Method for bonding upper and lower magnetic cores of module power supply

A module power supply and magnetic core technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of discontinuous process, many operator demands, and damage to the edge of the magnetic core, and achieve the effect of reducing the defect rate of inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with preferred specific embodiments.

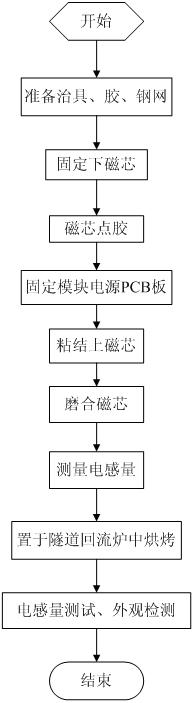

[0016] like figure 1 As shown, the magnetic core bonding method of the module power supply of this embodiment includes the following steps:

[0017] 1) Preparation stage

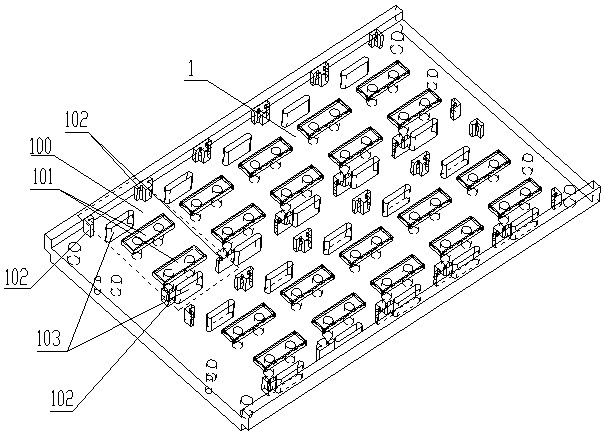

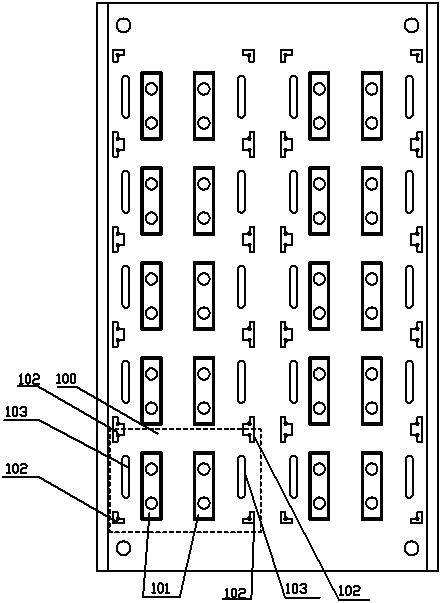

[0018] Prepare glue and fixtures. The structure of the fixture is as figure 2 , 3 As shown, the jig of this embodiment is a piece of aluminum plate 1. Ten module power supply fixing units 100 are arranged on the aluminum plate 1. The fixing unit 100 includes two magnetic core fixing slots 101 corresponding to the size of the lower magnetic core. The module power supply The two lower magnetic cores can be respectively fixed in the two magnetic core fixing grooves 101; the four corners of the fixing unit 100 are respectively provided with a module power supply PCB board fixing column 102, and the fixing unit 100 is also provided with two modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com