Composite punch die for workpiece with multiple long slotted holes

A compound punching die and long slot technology, which is applied in the direction of perforating tools, metal processing, manufacturing tools, etc., can solve the problems that the workpiece waste cannot be discharged from the top to the bottom, punching needles with multiple long slot holes on the aluminum substrate, and low work efficiency. Achieve the effects of increased energy consumption, improved structural strength, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further description will be given below in conjunction with the accompanying drawings of the embodiments.

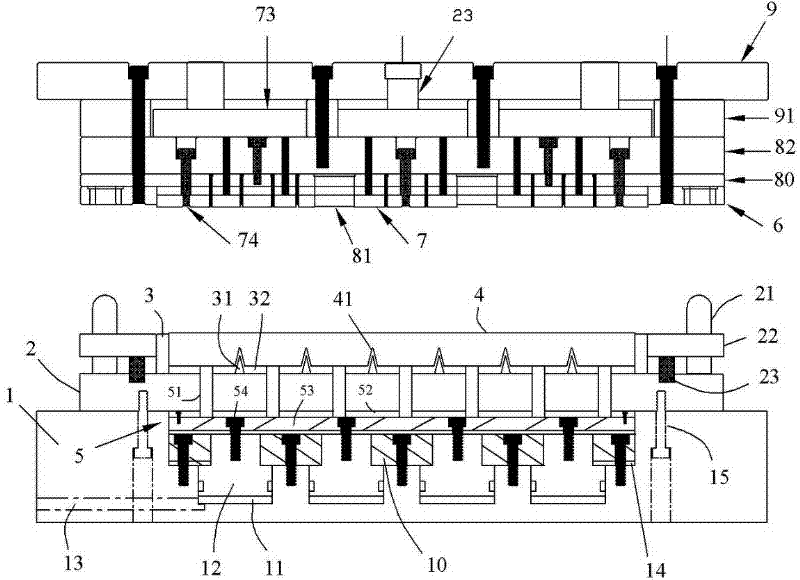

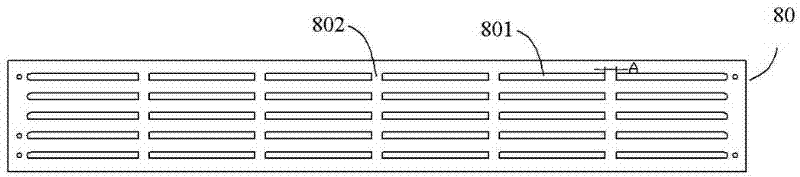

[0026] refer to Figure 1-9 , The multi-slotted workpiece compound punching die includes an upper die part and a lower die part. The main structure of the upper mold part is basically the same as that of the traditional upper mold. The upper mold part mainly includes a die plate 9, a female mold 6 installed on the die plate 9, a punch plate 80 and a needle presser plate 82, and a discharge plate 7 positioned in the die opening of the female mold 6 and the like.

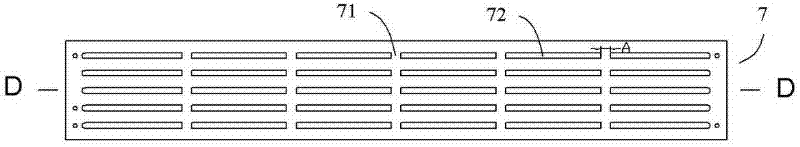

[0027] The discharge plate 7 in the upper mold part is provided with a plurality of strip-shaped via holes 72, and a number of connecting blocks 71 are reserved at the upper opening of each strip-shaped via hole, and the connecting blocks divide the upper opening of the strip-shaped via hole into multiple long mouths; figure 1 The unloading plate 73 and the unloading plate screw 74 etc. are the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com