Electrochemical degradation device in modularized serial connection

An electrochemical and modular technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor effects, achieve flexible disassembly, and facilitate replacement and maintenance.

Active Publication Date: 2012-02-01

ZHEJIANG UNIV

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Especially the wastewater produced by chemical industry, dyestuff, pharmaceutical, printing and dyeing, coking and other industries, because the molecular structure of the organic pollutants contained is relatively stable, the conventional physical chemical method and biochemical method are used for treatment, and the effect is very poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

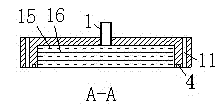

[0030] Embodiment: with reticular Ti / PbO 2 It is the anode, the stainless steel plate is the cathode, the distance between the cathode and the anode is 2mm, and the COD of the chemical oxygen demand is about 200-400 mg / L. After being treated by the system shown in the present invention, the effluent COD can be reduced to below 50 mg / L. , energy consumption is 5-10 kWh / m 3 waste water.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

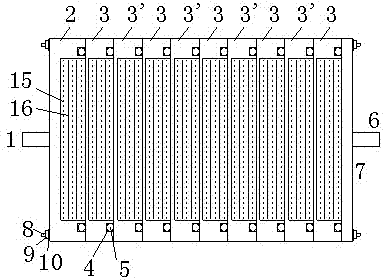

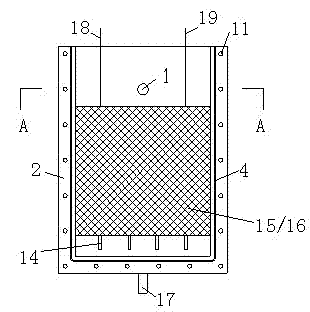

The invention discloses an electrochemical degradation device in modularized serial connection. Grooves are respectively arranged on the side surfaces of end modules, N type A middle modules and (N-1) type B middle modules, lower and upper water pass small holes are respectively arranged on the two types of the middle modules, the grooves arranged on the end modules are communicated with a water inlet pipe, after the two types of middle modules are ranged at intervals, the end modules and end plates are arranged at both sides of the middle modules, then, screw rods and screw nuts are used for fastening, all modules are sequentially communicated through the lower water pass small holes or the upper water pass small holes, an electrode group with alternately ranged anodes and cathodes is respectively arranged in each module, the anodes and the cathodes are respectively and mutually connected in the same electrode group, the anodes in the end modules are connected with a positive electrode of a power supply, the cathodes in the type A middle modules next to the end plates are connected with a negative electrode of the power supply, and water discharge pipes are respectively arranged at the bottoms of the modules. The serial connection grade number of the electrochemical degradation device can be freely regulated according to requirements, and the modules in the same dimension are utilized and can be assembled into the degradation device with different treatment capabilities. The electrochemical degradation device can be used for the electrochemical degradation treatment on the industrial waste water.

Description

technical field [0001] The invention relates to an electrochemical degradation device, in particular to a modular series electrochemical degradation device for industrial waste water treatment. Background technique [0002] With the rapid development of industry, the number and types of organic pollutants entering water through various channels have increased sharply, causing serious pollution to the water environment and directly threatening human health. Especially the wastewater produced by chemical industry, dyestuff, pharmaceutical, printing and dyeing, coking and other industries, because the molecular structure of the organic pollutants contained is relatively stable, the effect of conventional physical chemical and biochemical methods is very poor. Electrochemical degradation is a new wastewater treatment technology that relies on electrolysis to generate strong oxidants to oxidize various pollutants. Compared with conventional physicochemical and biochemical method...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/461

Inventor 陈雪明

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com