Shielding braid termination for shielded electrical connector

A technology for electrical connection and shielded cables, which is applied in the direction of conductive connections, vehicle connectors, and parts of connection devices. It can solve problems such as high resistance, insufficient vibration and temperature changes, difficult and expensive assembly, and achieve reduction Small production cost, reduced electrochemical corrosion potential, and the effect of absorbing assembly tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

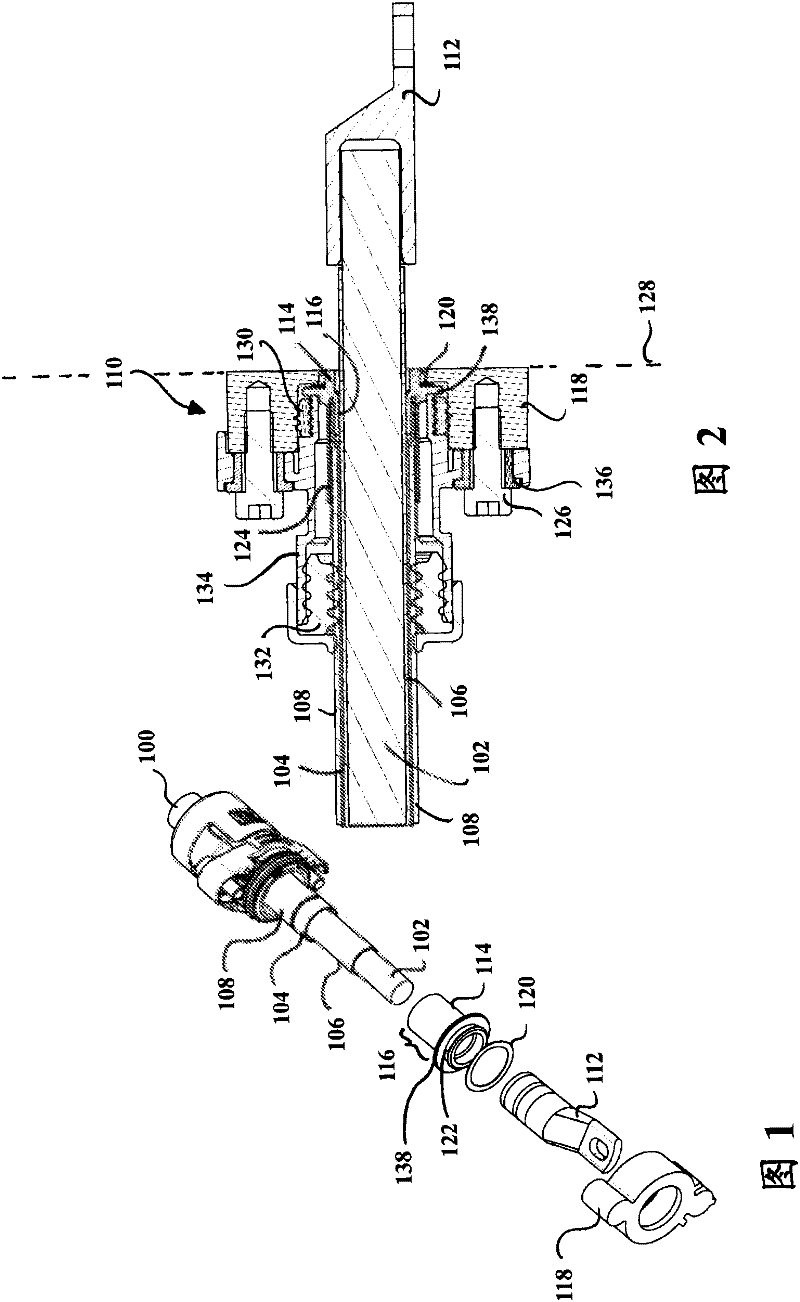

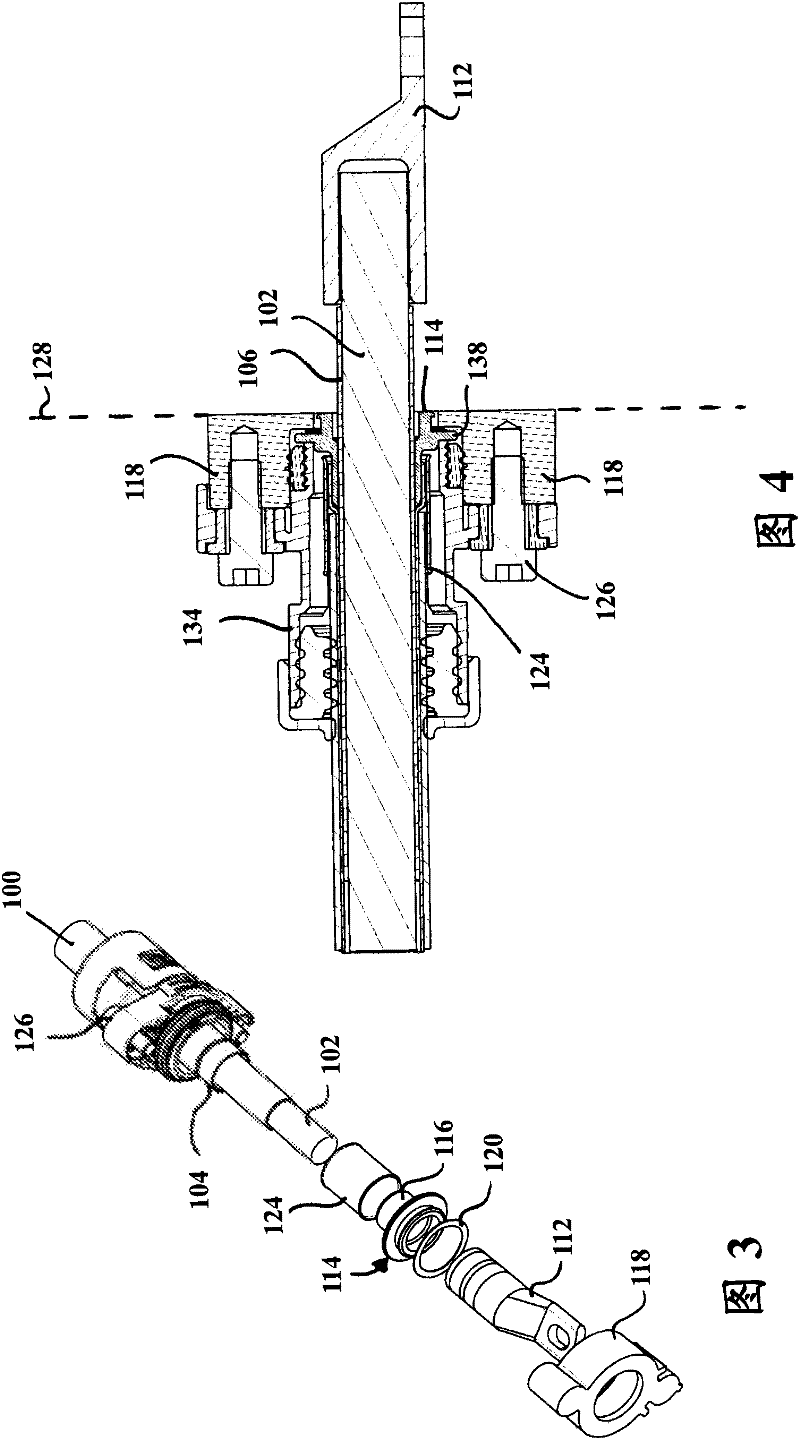

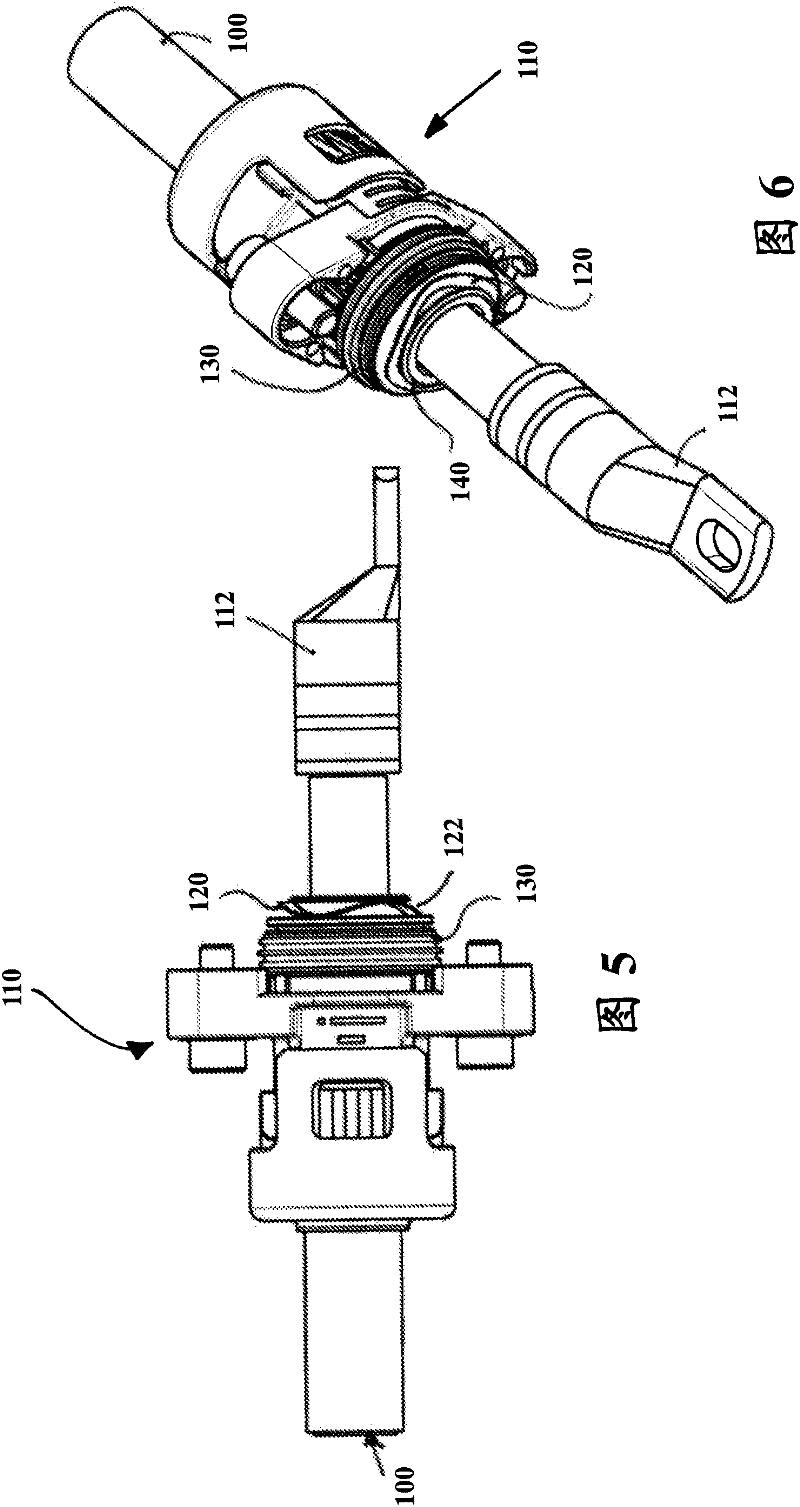

[0035] figure 1A partially exploded view of FIG. 2 shows a connector for a shielded cable 100 according to a first embodiment of the present invention. The shielded electrical cable 100 includes a center conductor 102 separated from a surrounding shield braid 104 by an insulating layer 106 . The cable jacket 108 insulating the shielded cable 100 is removed, exposing the shield braid for contact by the shield termination structure 110 of the present invention.

[0036] The center conductor is electrically contacted by terminal 112 . However, the particular shape of the terminal 112 is not relevant to the shield termination structure of the present invention.

[0037] According to the invention, a shielding body 114 is provided, which is formed as a convoluted piece, for example from aluminum. In the connection region 116, the shield body 114 can be brought into contact with the shield braid 104 to connect the shield body 114 to the figure 1 The interface 118 is shown as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com