Deep-curvature glass cleaning machine

A glass cleaning, deep curvature technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of high production efficiency, high cleanliness, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

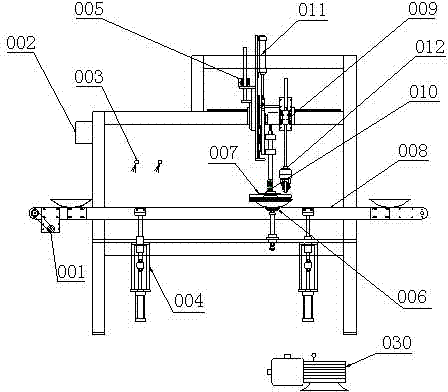

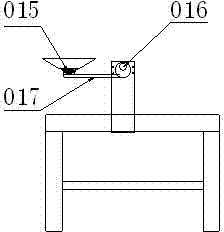

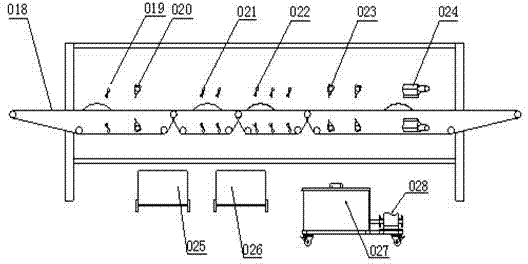

[0014] Embodiment: The structure of the deep curvature glass cleaning machine of the present invention is shown in the accompanying drawings, including a frame, a front brushing part and a rear washing and drying part, and its main features are the transmission mechanism, the front brushing part and the rear washing The drying part is equipped with glass detection sensors; the front brushing part includes a high-pressure cleaning table and a hanging cleaning brush rotary table (if attached figure 1 ); the subsequent washing and drying part includes a glass turning unit (as attached figure 2 ), decontamination rinse unit, re-rinse unit, final rinse and drying unit (if attached image 3 ); the upper part of the high-pressure cleaning table is provided with an inclined nozzle 003 whose spray range covers the entire width of the glass, and the distance between the inclined nozzle 003 connected to the clean water pump 030 and the glass is adjustable; the suspended cleaning brush r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com