Heat pump industrial drying machine

A dryer and industrial technology, applied in the direction of dryers, drying, heat pumps, etc., can solve the problems of high cost of use, unstable working performance, low energy utilization rate, etc., and achieve the effect of convenient use and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

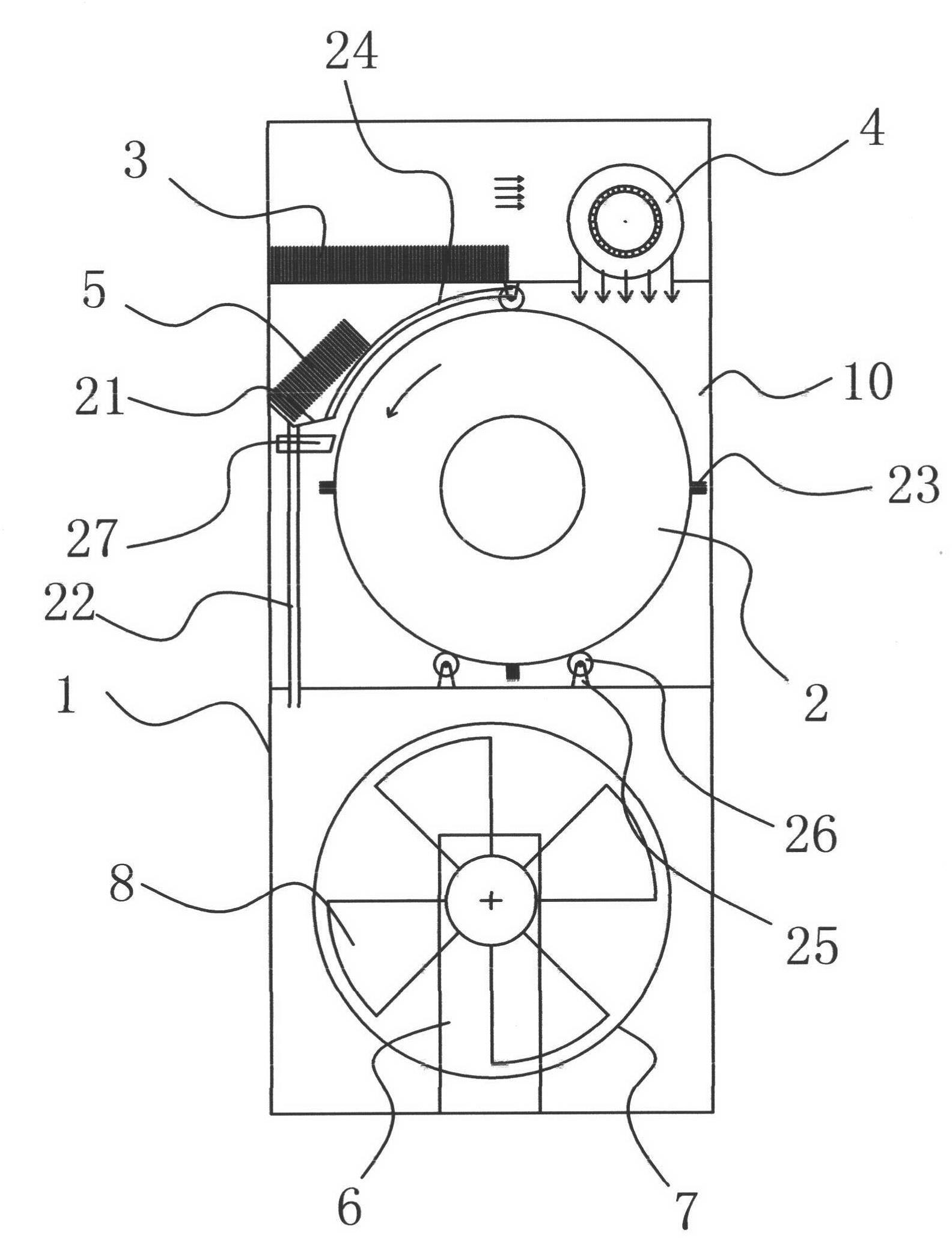

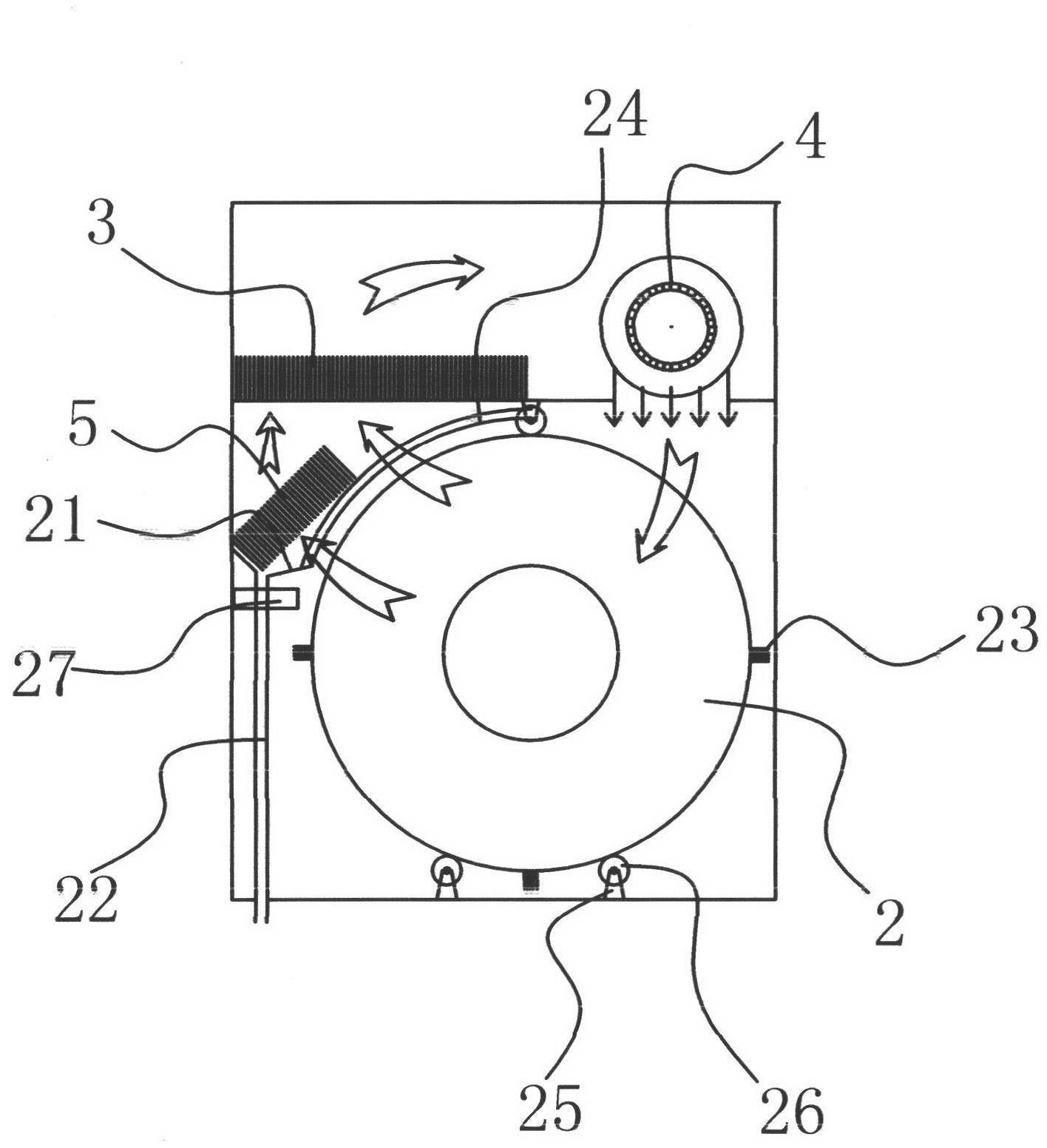

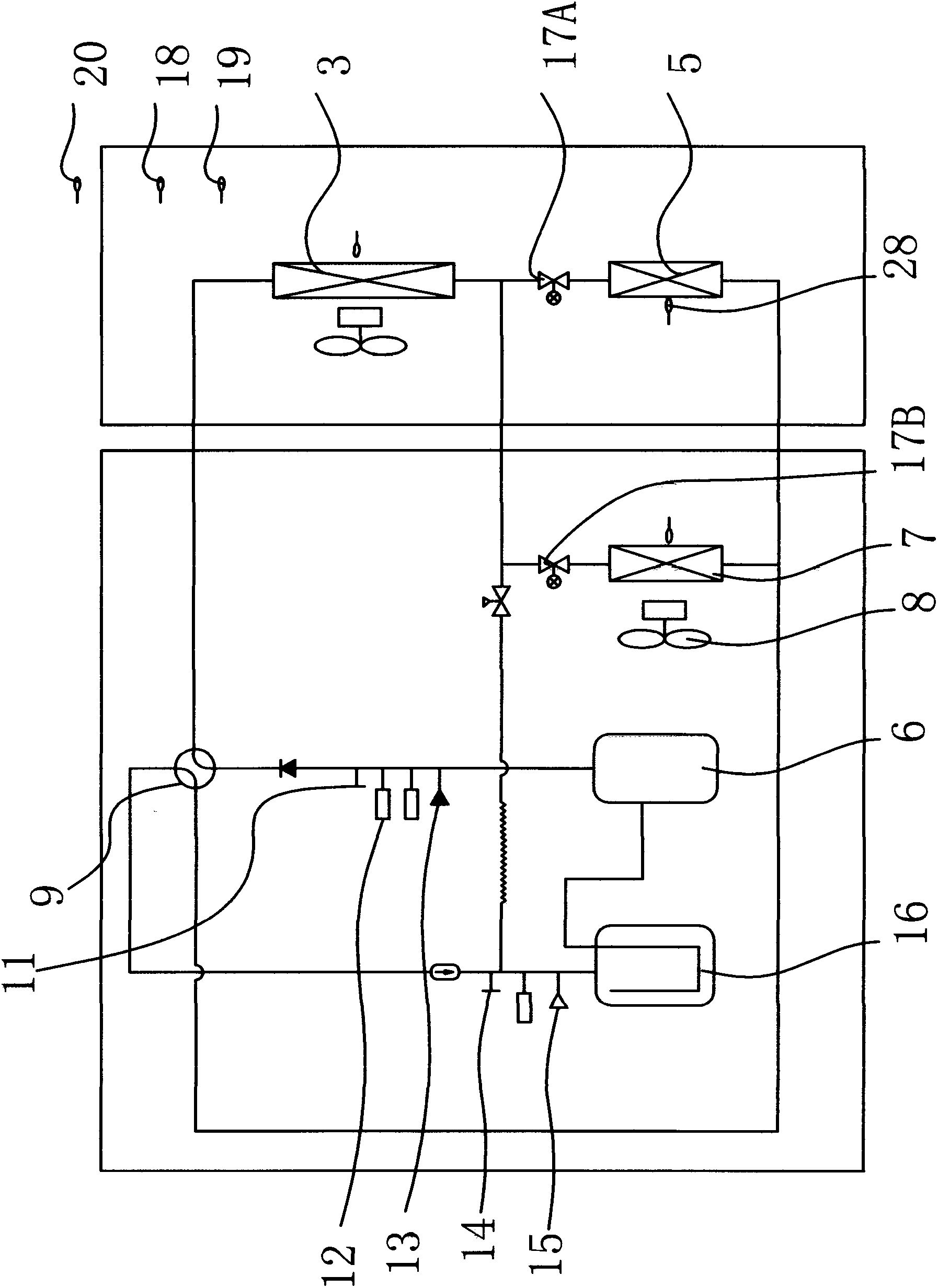

[0023] like figure 1 , 2 As shown in and 3, the heat pump industrial dryer includes a casing 1, and a sealed drying chamber 10 is arranged on the top of the casing 1. A cylindrical drum 2 is arranged inside the drying chamber 10, and the drum 2 is connected with a drum driving mechanism. The drying chamber 10 is provided with a condenser 3 which is located above the drum 2 and whose temperature is higher than the air temperature in the drying chamber 10. On one side of the condenser 3, a condenser 3 can be cooled and the hot air can be blown into the drum 2 to be heated. The circulation fan 4 on the heating and drying object. Below the condenser 3 is provided a dehumidifier 5 whose temperature is lower than the air temperature in the drying chamber 10, and below the dehumidifier 5 is provided a water collecting mechanism. The lower part of the box body 1 is provided with a heat pump system connected with the condenser 3 and the dehumidifier 5 . like figure 2 As mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com