Chemical mechanical planarization using nanodiamond

A chemical-mechanical, diamond-based technology used in inorganic chemistry, other chemical processes, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

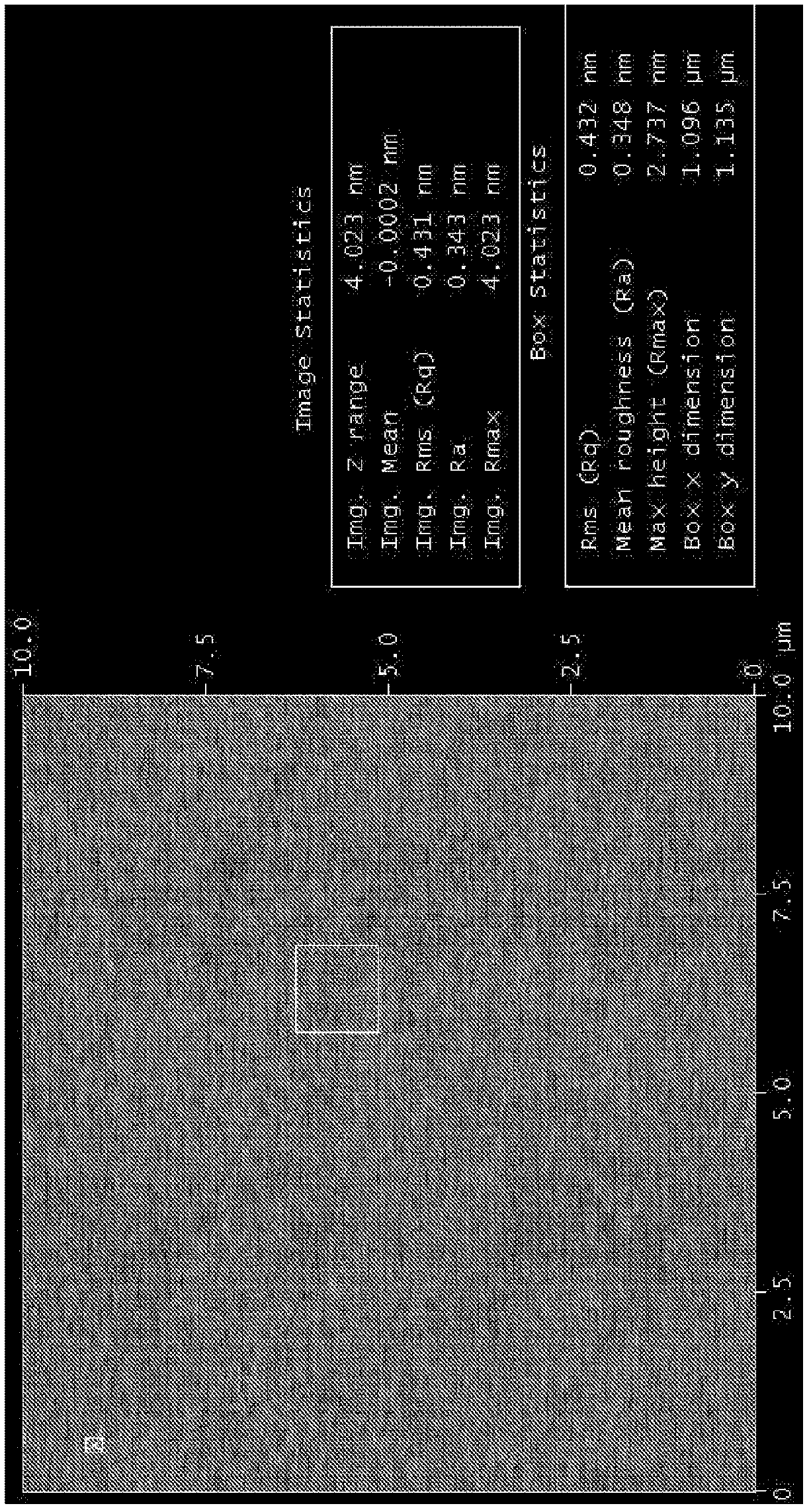

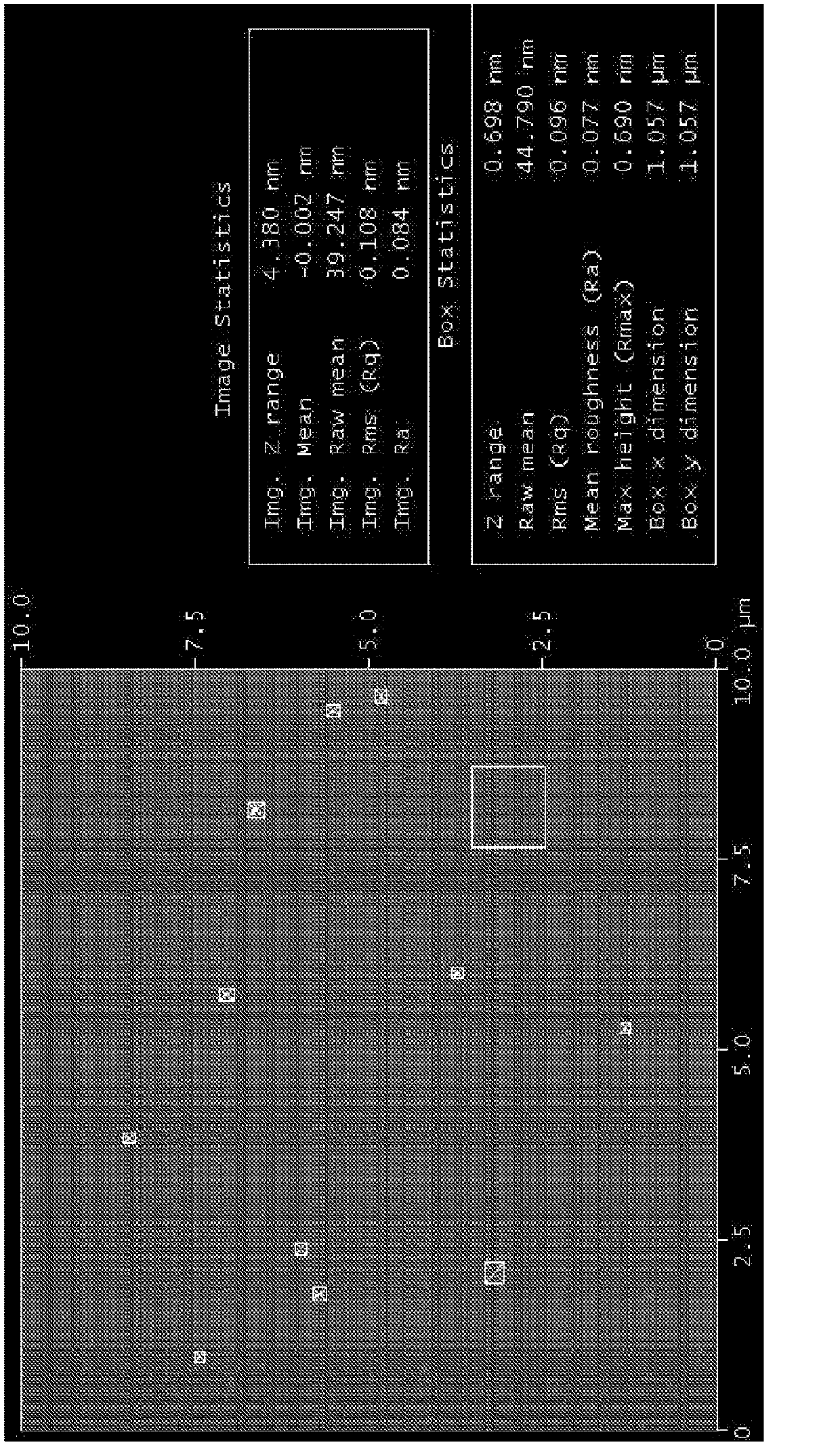

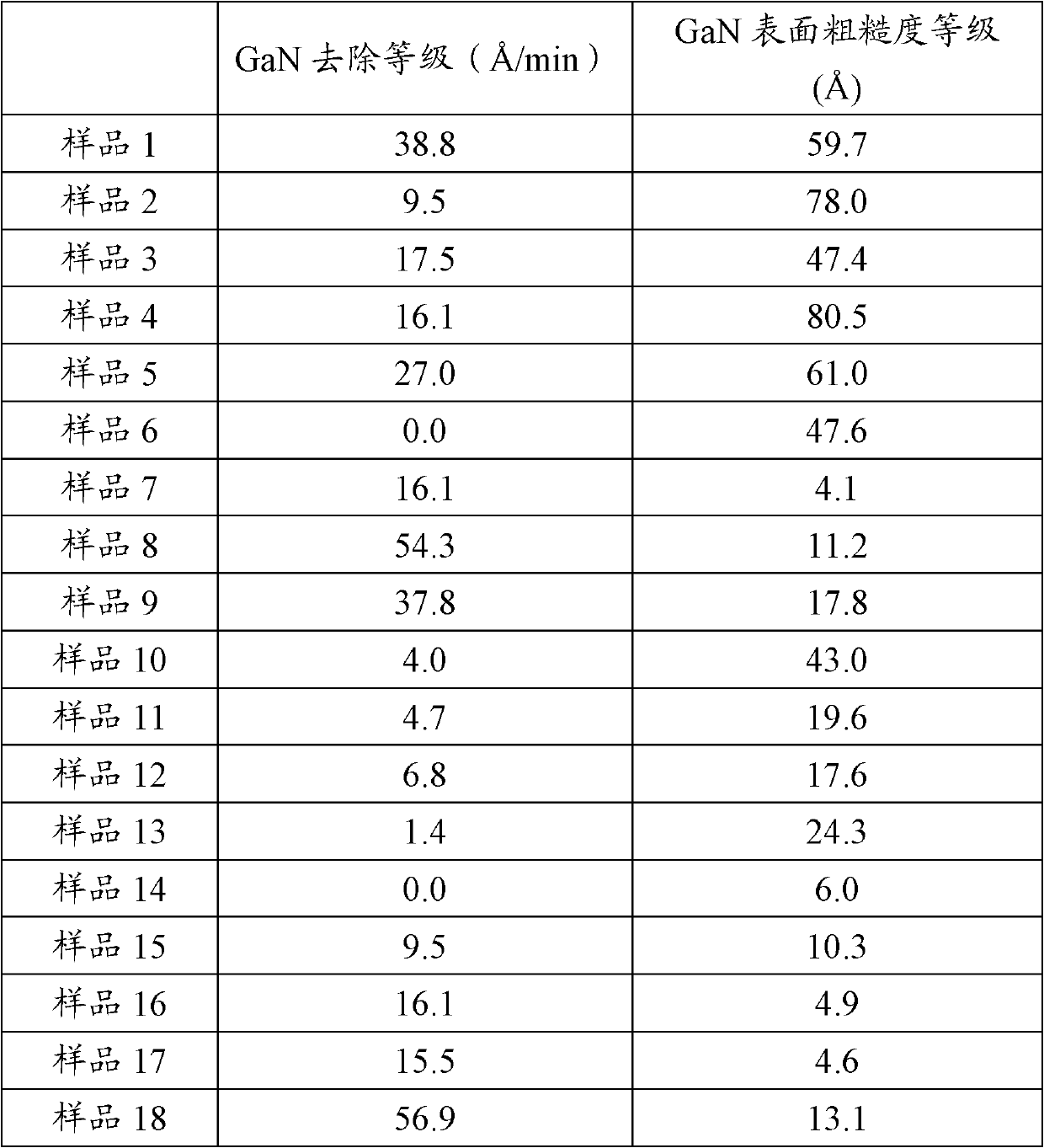

[0026] Slurry samples were prepared and tested to determine material removal and surface roughness. The following standardized procedures were used to measure the GaN surface roughness level and GaN removal level. A 2 inch bulk GaN wafer was polished for 60 minutes with an IC-1000 pad from Eminess Technologies using a Strasbaugh 6BK 16 inch single side polisher. The polishing was performed at 50 rpm and a pressure of 1.4 psi. The slurry was applied at a drop rate of 22 mL / min. The weight of the GaN wafer was measured before and after polishing. Pass based on poor quality and GaN density of 6.1g / cm 3 Instead, the volume of GaN removed is calculated to determine the GaN removal level. The volume of GaN removed is assumed to be a cylinder with a radius of 1 inch. The GaN removal level was determined by taking the height of the cylinder and dividing by the time (60 minutes). GaN surface roughness ratings were determined by averaging Ra over five different irregularities usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com