Ultralow-pressure membrane separation device for desalinating bitter and salty water

A technology for desalination and membrane separation of brackish water, applied in seawater treatment, general water supply conservation, chemical instruments and methods, etc., can solve problems such as high raw material requirements, consumption, and large fluctuations in product water quality, and achieve simplified pretreatment The effect of technology and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

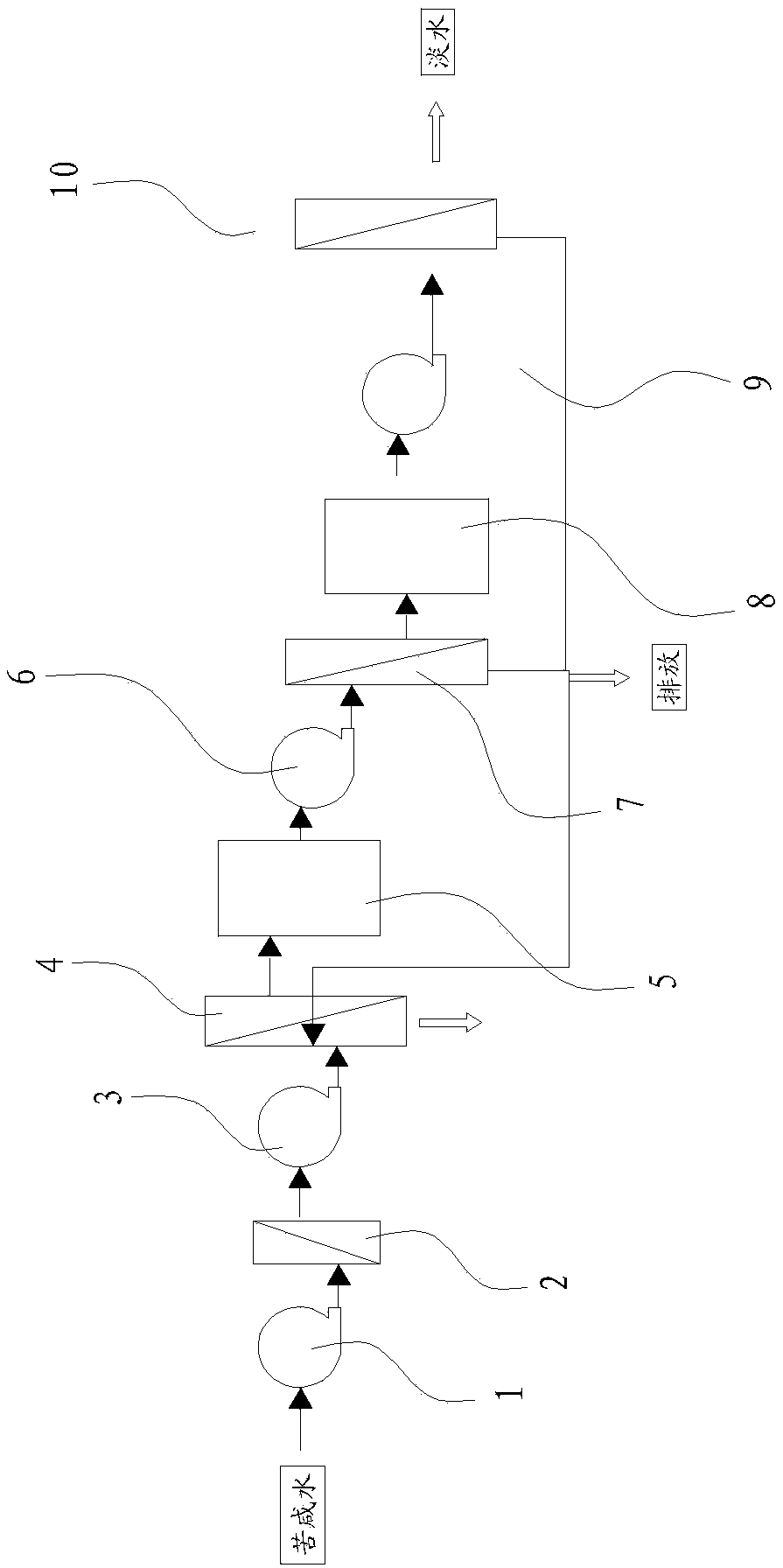

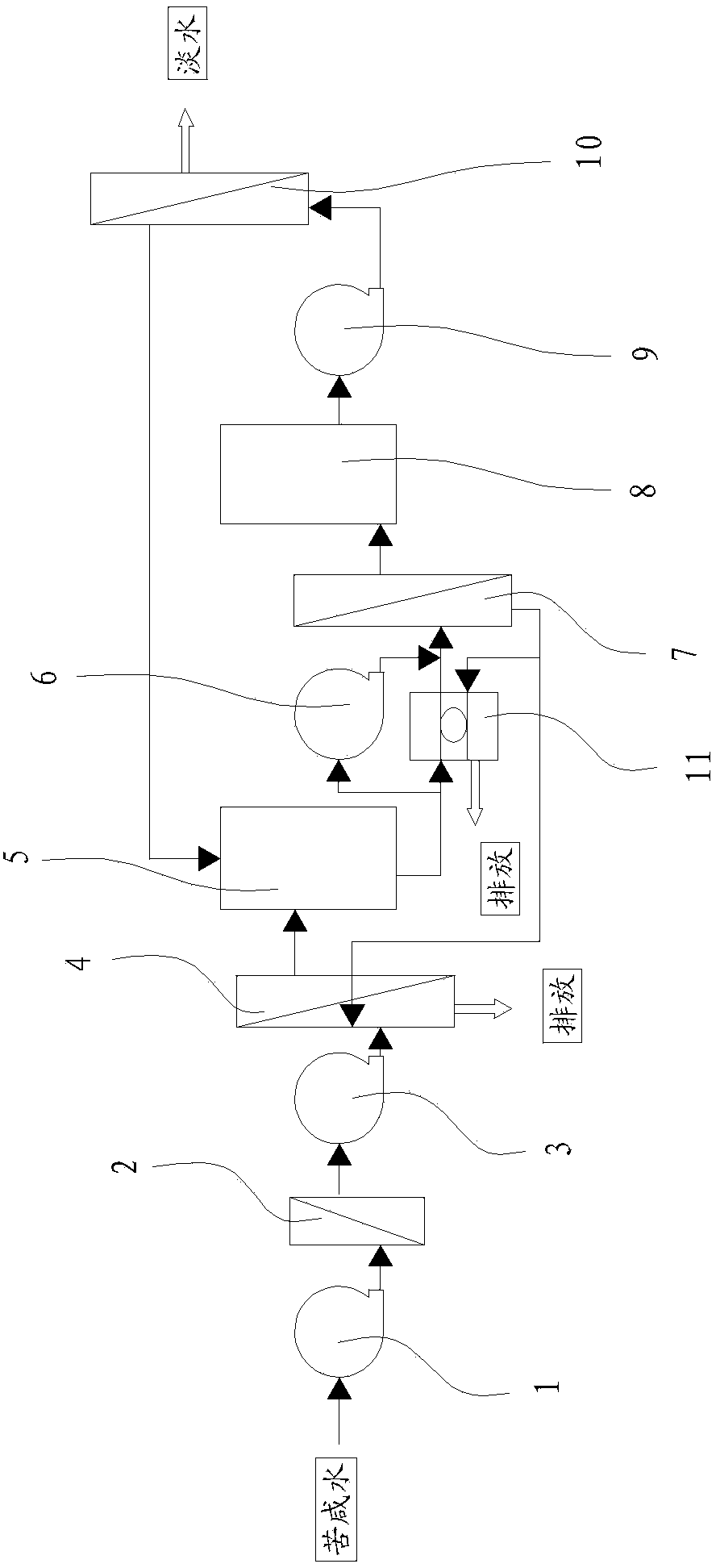

[0025] Example: see figure 1 , an ultra-low pressure brackish water desalination membrane separation device, comprising a precision filter 2, an ultrafiltration membrane system 3, an ultrafiltration membrane dialysis tank 5, a nanofiltration membrane system 7, a nanofiltration membrane dialysis tank 8, and a reverse osmosis membrane system 10 , pumps and pipelines connecting each part; the precision filter 2 is connected with the brackish water delivery pump 1, the precision filter 2 is connected with the ultrafiltration membrane system 4 through the circulation pump 3, and the ultrafiltration membrane system 4 is connected with the dialysate To the ultrafiltration dialysis tank 5, the ultrafiltration dialysate is connected with the nanofiltration membrane system 7 through the booster pump 6, and the dialysate of the nanofiltration membrane system is connected to the nanofiltration dialysis tank 8, and the nanofiltration dialysis tank 8 passes through the booster pump 9 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com