Large generator based local discharge ultrasonic distribution characteristic sensor setting analysis method

A technology of partial discharge and distribution characteristics, applied in the direction of testing dielectric strength, etc., can solve the problem of inability to locate partial discharge points, and achieve the effect of reducing maintenance and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

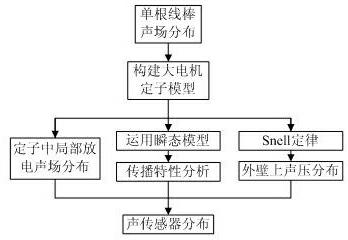

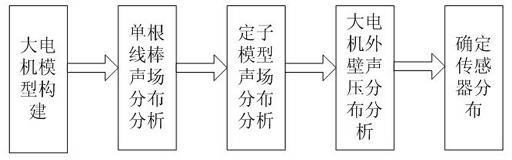

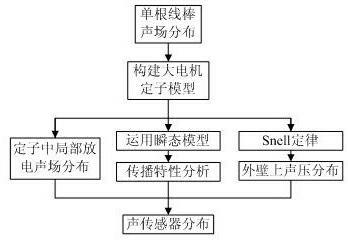

[0027] figure 1 The block diagram of the structure principle of the present invention is shown. In principle, the method mainly includes the analysis of the sound field distribution of a single wire rod, the construction of a stator model of a large motor, the distribution of the partial discharge sound field in the stator, the analysis of sound propagation characteristics, and the distribution of sound pressure on the outer wall of a large motor. And the distribution of acoustic sensors is configured in several large step modules.

[0028] The partial discharge ultrasonic signal of a large electric machine is the analysis object of the whole analysis method. Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com