Lifting method of submarine cable terminal landing platform

A submarine cable and platform technology, applied in the field of offshore oil engineering, can solve the problem of high daily cost, save man-hours, reduce operating vessel days, and quickly lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

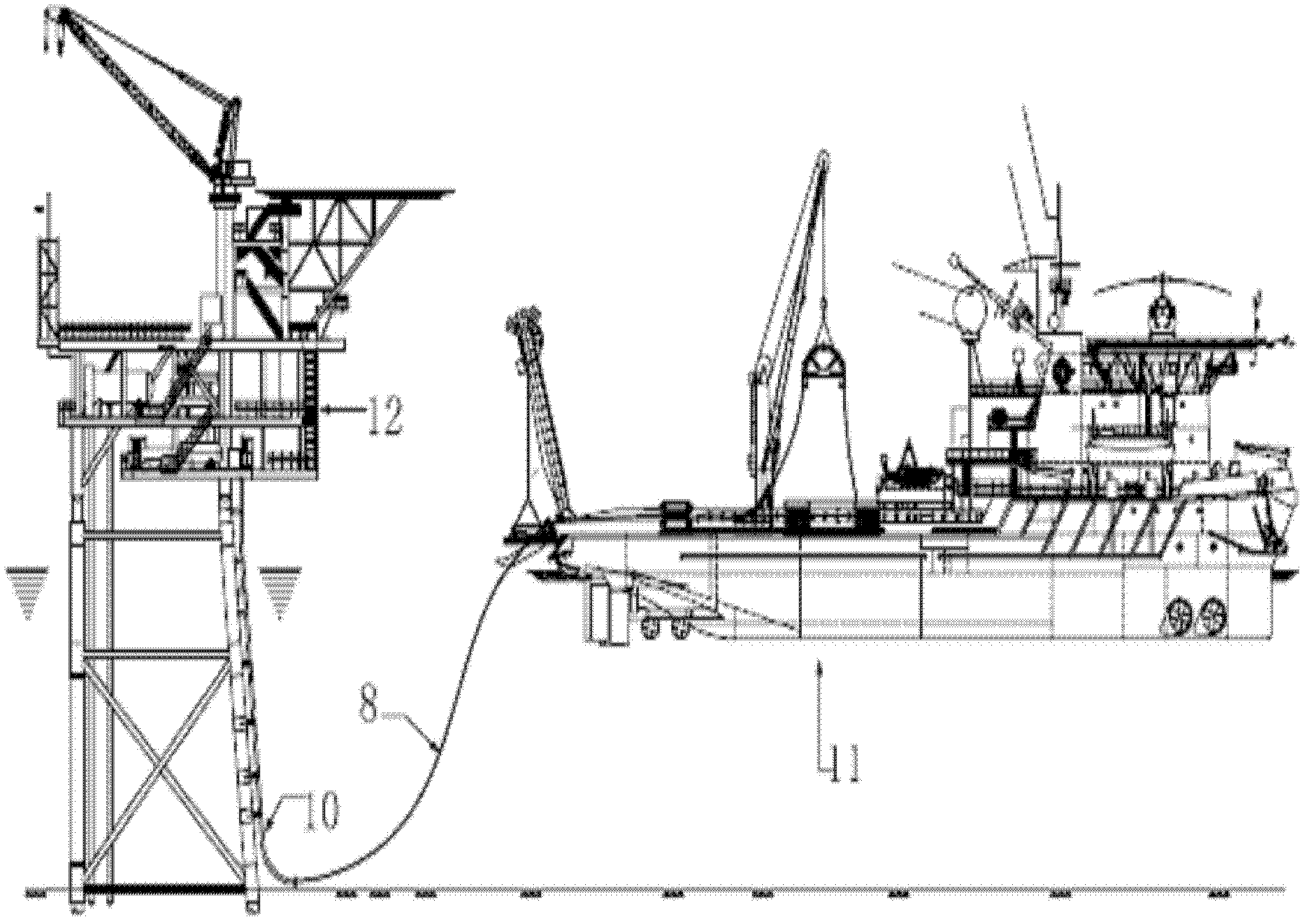

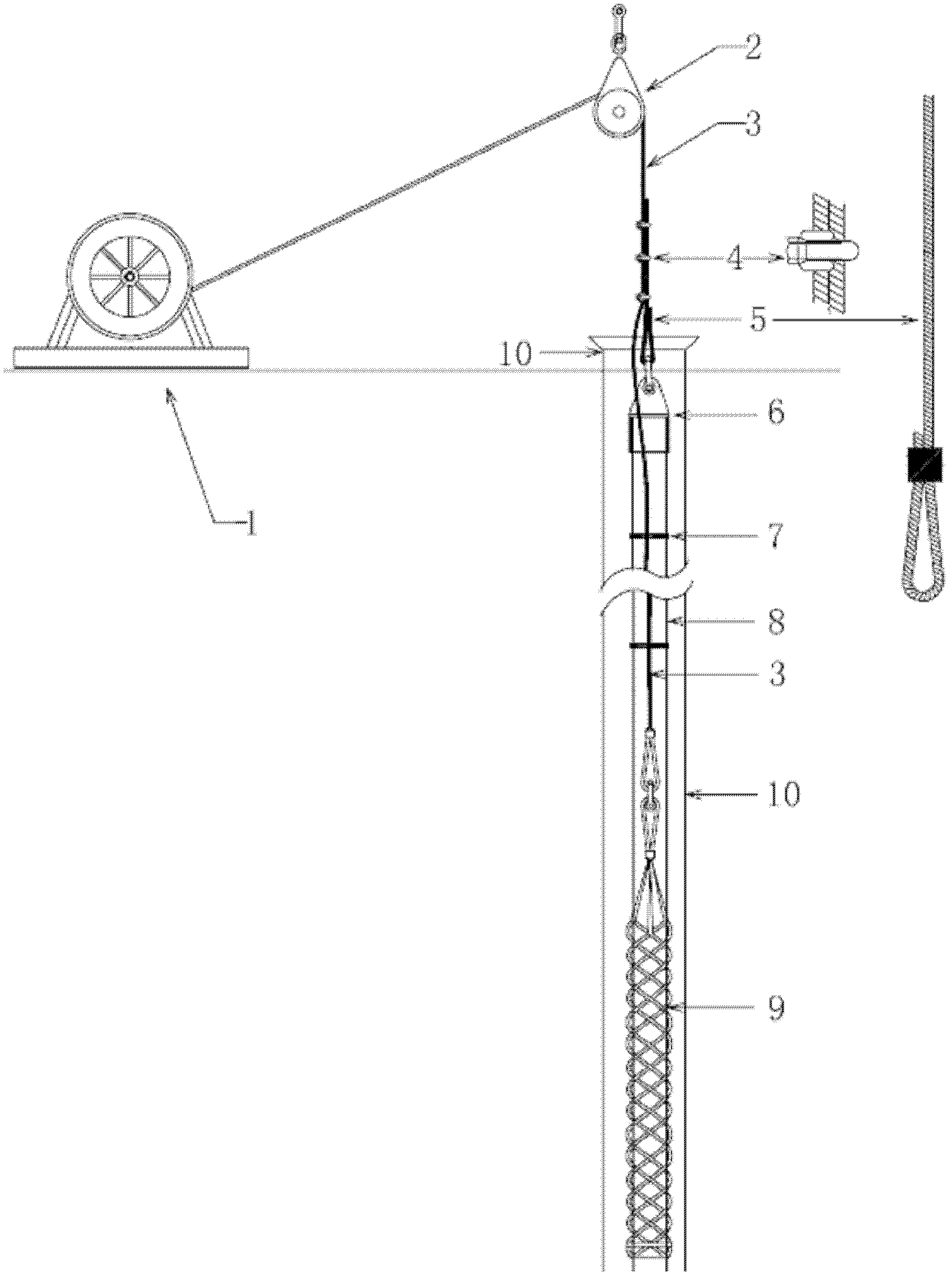

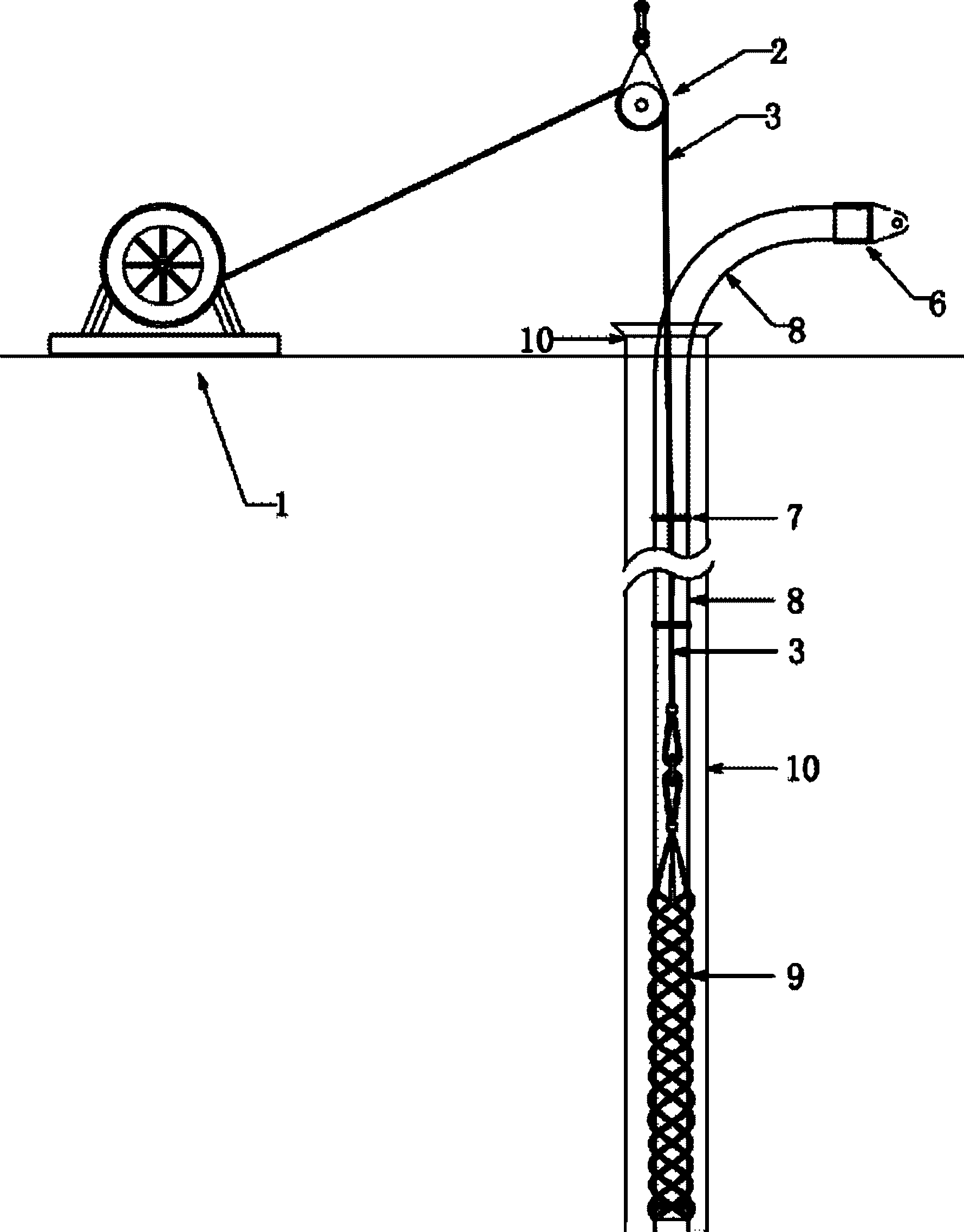

[0037] The winch 1 is pre-installed on the available space position on the production platform 12, and a pulley 2 is installed above the head of the submarine cable protection tube, and the steel wire rope 3 of the winch 1 is passed through the pulley 2 and connected with the pre-installed in the submarine cable protection tube. A lead rope is connected; The submarine cable protection tube in this embodiment is: a J-shaped tube 10 .

[0038] Such as figure 1 , figure 2 , image 3 Shown, the present invention adopts following steps:

[0039] The first step: start the winch on the cable-laying ship 11, and drag the steel wire rope 3 of the platform winch 1 to the deck of the cable-laying ship 11 by the guide rope pre-installed in the submarine cable protection tube, that is, the J-shaped pipe 10;

[0040] Second step: connect a Pipa head short rope on the submarine cable dragging head 6; The short rope of the present embodiment is: the same diameter specification with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com