Ethylene-vinyl alcohol (EVOH) copolymer packaging material for tomato products

A technology of vinyl alcohol copolymers and tomato products, which is applied in packaging, wrapping paper, hollow objects, etc., can solve the problems of undiscovered improvement technology disclosure, and achieve the effect of ensuring tomato food quality, safe storage, and taking into account manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

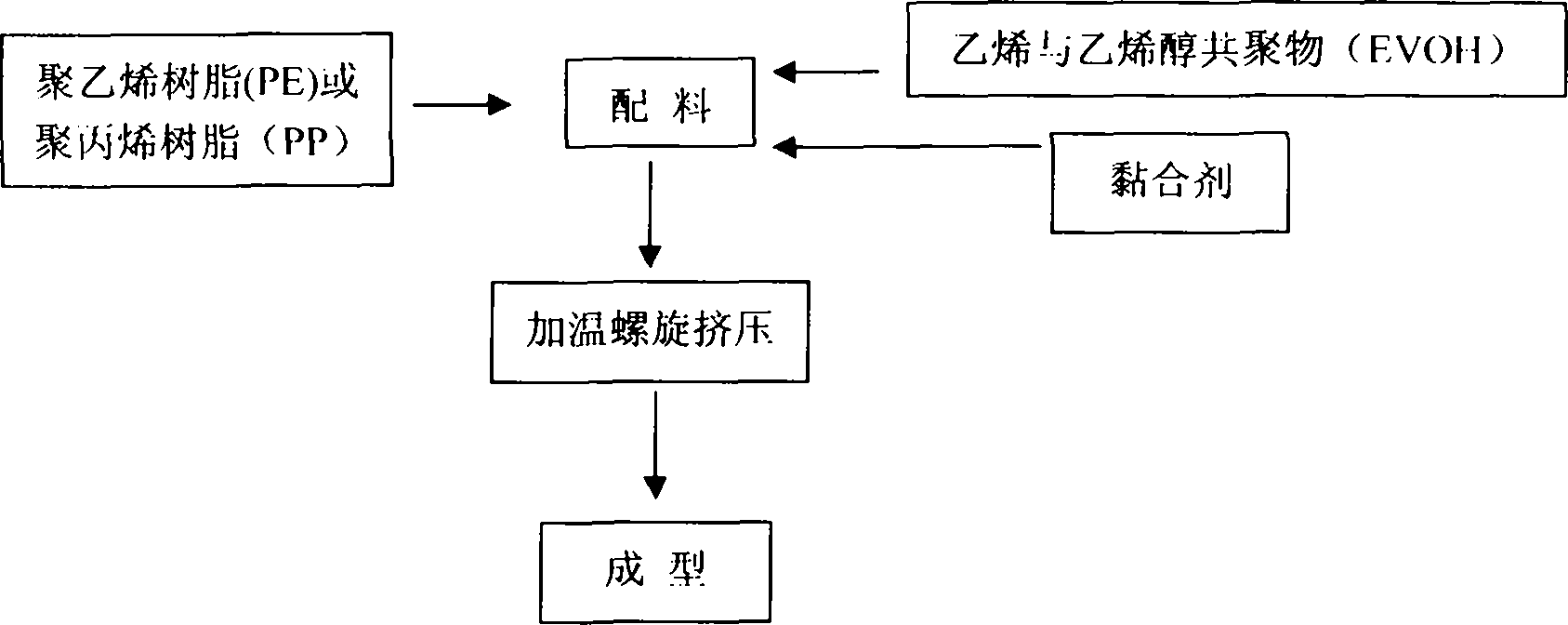

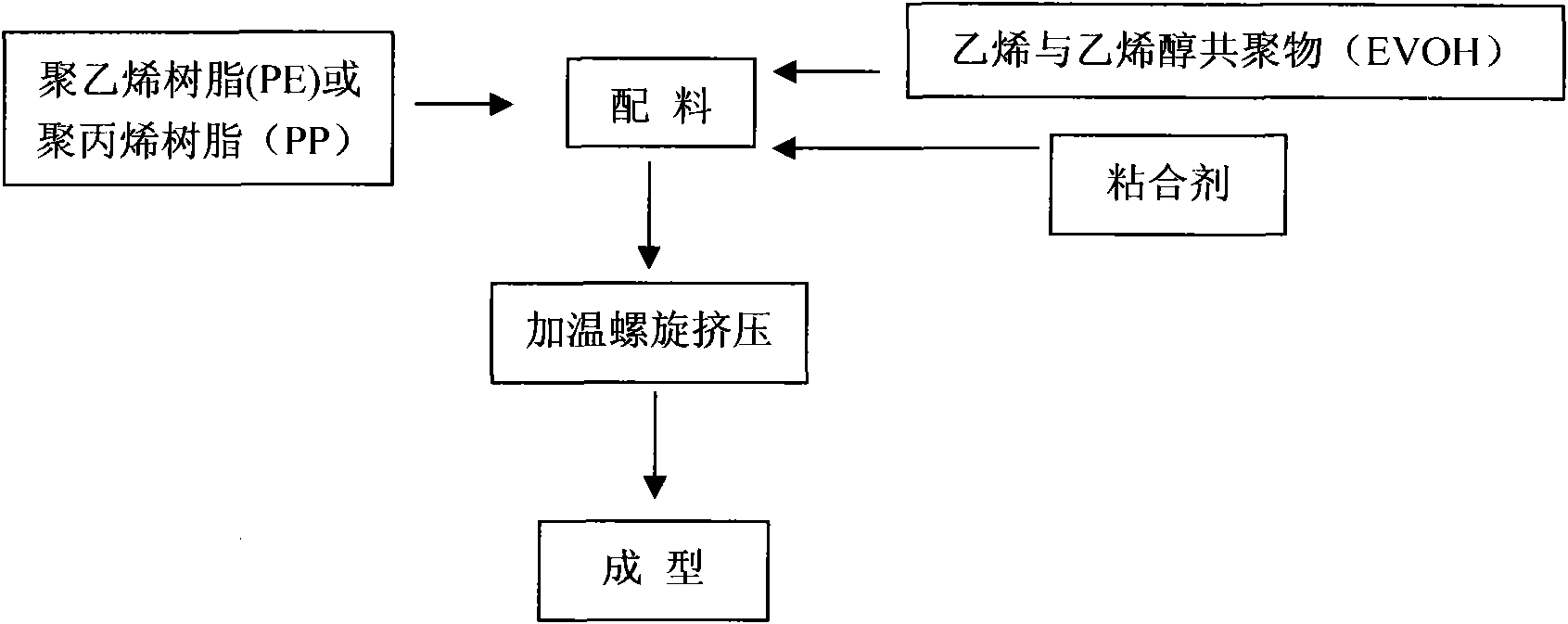

[0008] Embodiment 1: In parts by weight, with 83%-89% of polyethylene resin or polypropylene resin and 3%-7% of ethylene and vinyl alcohol copolymer, respectively uniformly stirred and kept dry; the aforementioned raw materials after homogenization and 8 %-10% binders are respectively added to the molding machine trough to raise the temperature. After the temperature is 170-200°C, the two sides of the ethylene-vinyl alcohol copolymer are used as the intermediate material to compound polyethylene resin or polypropylene resin with the binder. Five layers of composite.

[0009] The binder is an acid-modified polyolefin.

[0010] When adopting the embodiment of the present invention to make packaging bottles, the molding process is to form the material tube by screw extrusion, and the material tube of the blow molding machine is blown into a molded bottle shape under a pressure of 0.7 MPa, and the mold is cooled to 30-20 °C by circulating water. Cool to 45-35°C, remove the leftov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com