Liquid-cooled radiating external rotor motor

An external rotor motor, liquid-cooled heat dissipation technology, applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of inability to dissipate heat from the stator core, difficulty in heat dissipation of the motor, and low heat dissipation efficiency, and achieve Simple structure, good cooling effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

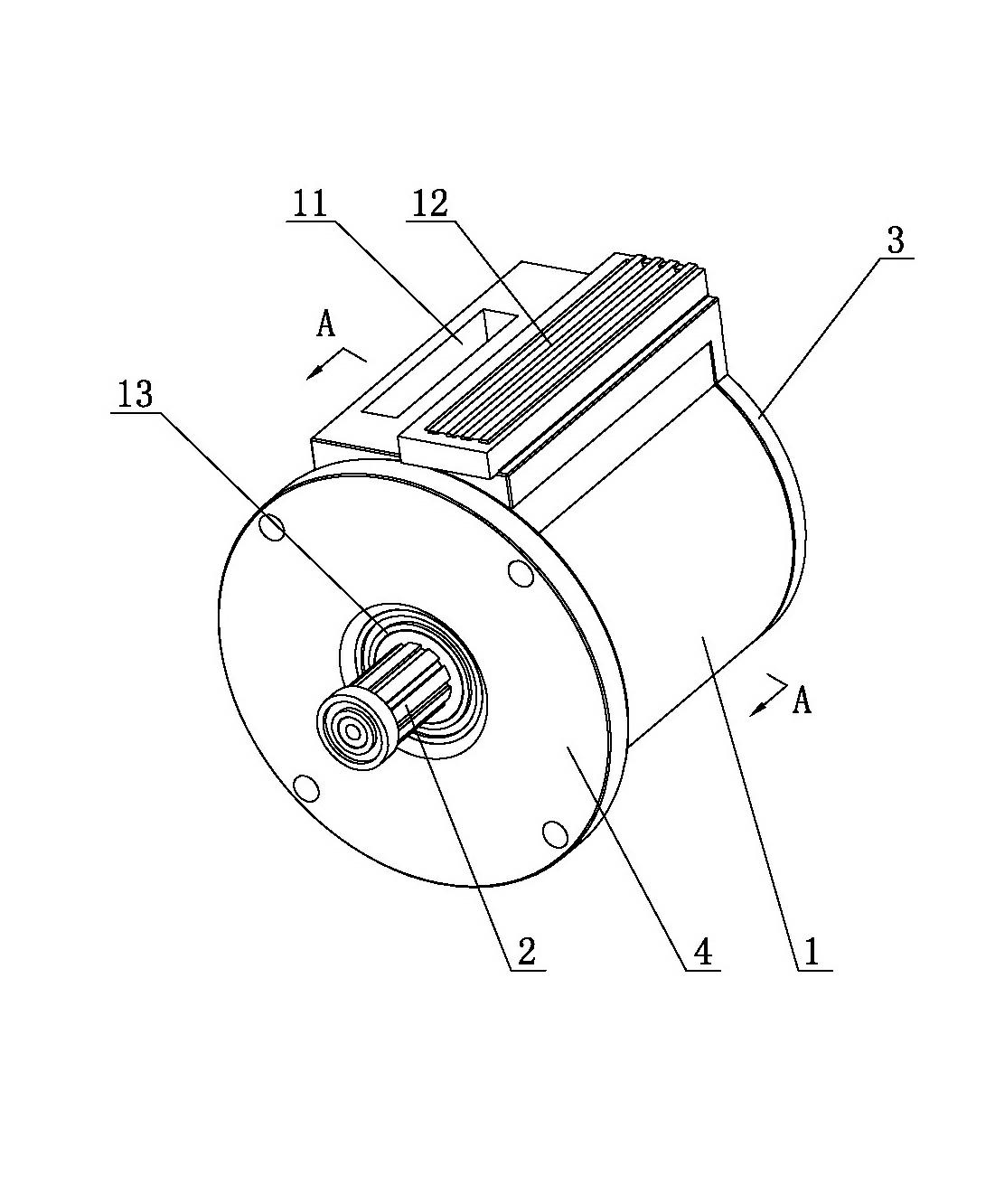

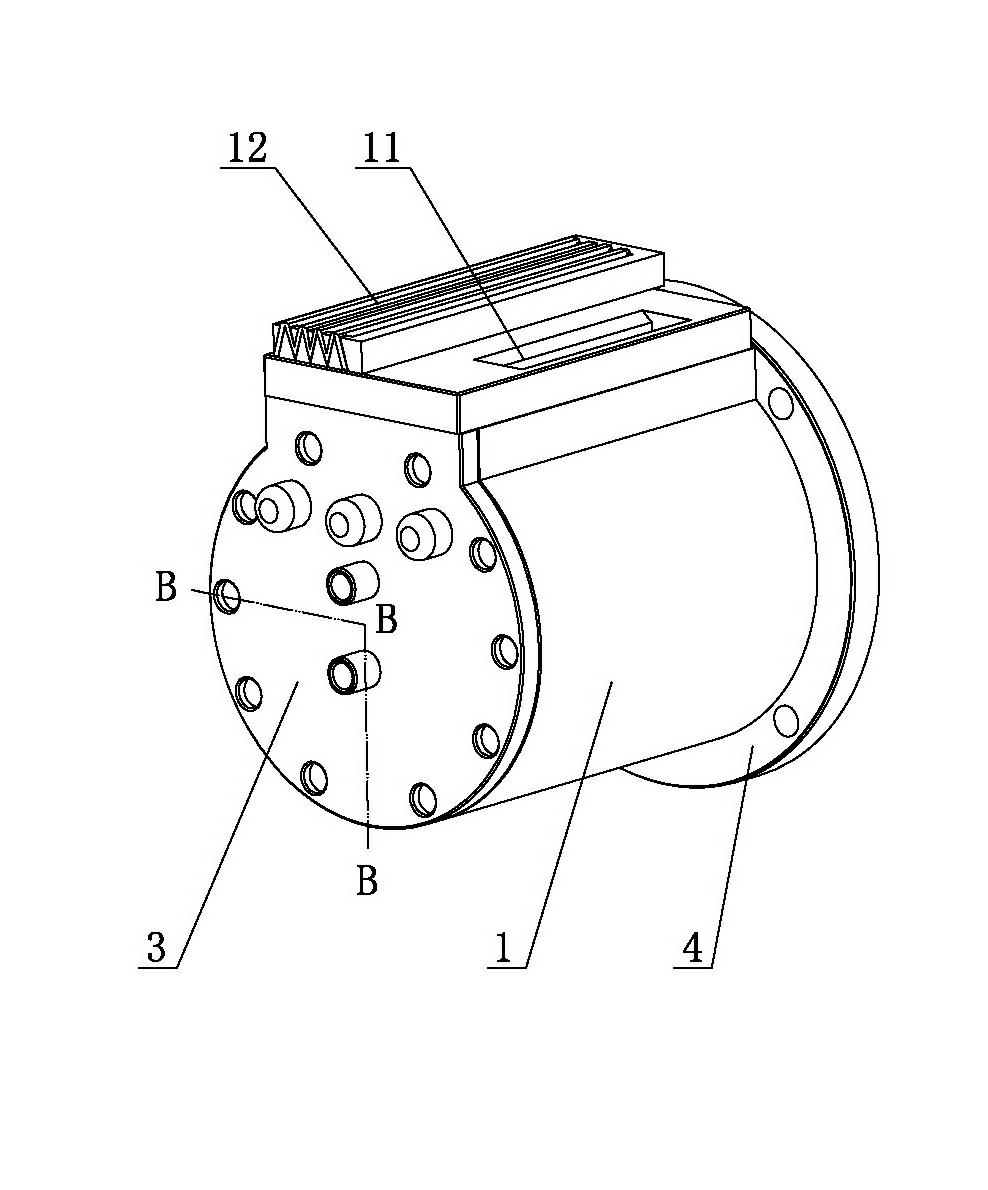

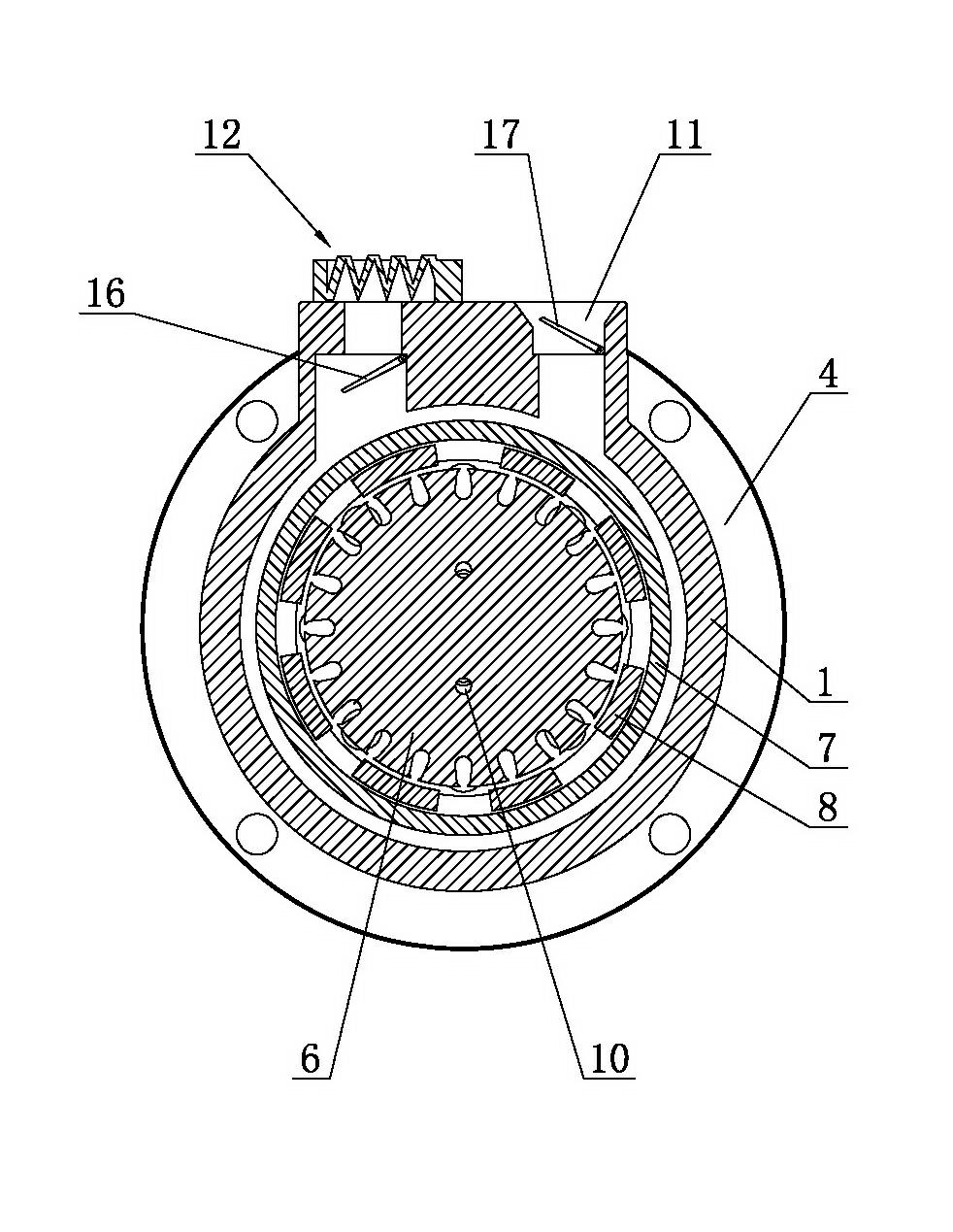

[0023] Such as Figure 1 to Figure 6 Shown is the first embodiment of the liquid-cooled and heat-dissipating outer rotor motor of the present invention, including a housing 1, a main shaft 2, a rear seat 3 connected to the rear of the housing 1, and a front seat connected to the front of the housing 1. Cover 4, the main shaft 2 is socketed on the front cover 4, the inner end of the main shaft 2 is located in the cavity of the housing 1, the inner side of the rear seat 3 is provided with a mounting base 5, and the mounting base 5 is equipped with a stator iron core 6, the stator core 6 is wound with a coil (not shown in the figure); the inner end of the main shaft 2 is provided with a drum 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com