P(MAh-AA)-PEG4000-based gel polymer electrolyte and preparation method thereof

A gel polymer and polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the unsatisfactory film-forming properties, thermal properties and dimensional stability of polyacrylate gel polymer electrolytes, etc. problem, to achieve the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

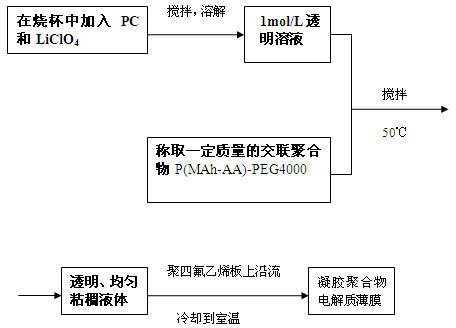

Embodiment 1

[0022] Embodiment 1: lithium perchlorate (LiClO 4 ) was dissolved in propylene carbonate (PC) to prepare an organic solution with a concentration of 1mol / L; then 20g of polymer was dissolved in 80g of this organic solution, and stirred evenly at 50°C; then, the obtained homogeneous viscous The thick liquid flows along the polytetrafluoroethylene plate, and after cooling, the condensed polymer electrolyte membrane GPE-20 is obtained.

Embodiment 2

[0023] Embodiment 2: lithium perchlorate (LiClO 4 ) was dissolved in propylene carbonate (PC) to prepare an organic solution with a concentration of 1mol / L; then 30g of polymer was dissolved in 70g of this organic solution and stirred evenly at 50°C; then, the obtained homogeneous viscous The thick liquid flows along the polytetrafluoroethylene plate, and after cooling, the condensed polymer electrolyte membrane GPE-30 is obtained.

Embodiment 3

[0024] Embodiment 3: lithium perchlorate (LiClO 4 ) was dissolved in propylene carbonate (PC) to prepare an organic solution with a concentration of 1mol / L; then 40g of polymer was dissolved in 60g of this organic solution and stirred evenly at 50°C; then, the obtained homogeneous viscous The thick liquid flows along the polytetrafluoroethylene plate, and after cooling, the condensed polymer electrolyte membrane GPE-40 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com