Microencapsulated hardener for epoxy resin, masterbatch type hardener composition for epoxy resin, one-pack epoxy resin composition, and processed article

A technology for epoxy resin, epoxy resin, applied in the direction of epoxy resin glue, plastic/resin/wax insulator, adhesive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

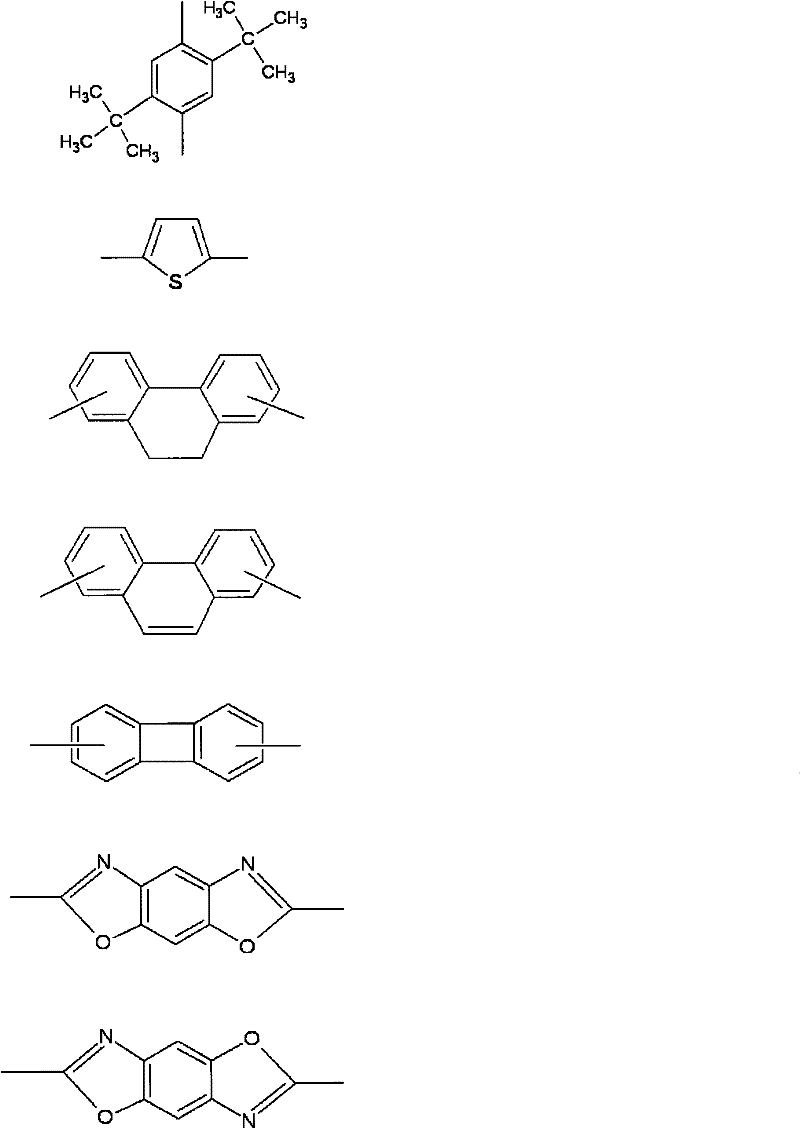

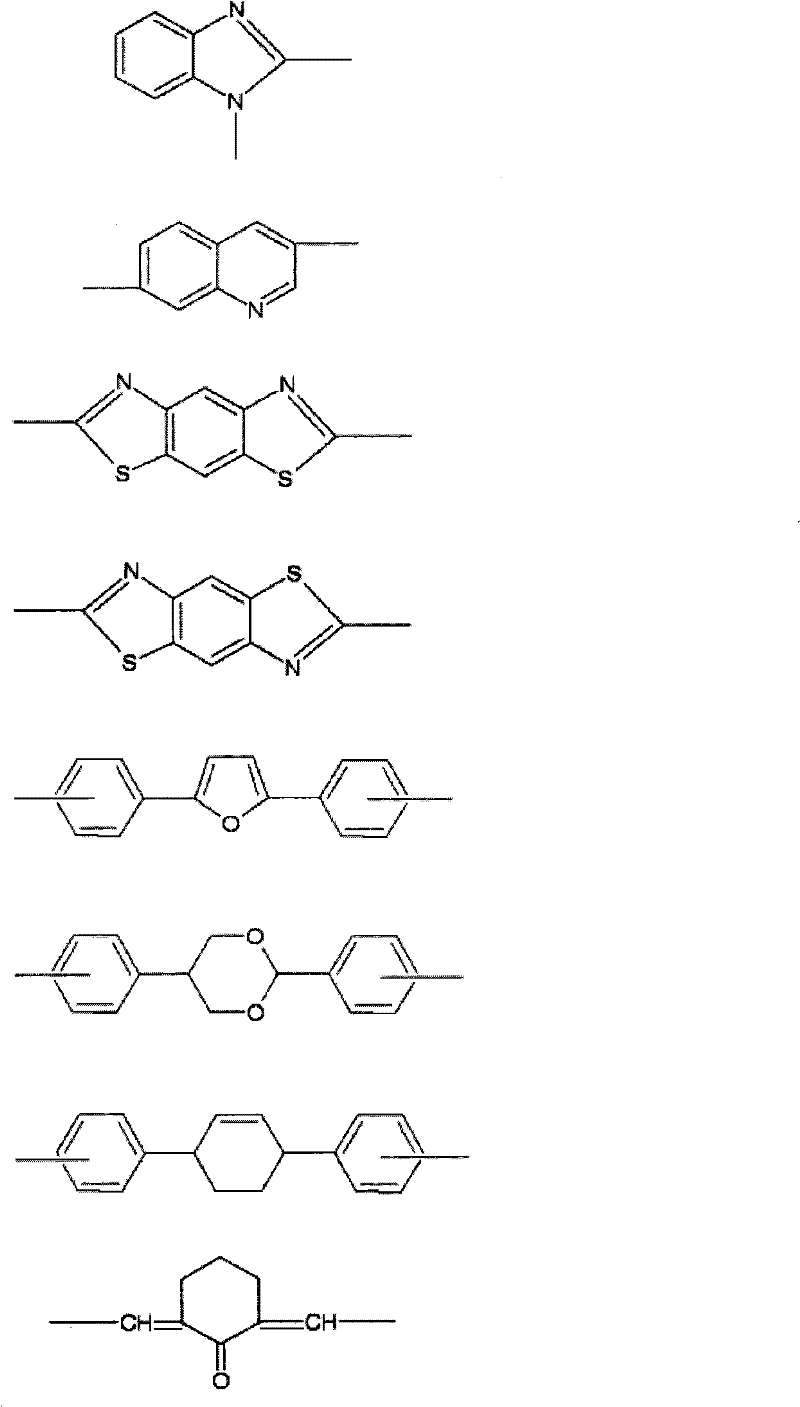

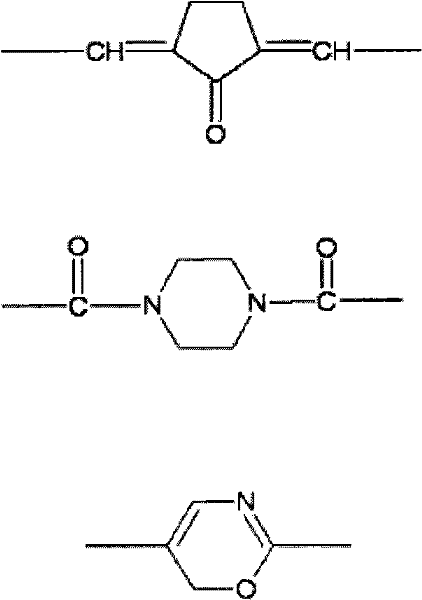

Method used

Image

Examples

Embodiment

[0389] This invention is demonstrated based on an Example.

[0390] In addition, in the following physical property measurements, evaluations were ◎, ○, △, ×, and ××, but in the specification of the present application, as long as ◎, ○, and △ were evaluated, they were evaluated as sufficient values for obtaining the effects of the present application.

manufacture example 1-1~1-10

[0392] In the solvent shown in Table 2, under the conditions of reaction solution concentration and reaction temperature shown in Table 2, the epoxy resin (e1) and the hydrocarbon group having more than one primary amino group and / or aliphatic or alicyclic Or secondary amino amine compound reaction. Thereafter, the solvent was distilled off under reduced pressure to obtain amine adducts or bulk curing agents for epoxy resins h-1 to h-10 mainly composed of amine adducts. In addition, the evaluation result of the hardening|curing agent for epoxy resins h-1-h-10 which obtained block shape is collectively described in Table 2.

[0393] In addition, unless otherwise specified, "triethylenetetramine" and "tetraethylenepentamine" described in the tables of the examples are reagents manufactured by Wako Pure Chemical Industries, and each is ethyleneamine. mixture. As these charging amounts at the time of reaction, the equivalent in terms of triethylenetetramine and tetraethylenepent...

manufacture example 2-1

[0401] Add tert-butyl hydroquinone 166g (1 mole), epichlorohydrin 1850g (20 moles), glycidol 296g (4 moles), tetramethyl chloride Ammonium 0.55g, addition reaction under heating and reflux for 2 hours. Next, the content was cooled to 60° C., a water removal device was installed, and 183 g (2.2 mol) of 48.5% sodium hydroxide was added thereto. The generated water was continuously azeotropically removed under conditions of a reaction temperature of 55-60° C. and a reduced pressure of 100-150 mmHg, and a ring-closure reaction was carried out while returning the epichlorohydrin layer in the distillate to the reaction system. The point at which generated water reached 56.5 ml was defined as the end point of the reaction. Thereafter, vacuum filtration and water washing were repeated, and residual epichlorohydrin was recovered by vacuum distillation to obtain a crude epoxy resin.

[0402] The obtained crude epoxy resin was subjected to repeated vacuum distillation to obtain highly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com