Stainless steel muffler and manufacturing process thereof

A manufacturing process, stainless steel technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of easy rust and corrosion manufacturing process, easy pollution of the environment, high cost of mufflers, etc., to reduce anti-rust spraying Disposal, improvement of environmental protection, and effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

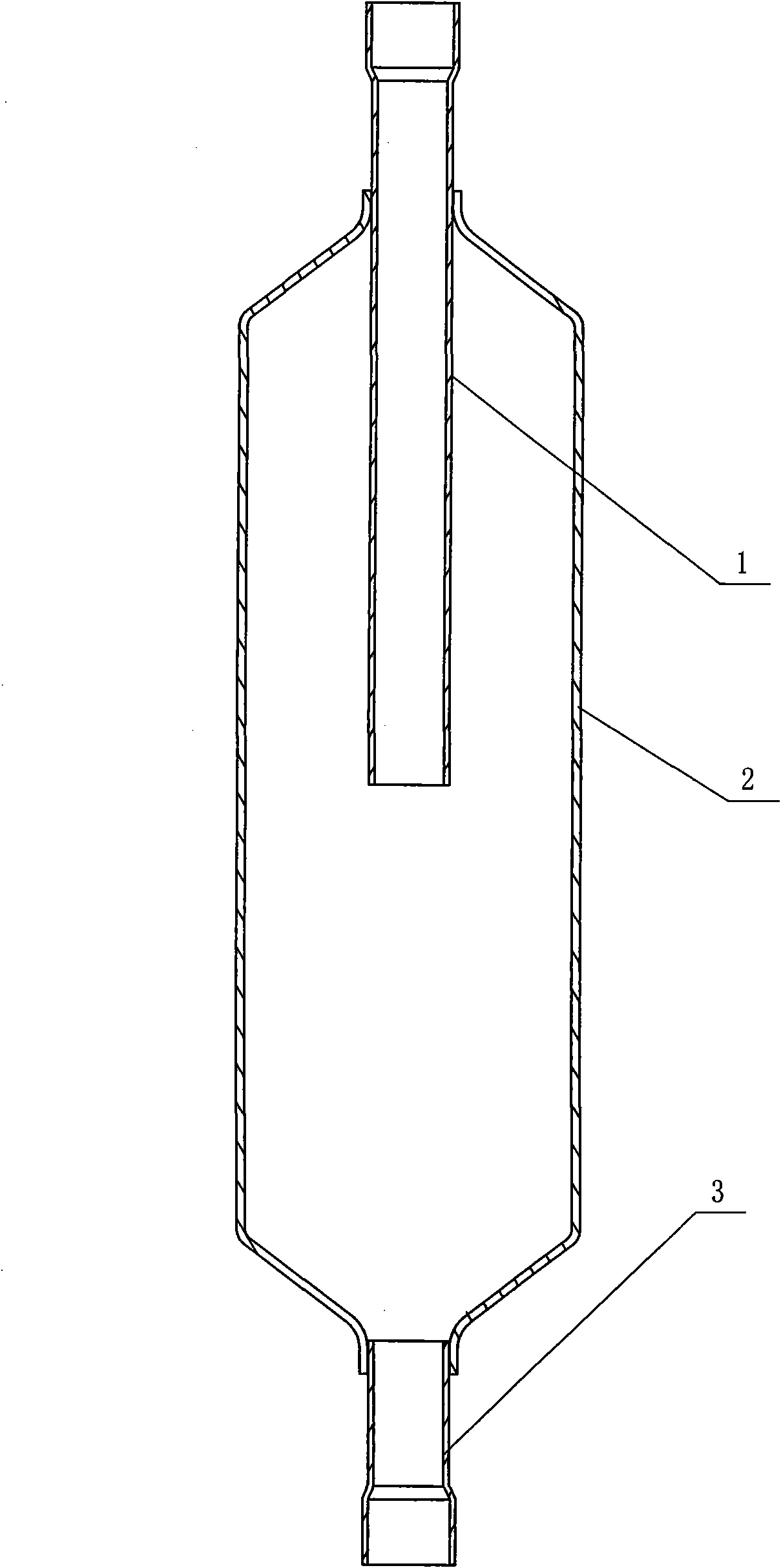

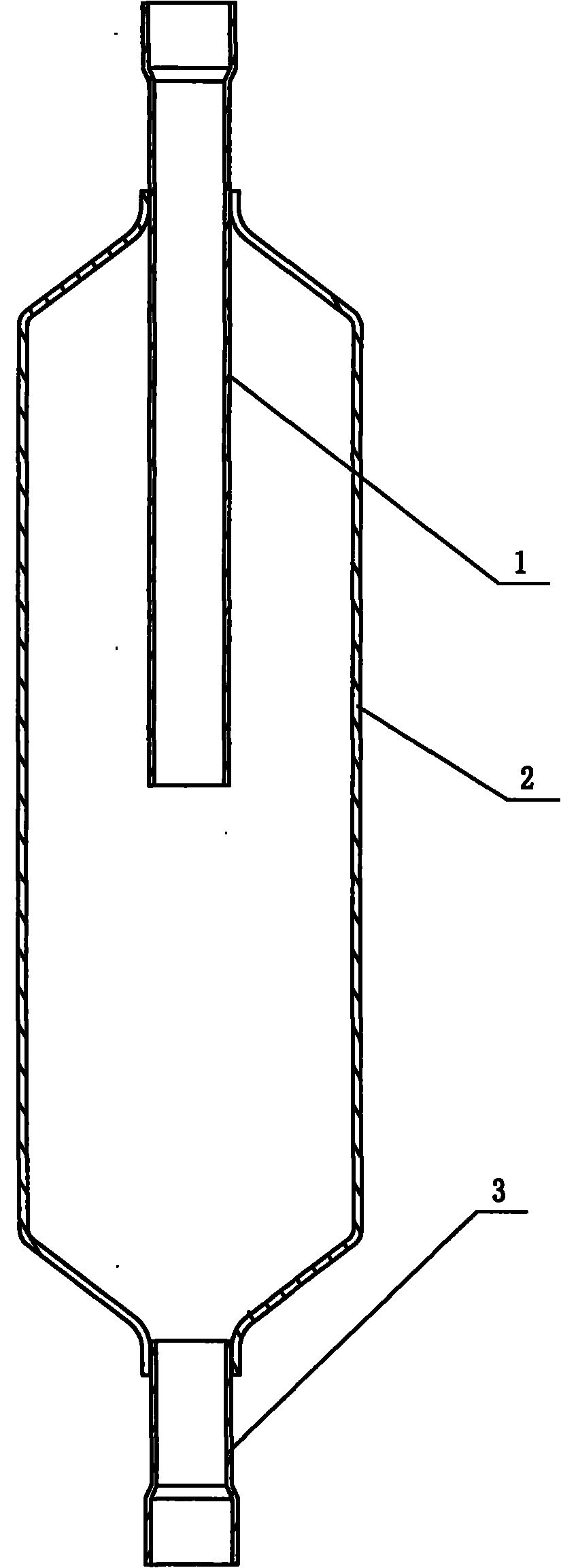

[0009] Such as figure 1 As shown, the stainless steel muffler of the present invention comprises a silencer pipe 2 and an air inlet pipe 3 and an air outlet pipe 1 welded to two ends of the silencer pipe 2. The diameter of the silencer pipe 2 is larger than the air inlet pipe 3 and the air outlet pipe 1, and the air outlet pipe 1 extends into the silencer pipe 2. Cavity, air intake pipe 3 and air outlet pipe 1 are copper pipes, and the material of silencer pipe 2 is stainless steel. The manufacturing process of the stainless steel silencer includes the following steps: the first step, the preparation of the silencer pipe, cutting off a stainless steel pipe of appropriate length, chamfering both ends of the stainless steel pipe, annealing the stainless steel pipe after chamfering, reducing the hardness of the steel pipe, and then using The spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com