End actuator of dry land plug tray transplanter

An end effector and dry land technology, applied in the fields of transplanting machinery, application, agriculture, etc., can solve the problems of poor flexibility, bulky, complex mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

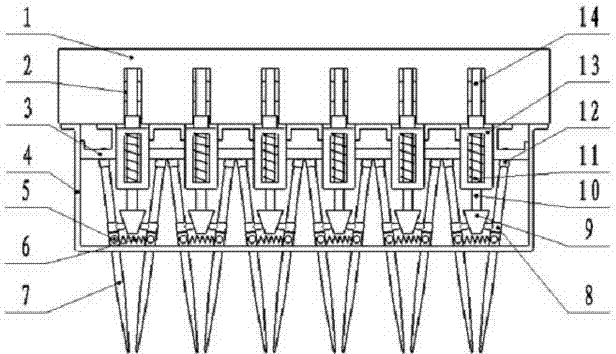

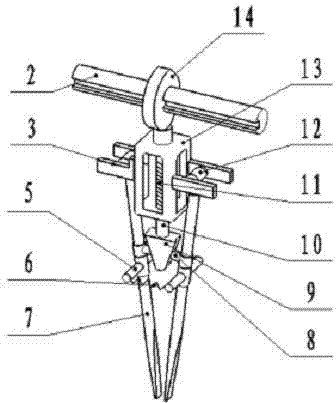

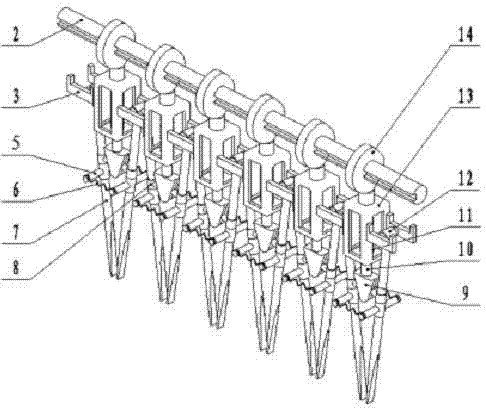

[0023] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0024] like figure 1 As shown, the camshaft support 1 among the present invention is connected on the mechanical arm of the transplanting machine, and the camshaft 2 is installed in the camshaft support 1, and a group of cams 14 are housed on the camshaft 2, and the cam 14 and the camshaft 2 are connected by keys, Through the rotational drive of the camshaft 2, each cam 14 is driven to rotate together. The bottom end of the camshaft support 1 has a small hole 16, where the push rod 10 which is always in contact with the cam 14 is installed. Push rod 10 thickness junction, the other end is supported on the push rod bracket 13, so stage clip 11 is in compressed state all the time, cam 14 and push rod 10 can contact all the time, thereby the rotation of cam 14 turns into the up and down movement of push rod 10.

[0025] The wedge-shaped block 9 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com