Manufacturing method for fish paste products

A manufacturing method and technology of fish meat, applied in the field of cooked aquatic food, taste improvement of cooked aquatic food, and preparations for cooked aquatic food, can solve the problem of low gel forming ability, achieve the effect of inhibiting the reduction of physical properties and strong colloidal strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

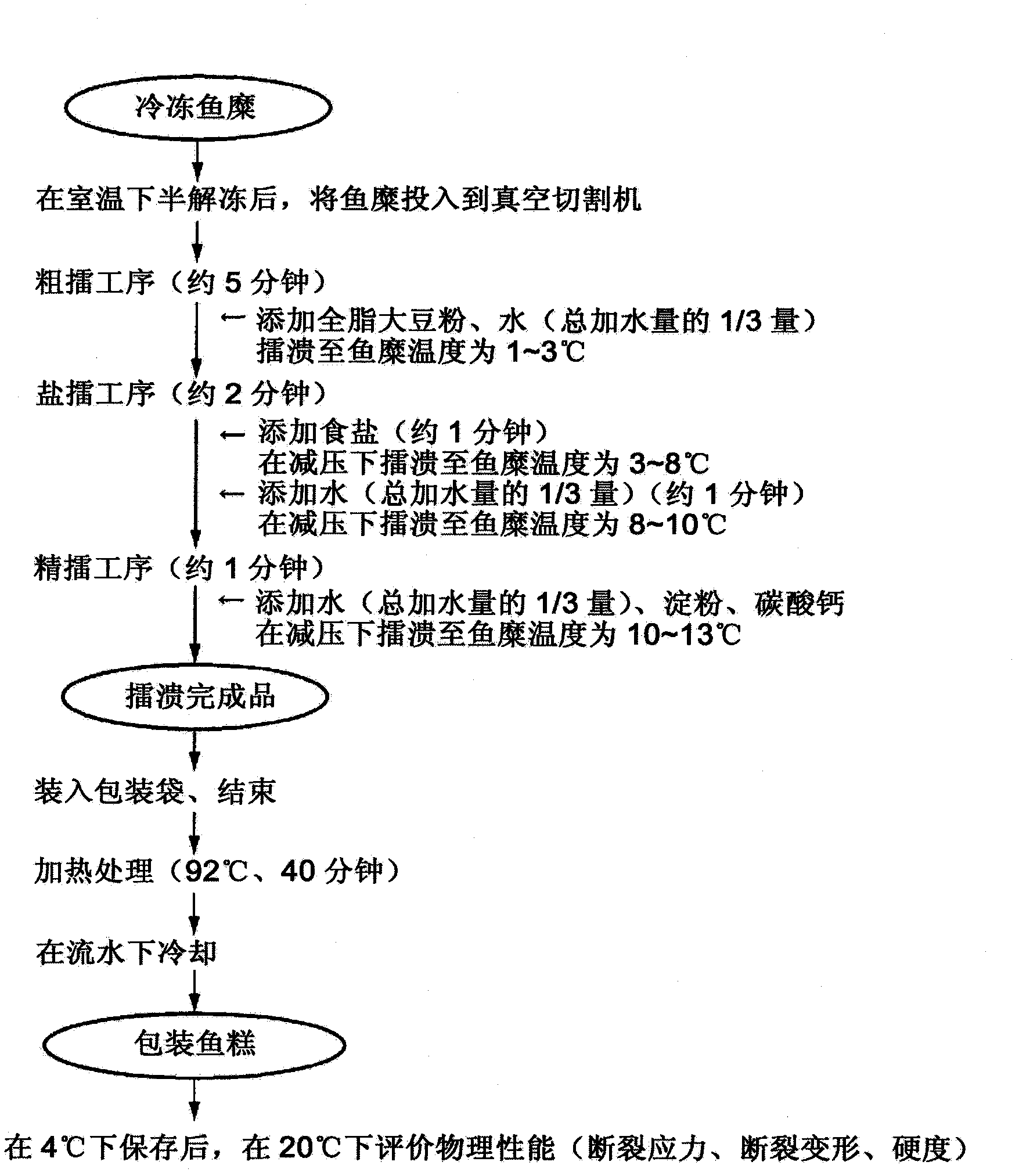

[0176] (1) Packaged Kamaboko Test Groups 1-6

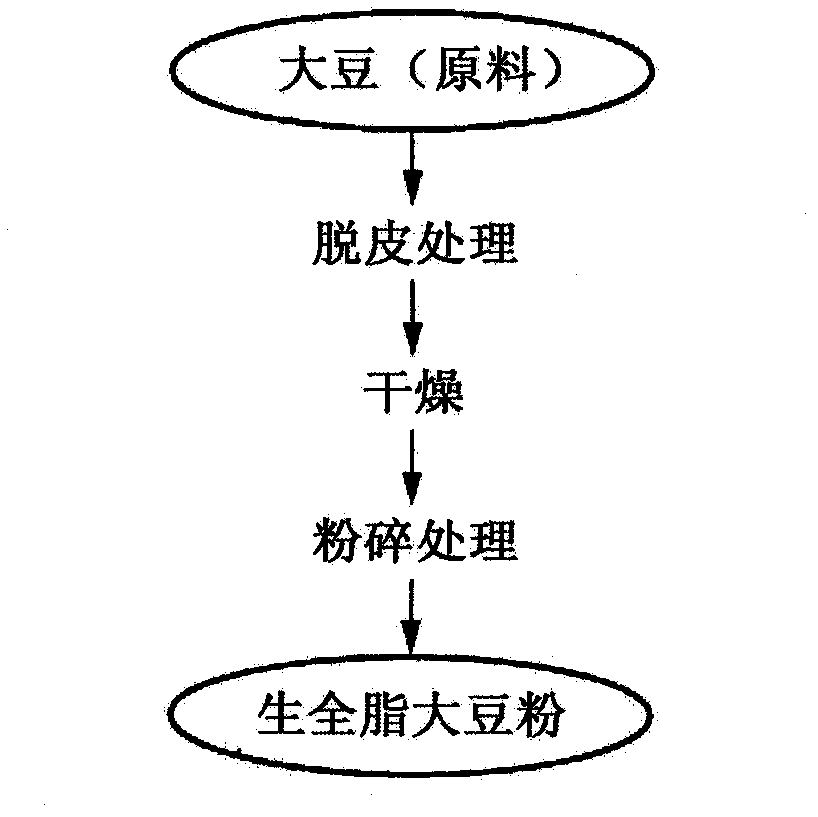

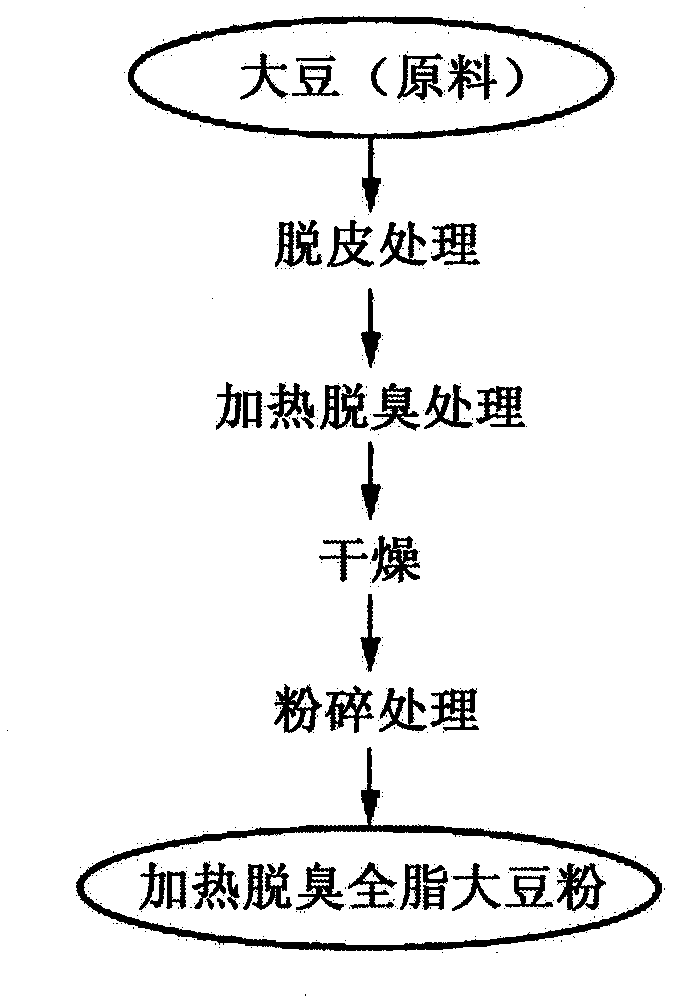

[0177] Use Alaska cod surimi KA (manufactured by American Seafoods, KAgrade, the fish species ratio in the fish meat is 100% by mass of Alaska cod) as surimi, with Table 1 (without adding starch, without adding calcium salt) and Table 3 (adding starch , without adding calcium salt), use the methods of Production Methods 1 to 4 described later ( Figure 1~4 The specific process diagrams are shown in the figure) to make packaged fish cakes. The physical properties of the obtained packaged kamaboko were evaluated by the methods described later.

[0178] The full-fat soybean flour A used in the blending was raw full-fat soybean flour (manufactured by Nissin Oilio Group Co., Ltd., trade name: Soyafurawa-NSA, trypsin inhibitor activity: 41.7 TIU / mg). Full-fat soybean flour B is a heat-deodorized full-fat soybean flour (Nisshin Oyrio Glupp Co., Ltd. trial product, trypsin inhibitor activity: 38.2 TIU / mg). Such as figure 2 As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com