Method for making single-sided circuit board with flat wires arranged side by side

A circuit board, single-sided technology, applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, printed circuits, etc., can solve the problems of high cost, low efficiency, serious pollution, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A specific embodiment of a method for manufacturing a single-sided circuit board by juxtaposing flat wires according to the present invention will be described in more detail below.

[0047] However, those skilled in the art should understand that the following are only examples and descriptions of some preferred implementations, and other similar or equivalent implementations can also be used to implement the present invention.

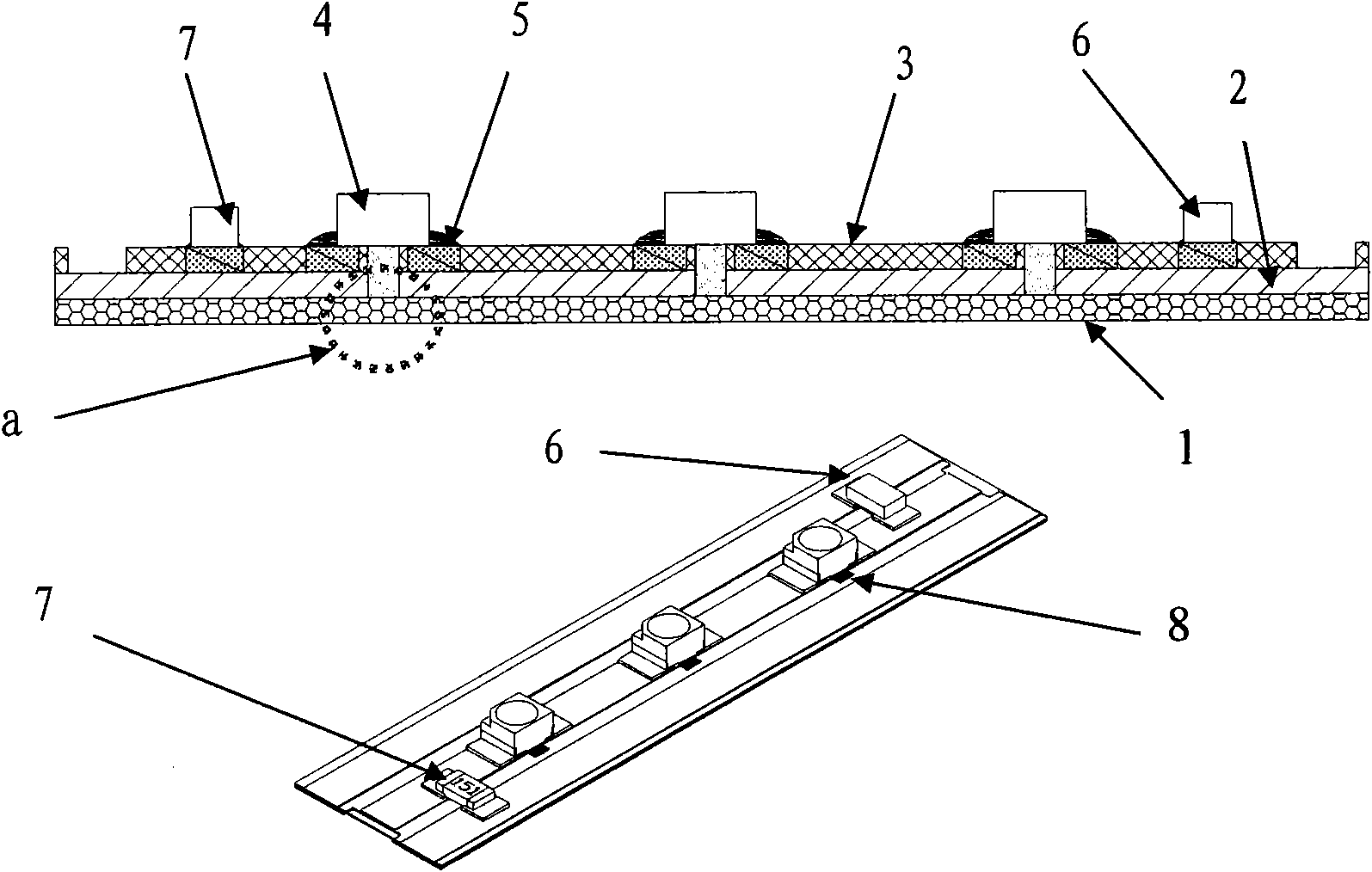

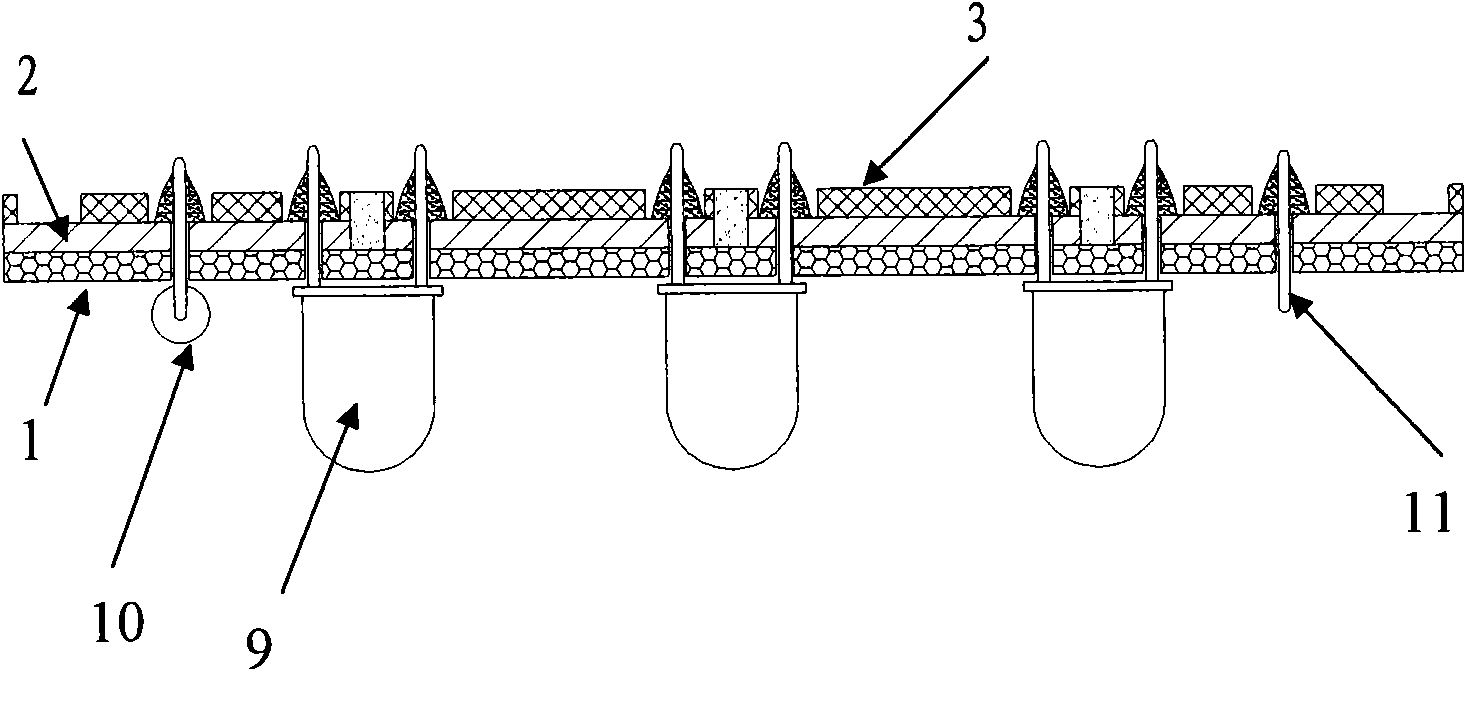

[0048] (1) Fabrication of rigid circuit board

[0049] 1. The production of flat wires is made by cutting copper foil into strips or rolling copper wires or flat wires of a certain width and thickness with a flat wire calender 2 (such as image 3 ).

[0050] 2. Fabrication of juxtaposition groove molds: process juxtaposition grooves 12 consistent with the line width by using a mirror surface stainless steel plate by etching or mechanical processing (such as Figure 4 shown), the depth of the groove 12 is shallower than the thickness of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com