Hopkinson bar active pressure confining device for stabilizing pressure

A Hopkinson pressure bar, active technology, used in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problem of increasing the size of the confining pressure device, increasing the difficulty of sealing, and limiting the size of the device. problems, to achieve the effect of small sealing difficulty, easy replacement and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

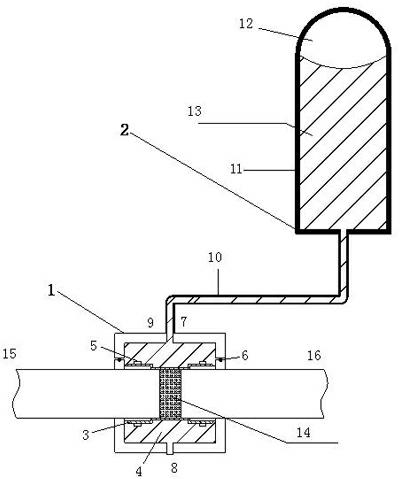

[0021] The specific embodiments of the present invention will be further elaborated below in conjunction with the accompanying drawings.

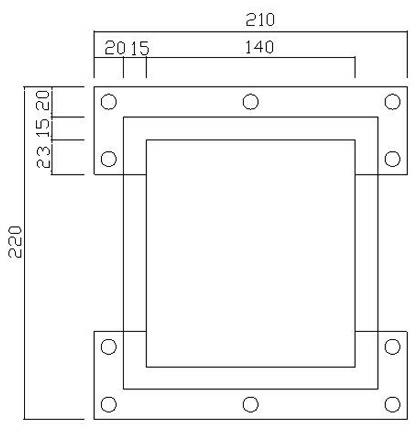

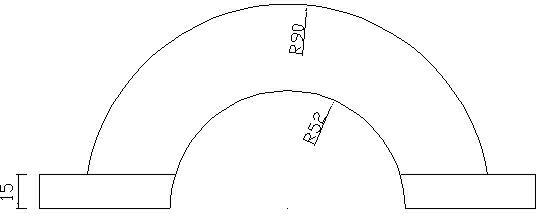

[0022] The invention includes an active confining pressure device 1 and a pressure stabilizing device 2 suitable for a 74mm Hopkinson bar. Confining pressure device 1 is composed of rubber interlayer 3, hydraulic oil chamber 4, snap ring 5, O-shaped rubber seal 6, etc.; The interface 7 on the active confining pressure device is connected with the pressure stabilizing device to form an integral sealed oil chamber. The hydraulic oil chamber is sealed by an O-shaped rubber seal, and the rubber interlayer is connected to the oil chamber through a snap ring to act as a sealed test piece. role. The incident rod 15, the test piece 14, and the transmission rod 16 also pass through the lower part. The oil outlet 9 and the oil inlet 8 are respectively located at the top of the upper and lower parts of the confining pressure device, and the interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com