Polishing machine

A polishing machine, polishing pad technology, applied in the direction of grinding machines, grinding/polishing equipment, portable grinding machines, etc. The effect of low work cost, reduced friction injury, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

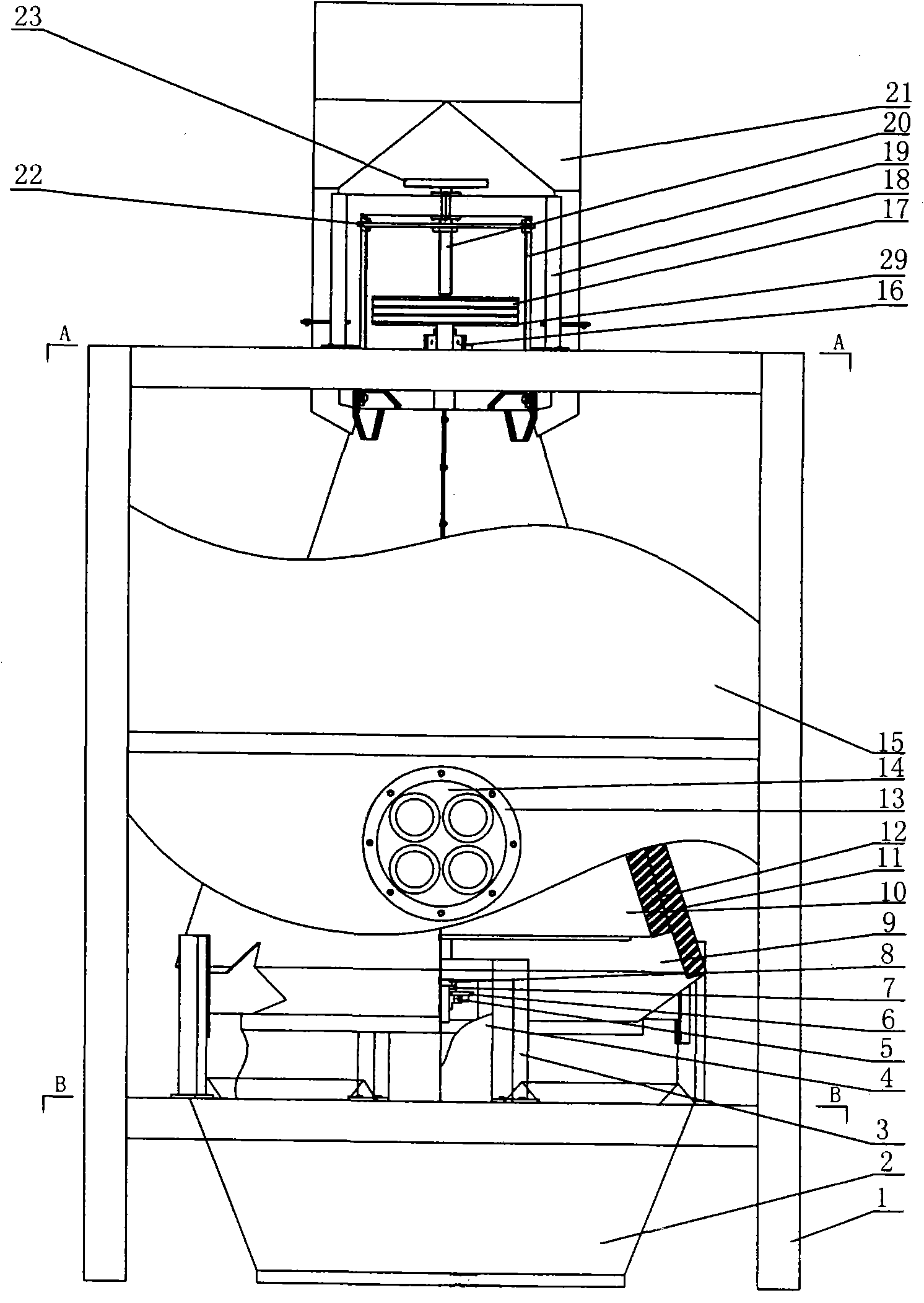

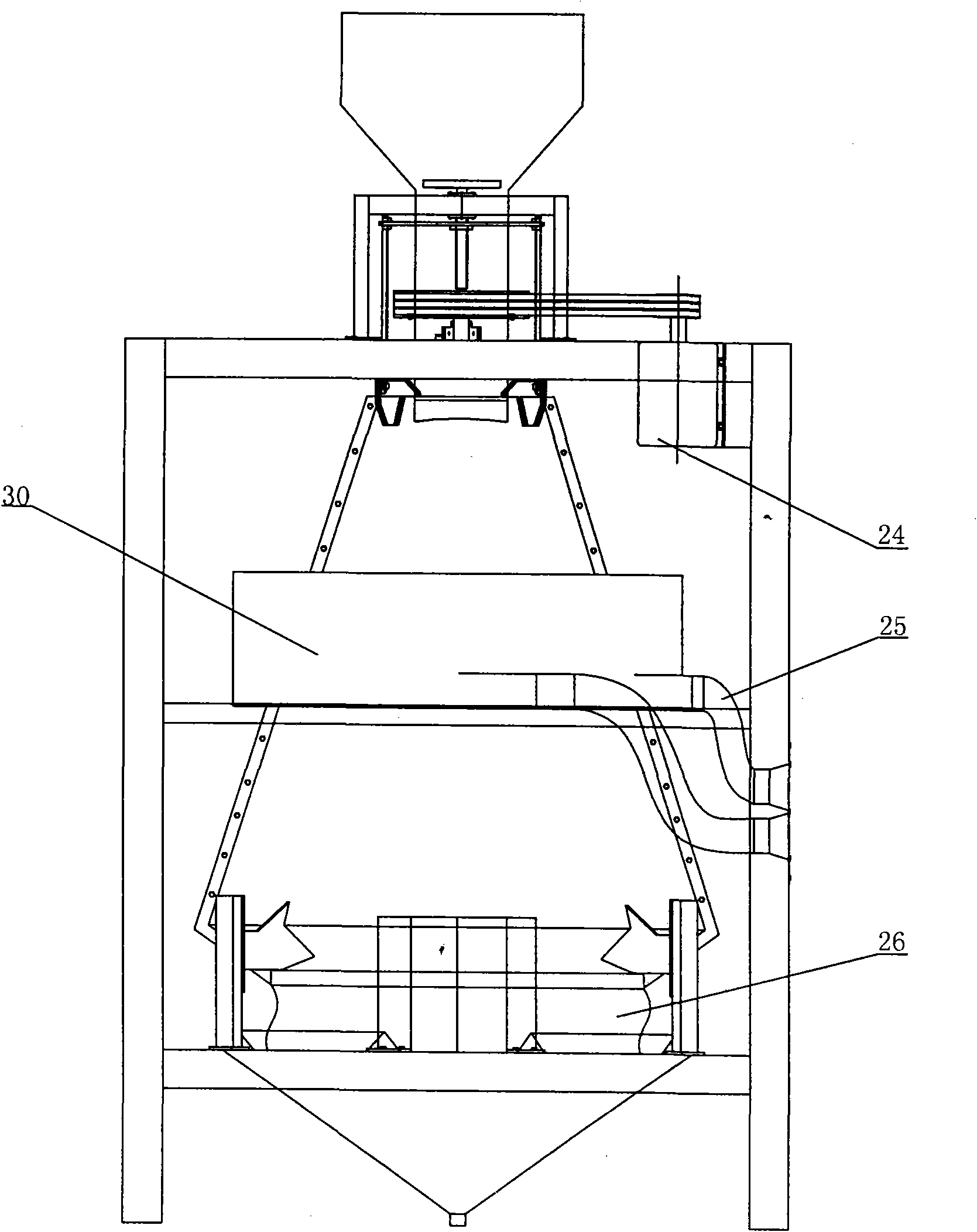

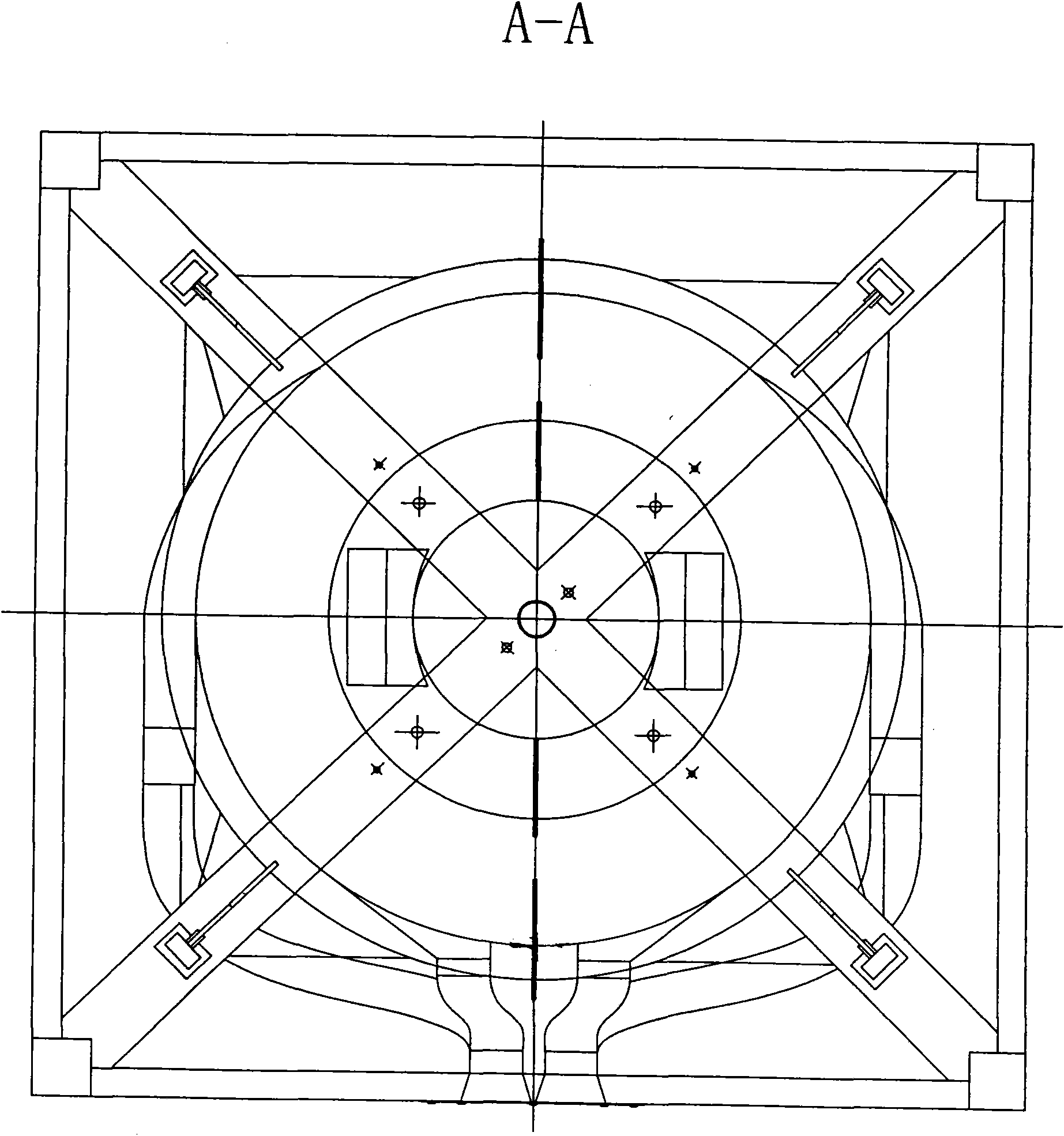

[0031] Such as Figure 1 to Figure 6 As shown, the polishing machine includes a frame 1, a lower hopper 2, a support frame 3, a baffle plate 4, a rolling ball bearing 5, a bearing seat 6, a thrust bearing 7, a transmission shaft 8, a polishing sleeve, an outer casing polishing pad 11, Inner sleeve polishing pad 12, vent flange 13, vent panel 14, cover plate 15, rolling ball bearing 16, V-belt 17, adjustment frame 18, screw 19, screw 20, hopper 21, adjustment plate 22, hand Wheel 23, motor 24, exhaust pipe 25, screen 26, flange interface 27, small round hole 28, V-belt pulley 29, exhaust fan 30, motor 24 and lower hopper 2 are installed on the frame 1, and the sleeve is polished It includes an outer polishing sleeve 9 and an inner polishing sleeve 10, the inner polishing sleeve 10 is welded on the transmission shaft 8, the outer polishing sleeve 9 is set on the outside of the inner polishing sleeve 10, and the outer polishing sleeve 9 The inside is inlaid with a cowhide leathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com