Sealing type test device and method applicable to various types of oil pumps

A test device and test method technology, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve problems such as environmental pollution, small pressure adjustment range, and oil pump inlet pressure fluctuations, and achieve true measurement and test data. Accurate, avoid frequent startup, and eliminate the effect of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

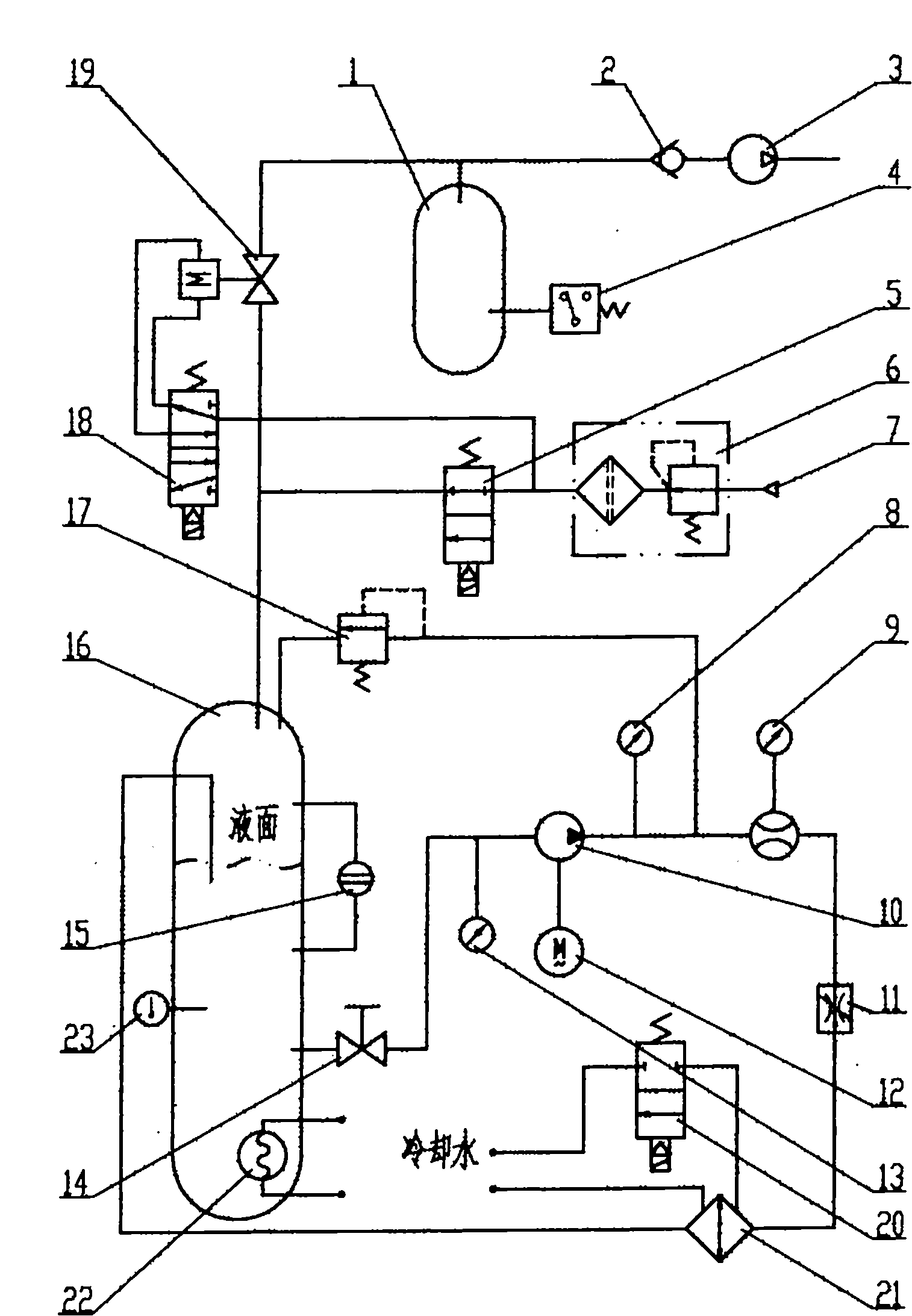

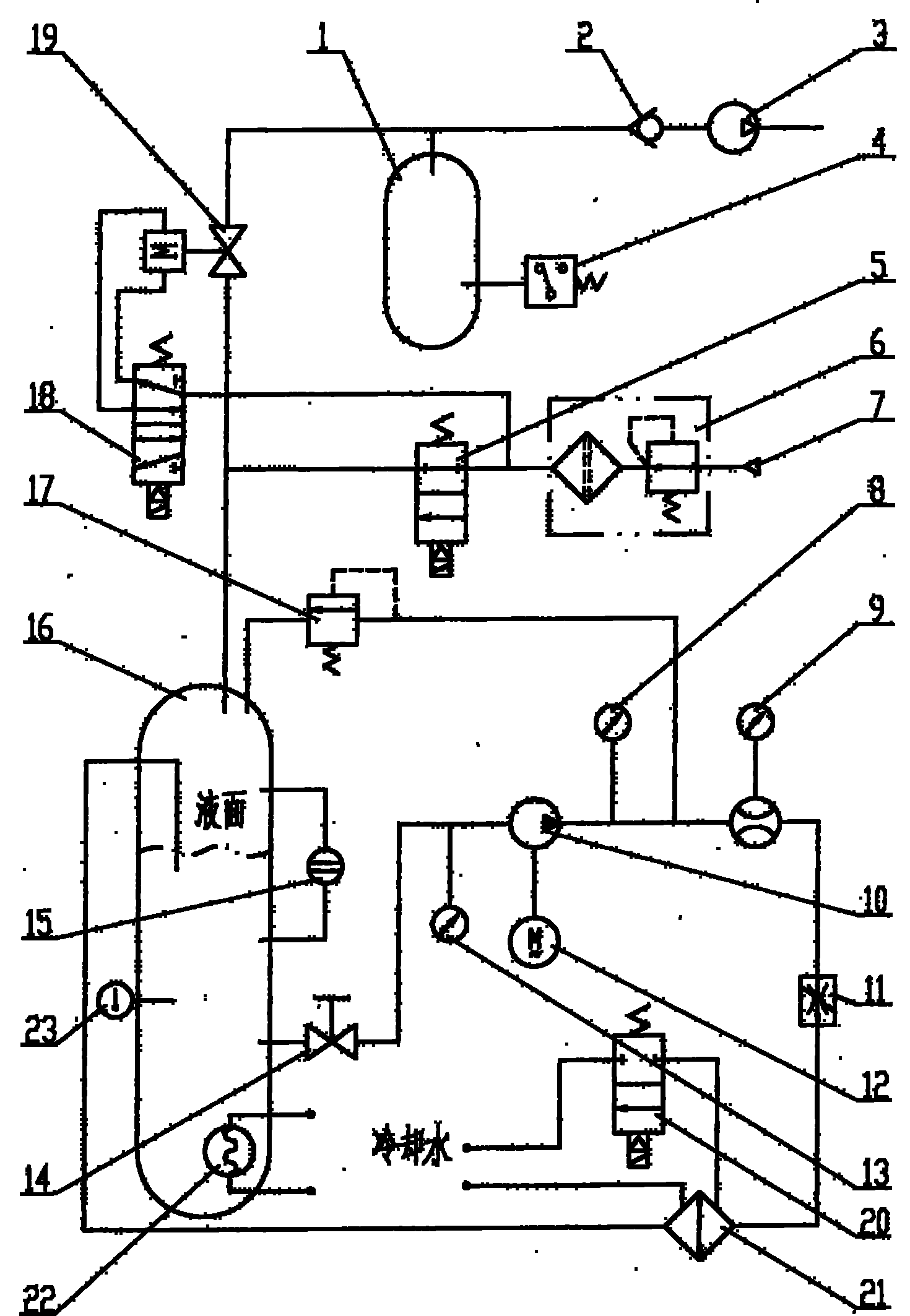

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] A closed test method suitable for various types of oil pumps, the method includes performing a cavitation test on the oil test pump, or performing a performance test. When the oil test pump is subjected to a cavitation test, the specific steps are:

[0027] Step 1. According to the working point of the oil pump, set the inlet pressure value G of the oil pump to be tested s The initial value of , and the step size of gradually decreasing the Gs value;

[0028] Step 2. Set each step G through the visual interface of the monitoring software in the upper computer s The upper and lower limits of ;

[0029] The inlet pressure value G of the oil test pump is treated by the computer control system s Real-time automatic measurement and control are carried out. When the inlet pressure value is greater than the upper limit value, the gas above the liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com