Large-diameter die with requirements on positions of inner ring and outer ring and processing method thereof

A processing method and technology for inner and outer rings, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing efficiency and low processing cost, and achieve high processing efficiency, low processing cost and reduced mold investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

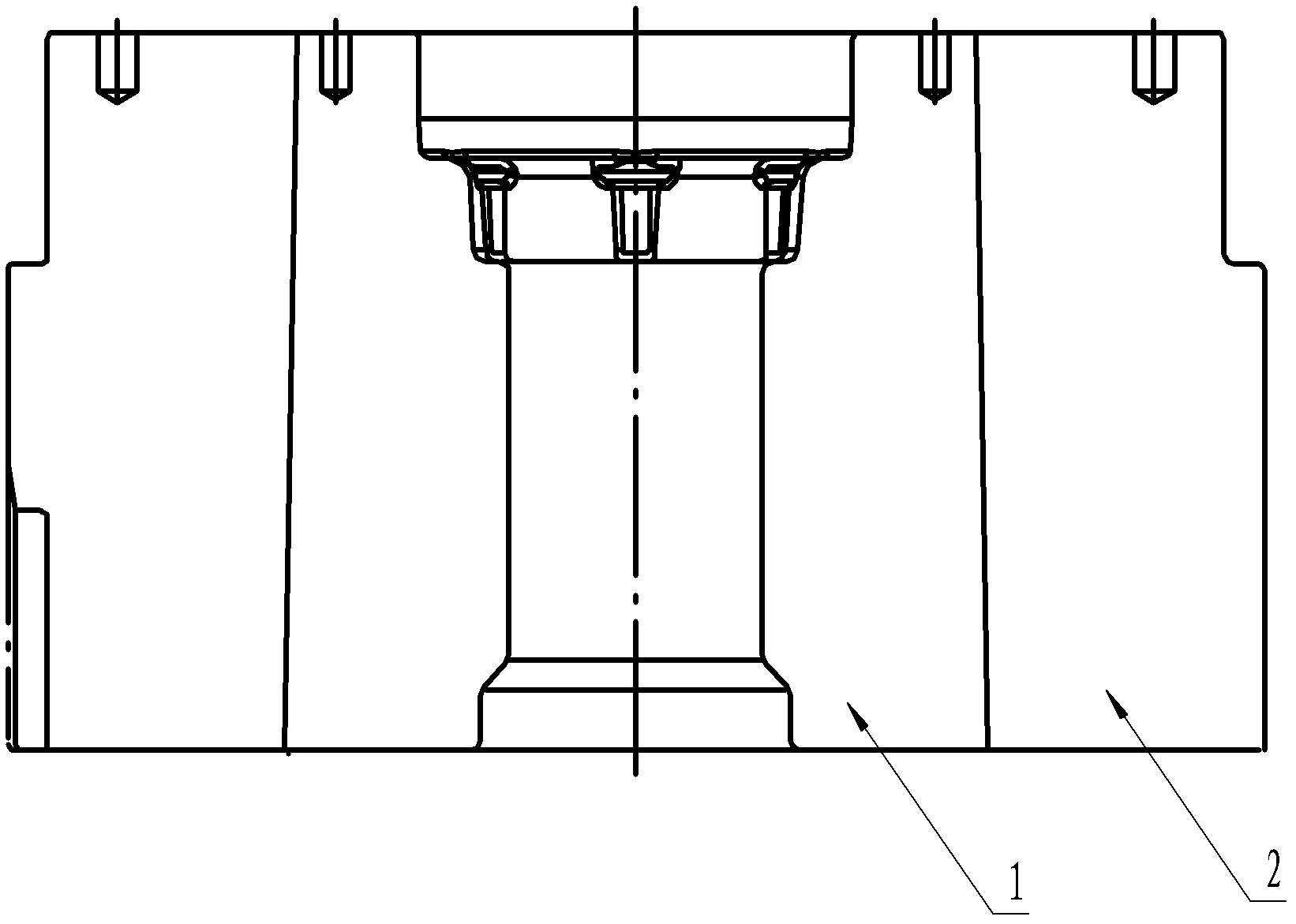

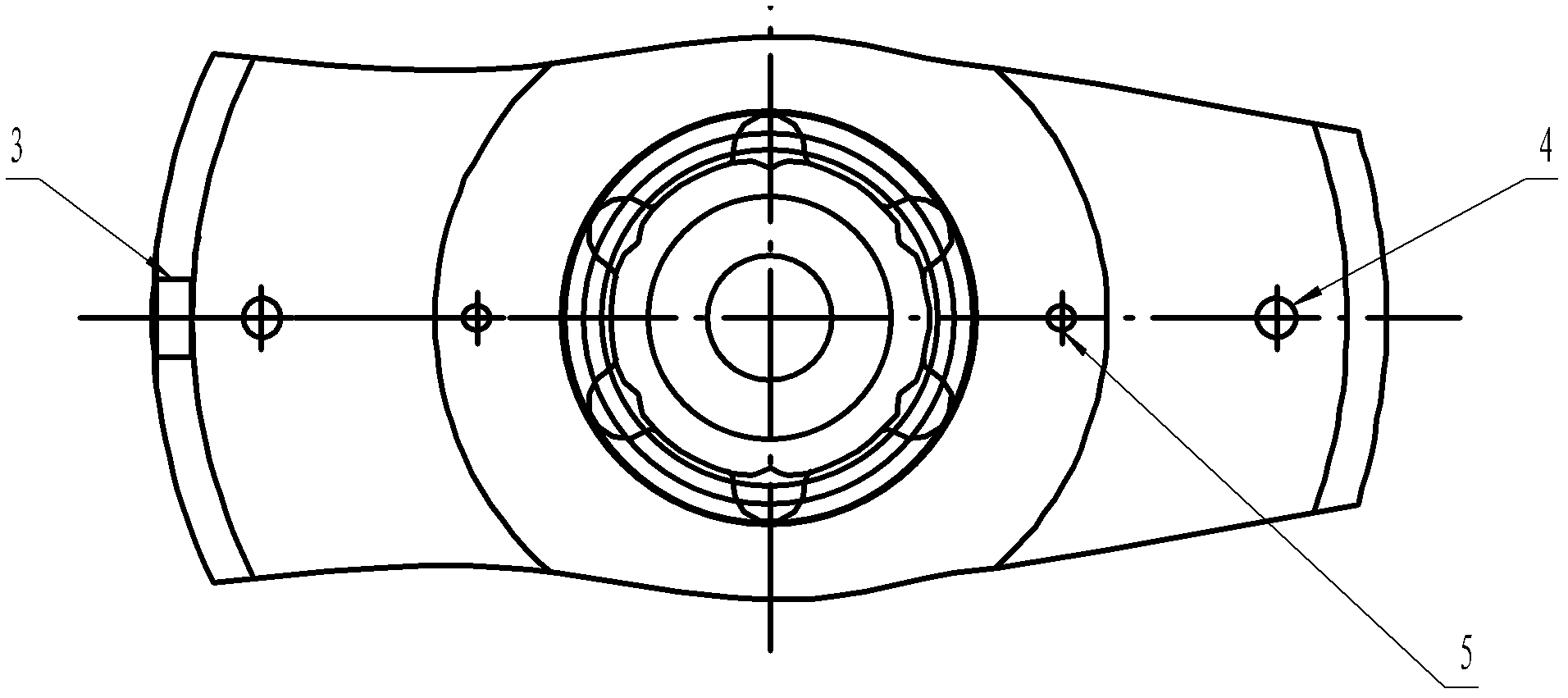

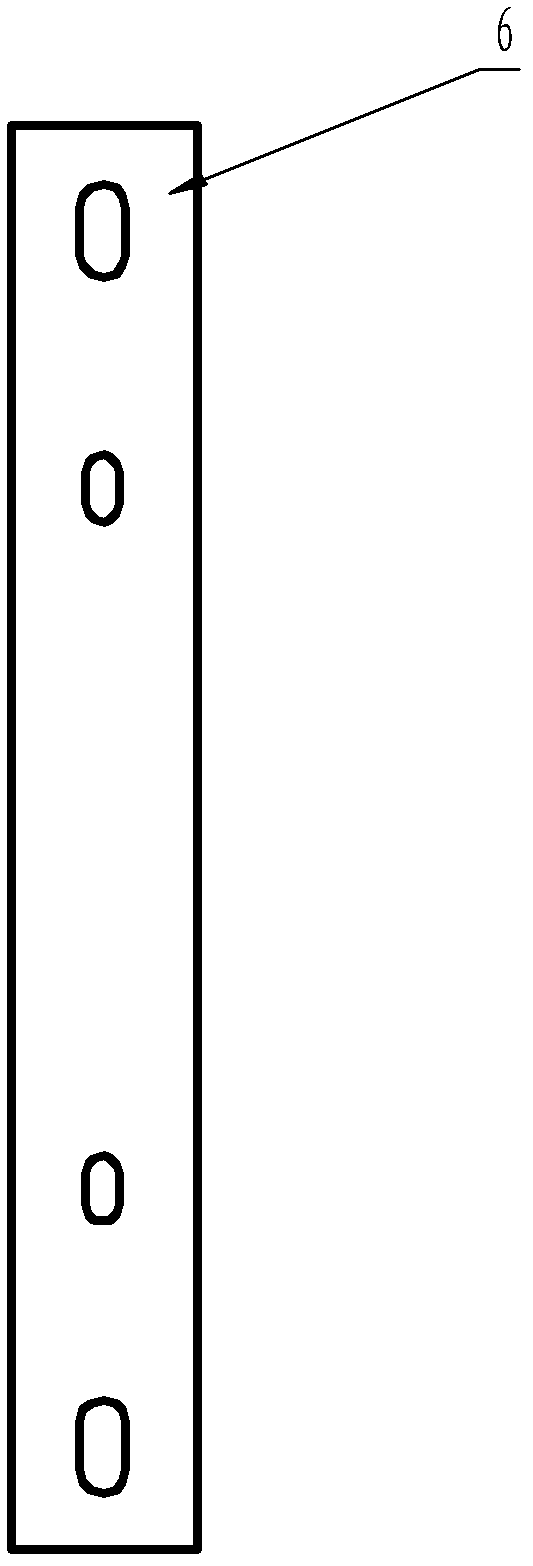

[0016] The present invention will be further described below in conjunction with the accompanying drawings, as shown in the figure, wherein: 1. inner ring, 2. outer ring, 3. keyway, 4. outer ring positioning pin hole, 5. inner ring positioning pin hole, 6. fixing Pressure plate, 7. Pin A, 8. Pin B, 9. Press-fit surface.

[0017] Such as figure 1 , figure 2 Shown is a mold with position requirements for the inner and outer rings of large diameter. The mold includes an inner ring 1, an outer ring 2, and a keyway 3. The keyway ring is opened on the periphery of the outer ring. The positioning pin holes 4 of the outer ring and the positioning pin holes 5 of the inner ring are required to be consistent in position, and the axes of the positioning pin holes of the inner and outer rings are related to the datum on the same central plane. The datum is the centerline of the keyway.

[0018] The mold processing method is to separately process the outer ring and the inner ring and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com