Removable hanging pile bracket for construction of hanging pile of steel casing of cofferdam

A steel casing, detachable technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of time consumption, impact on construction period, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

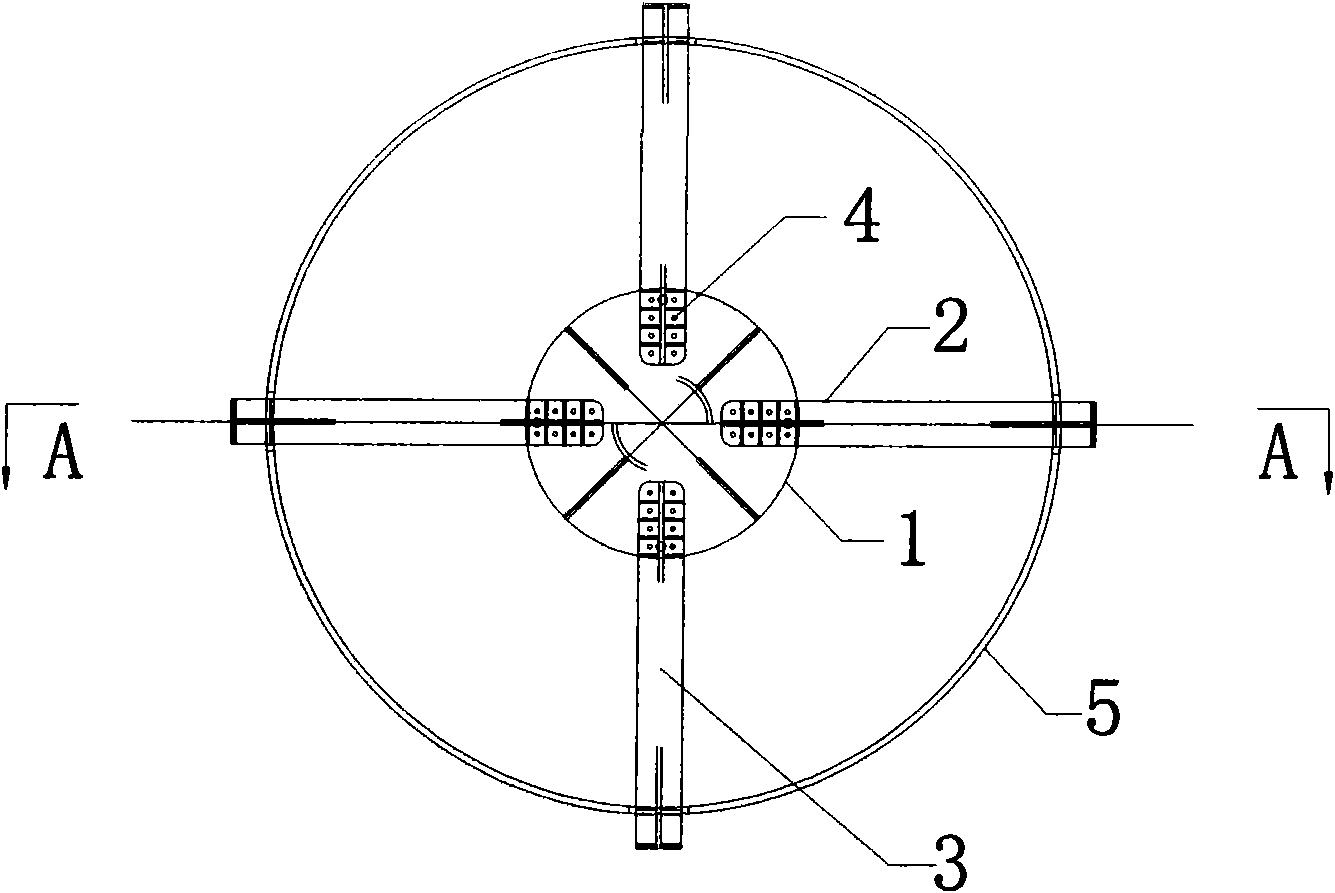

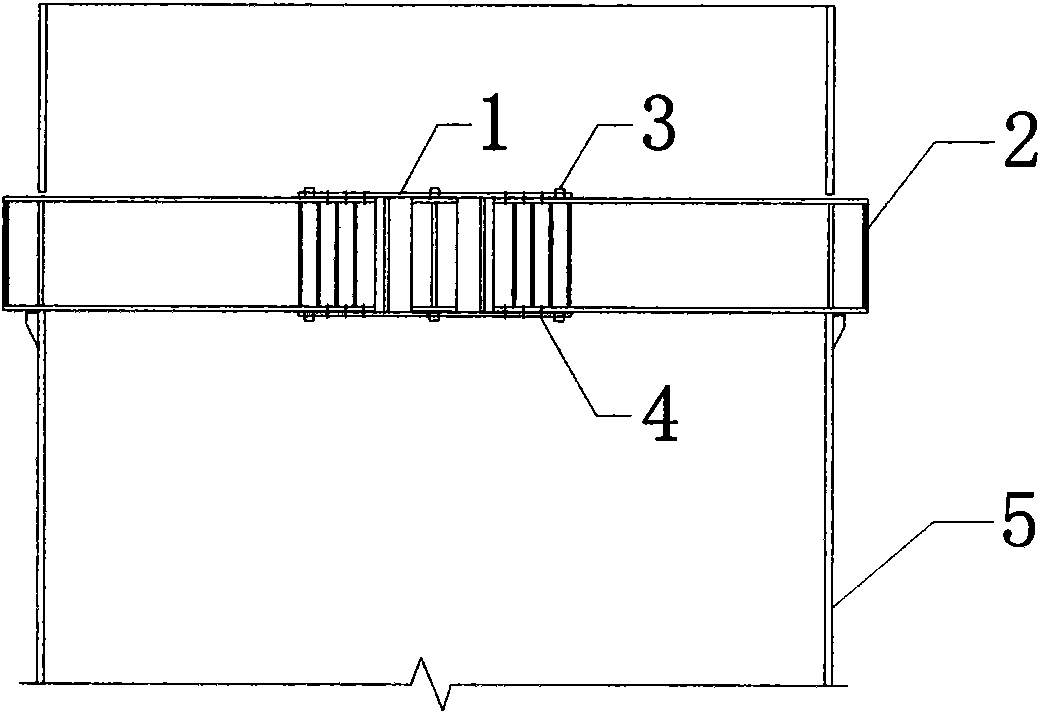

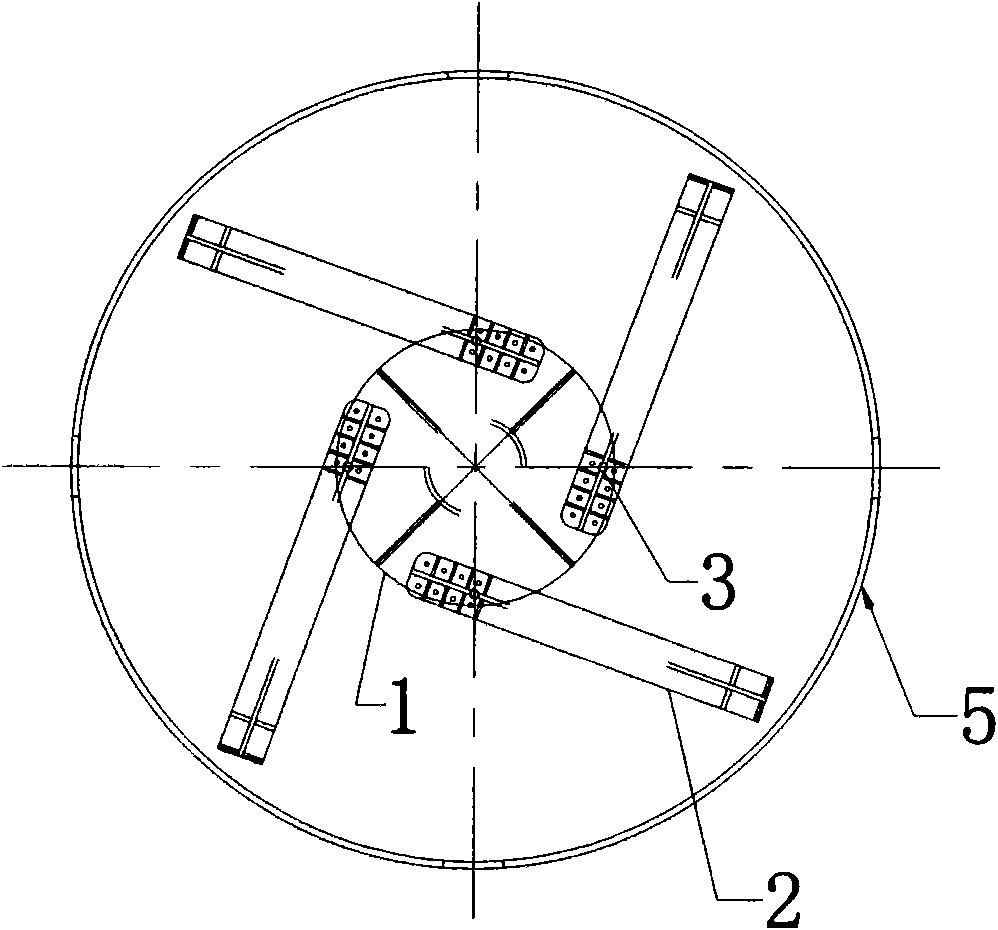

[0017] Such as figure 1 As shown, the present invention includes a central disk 1 and a plurality of legs 2, the central disk includes a central sleeve and upper and lower end plates welded on the upper and lower outer peripheral surfaces of the central sleeve, and the upper and lower end plates are respectively There are multiple sets of bolt mounting holes, and the multiple sets of bolt mounting holes are respectively arranged uniformly along the circumference of the center plate. The multiple legs 2 are respectively provided with through holes corresponding to the multiple sets of bolt mounting holes. The multiple legs 2 are respectively arranged along the The central disk 1 is evenly distributed in the circumferential direction between the upper and lower end plates and is respectively hinged to the upper and lower end plates through pin shafts 3 .

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com