DDMI (digital diagnostic monitoring interface) optical module transmitter circuit and optical power monitoring method for same

A technology of optical module and optical power, which is applied in the field of photoelectric communication, can solve the problems of reduced precision, inability to meet the accuracy requirements of the monitoring circuit at the sending end of the optical module, and unstable voltage, so as to achieve the effect of ensuring reliability, easy implementation, and simple sending circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

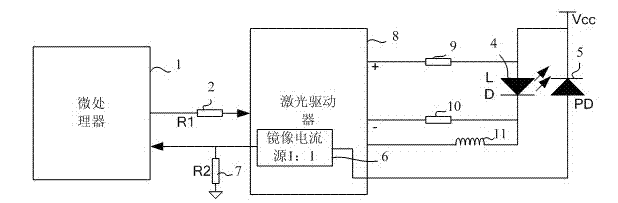

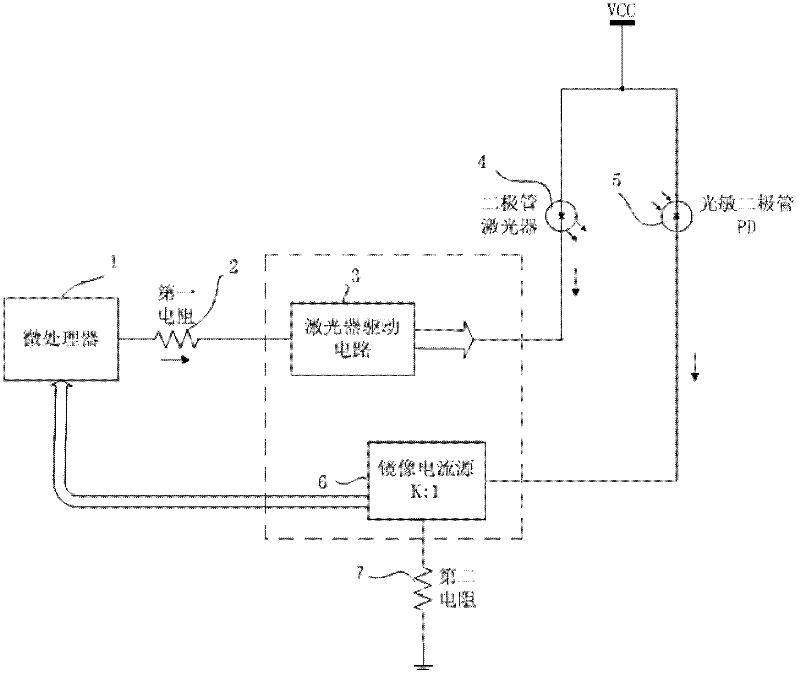

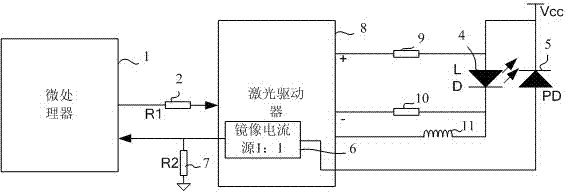

[0045] refer to figure 1 A DDMI optical module sending circuit is shown, the circuit includes a microprocessor 1, a first resistor 2, a laser drive circuit 3, a diode laser 4, a photosensitive diode 5, a mirror current source 6, and a second resistor 7, wherein the microprocessor The device 1 includes a digital-to-analog conversion (D / A) port and an analog-to-digital conversion (A / D) port. The digital-to-analog conversion port of the microprocessor 1 is connected to one end of the first resistor 2, and the other end of the first resistor 2 is connected to the laser drive circuit 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com