Suspended-type gear speed reducer

A technology of gear reduction and two-stage gear reduction, which is applied in the field of suspended gear reducers, can solve the problems of heavy bearing capacity of the output hollow shaft bearing, affecting the service life of the bearing, and poor heat dissipation function, so as to reduce the weight of the box and reduce the thermal energy Dissipates quickly and lowers the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

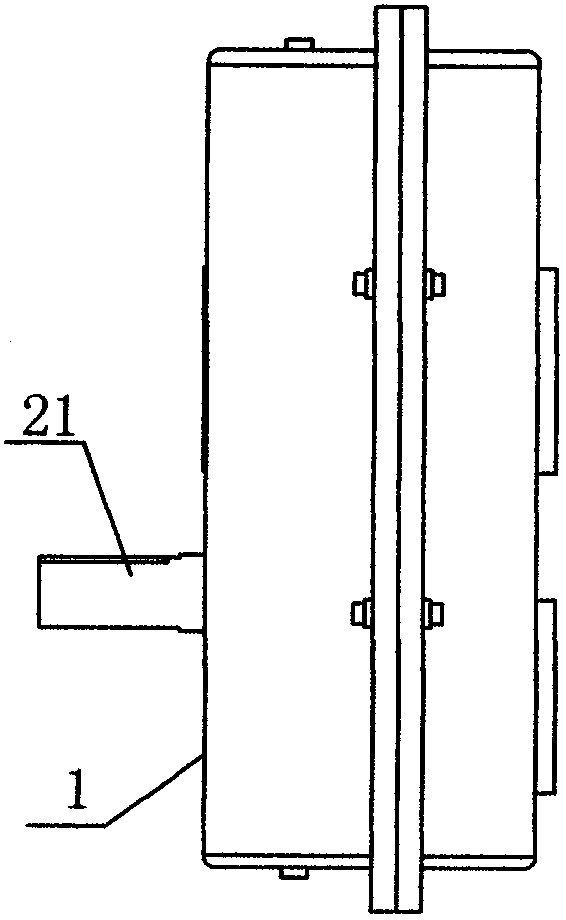

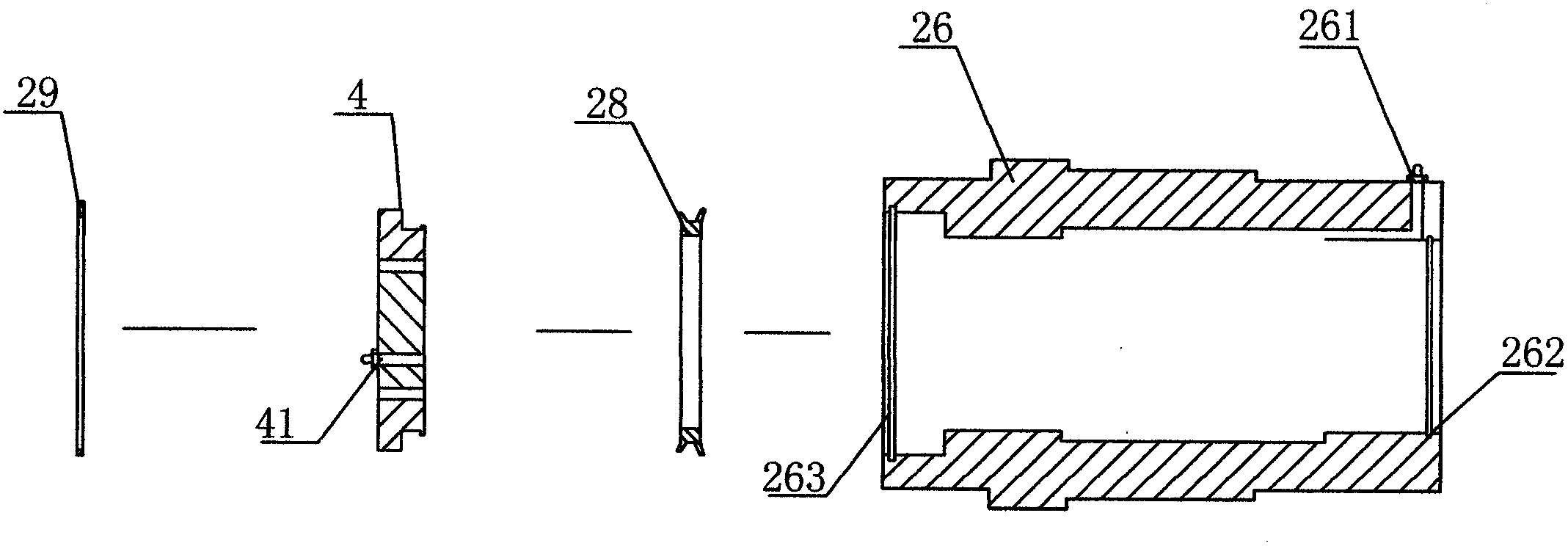

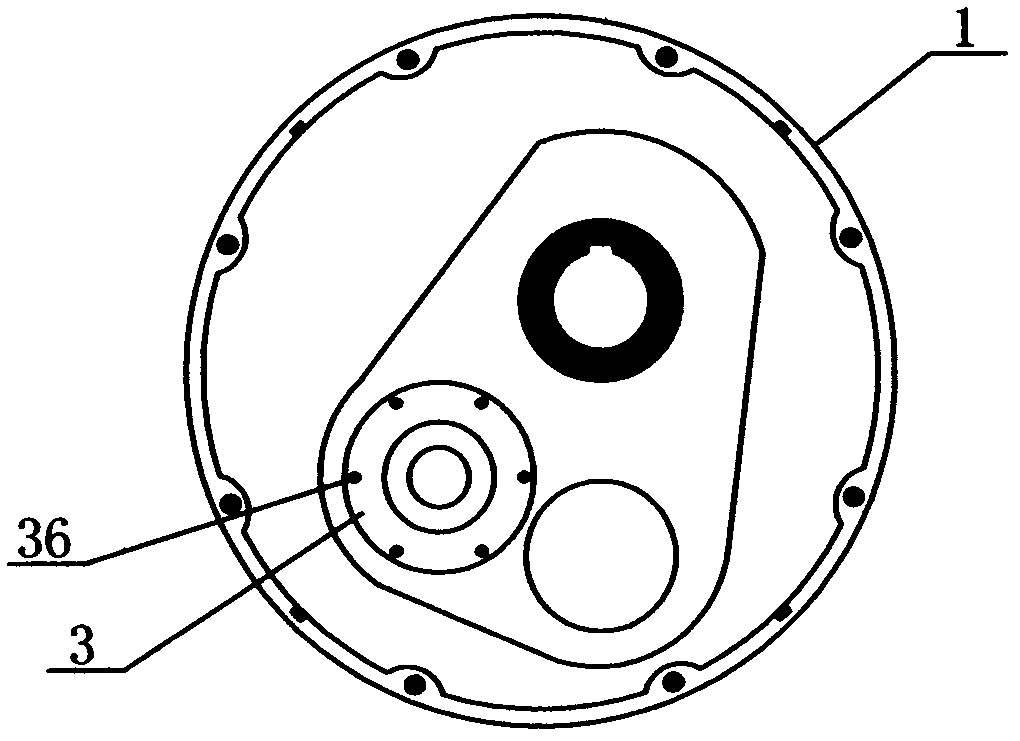

[0026] Such as Figure 1-4 , 7, the present invention is a suspension gear reducer, the structure of which includes a box body 1 made of die-cast aluminum alloy material that is easy to dissipate heat, and a two-stage gear reduction mechanism arranged in the box body 1, the two The stage gear reduction mechanism includes an input shaft 21, a first driving gear 22 installed on the input shaft 21, an intermediate transmission shaft 23, a transition gear 24 and a second driving gear 25 installed on the intermediate transmission shaft 23, an output hollow shaft 26, The passive gear 27 installed on the output hollow shaft 26, wherein the box body 1 includes the upper and lower housings, the transition gear 24 meshes with the first driving gear 22, the driven gear 27 meshes with the second driving gear 25, the One end of the output hollow shaft 26 is provided with a grease nipple and a channel 261 for injecting butter, and an O-ring groove 262 is provided on the inner hole wall near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com