Process for coating anti-electromagnetic-interference coating of non-metallic composite material

An anti-electromagnetic interference and composite material technology, applied in coatings, electrical components, magnetic field/electric field shielding, etc., can solve the problems of low adhesion of conductive metal films, poor adhesion of coating layers, and high curing temperature to achieve excellent performance Anti-electromagnetic interference performance, bright surface, dense and uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in further detail with reference to the accompanying drawings and embodiments, but it is not used as a basis for any restriction on the present invention.

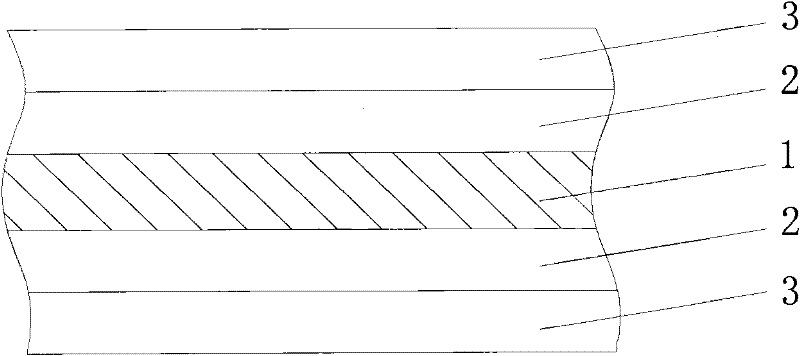

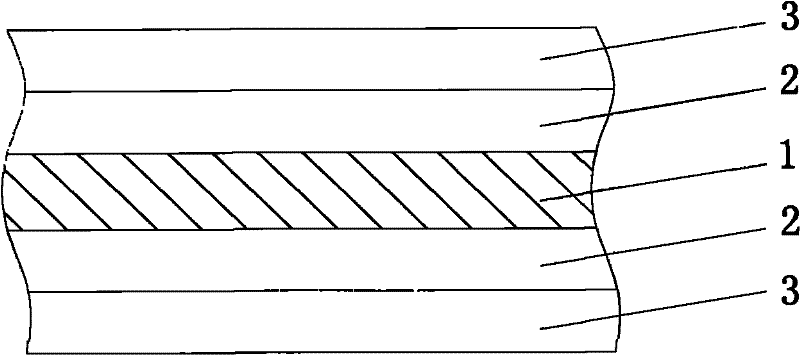

[0021] The invention provides a composite material surface anti-electromagnetic interference electromagnetic shielding paint coating process. Its working principle is to first coat a transition layer between the surface of the non-metal composite material and the anti-electromagnetic interference coating, and then on the transition layer The anti-electromagnetic interference electromagnetic shielding paint layer is coated, and the coated transition layer can well control the film formation and adhesion of the anti-electromagnetic interference coating, including the following process steps:

[0022] a) Surface treatment of parts:

[0023] Clean the surface of non-metallic composite parts with absolute ethanol to remove stains and release agents on the surface of the parts. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com