Substrate cleaning apparatus, coating and developing apparatus having the same and substrate cleaning method

一种清洗装置、基板的技术,应用在清洁方法和用具、化学仪器和方法、摄影等方向,能够解决制造成本上升、涂覆显影装置占有面积变大、半导体集成电路制造成本上升等问题,达到节省空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

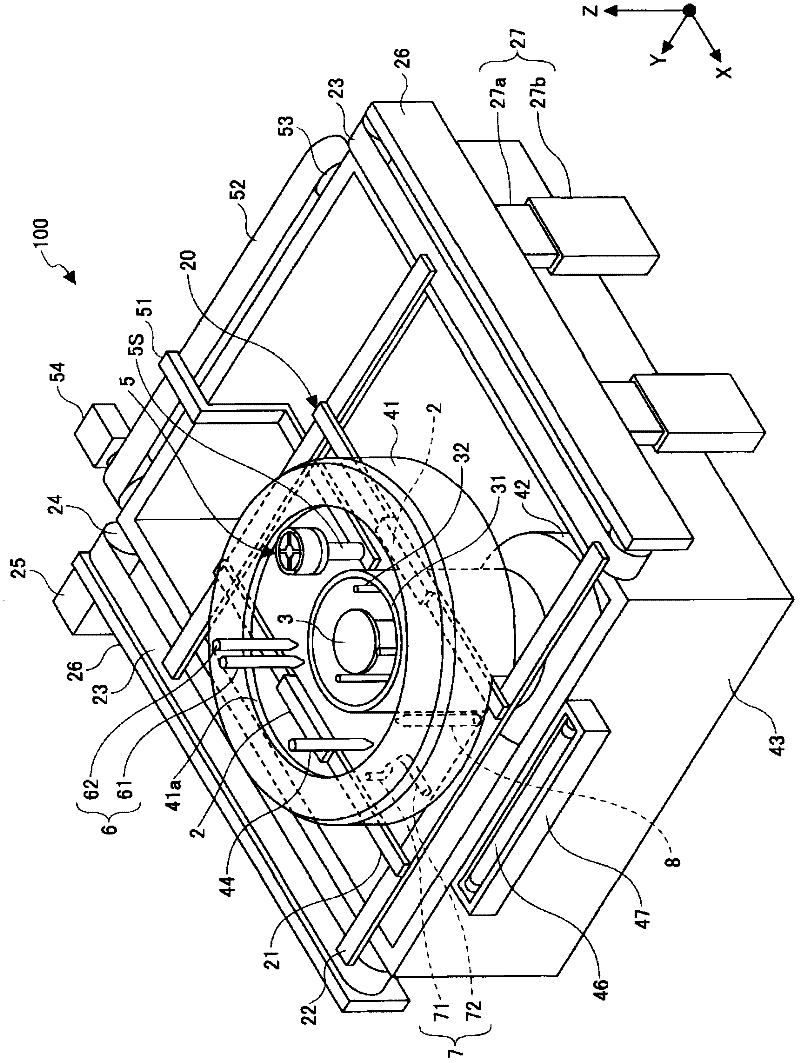

[0099] The chamfered portion of the experimental wafer was cleaned in the substrate cleaning apparatus 100 having the cleaning head 5 .

Embodiment 2

[0101] A brush made of bundled plastic fibers was used instead of a PVA sponge, and a cleaning nozzle 5 (described later) was installed in the substrate cleaning device 100 , and the chamfer of the experimental wafer was cleaned using the substrate cleaning device 100 department.

[0102] refer to Figure 13It can be seen that only about 42% of shavings were removed when the brush of the comparative example was used. It can be considered that such a removal rate is due to the fact that the brush of the comparative example does not have the central portion 5a and the ring portion 5b, and that the brush of the comparative example does not contact (or rub) the chamfer of the experimental wafer.

[0103] When the cleaning liquid was sprayed from the cleaning nozzle to the chamfered portion, about 47% of the shavings adhering to the chamfered portion were removed, and the removal rate was higher than that of the brush of the comparative example. However, since the cleaning using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com