water level is that the sensor must be resistant to oil when measuring the oil level, and at the same time must have explosion-proof measures. The rubber mold box 1 is replaced with an oil-resistant Rubber mold box, transmitter 15 power supply adopts intrinsically safe power supply. Others are the same as Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com