Novel process for producing mortar concrete waterproofing agent

A mortar concrete and production process technology, applied in the field of new mortar concrete waterproofing agent production process, can solve the problems of easy aging, high cost, short service life, etc., to improve impermeability and crack resistance, prolong waterproof service life, and enhance use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

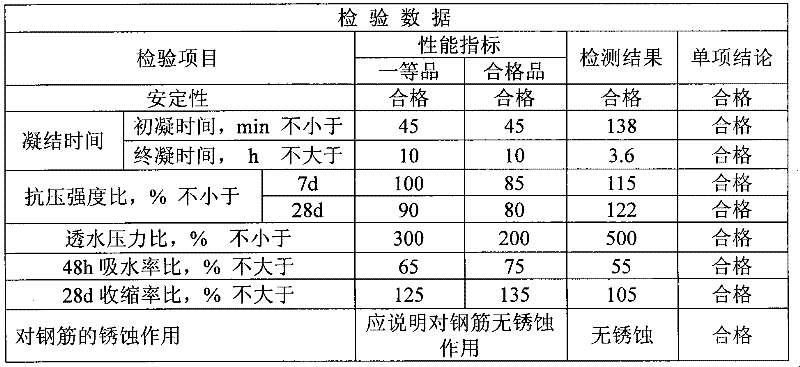

Image

Examples

specific Embodiment approach 1

[0031] Its specific implementation mode one is:

[0032] 1. Remove impurities from raw materials by filtering;

[0033] 2. Add octadecanoic acid and silane to water respectively for dilution according to the weight ratio of 15%, put the diluted solution into the reactor and heat to 70°C for 30 minutes;

[0034] 3. Add sodium rosinate into the reactor according to 4% of the weight of octadecanoic acid and silane, heat and stir at 70°C for 30 minutes, and the stirring speed should not be lower than 300 rpm;

[0035] 4. Add sodium hydroxide to the reactor according to 10% of the weight of octadecanoic acid and silane, heat and stir at 70°C for 30 minutes, and the stirring speed should not be lower than 300 rpm;

[0036] 5. Add triethanolamine into the reactor according to 0.9% of the weight of octadecanoic acid and silane, cool down to 50°C, stir for 30 minutes, then heat to 80°C, stir for 40 minutes, and cool naturally to form the waterproofing agent.

specific Embodiment approach 2

[0037] Its specific implementation mode two is:

[0038] 1. Remove impurities from raw materials by filtering;

[0039] 2. Add octadecanoic acid and silane to water respectively for dilution according to the weight ratio of 20%, put the diluted solution into the reactor and heat to 80°C for 30 minutes;

[0040] 3. Add sodium rosinate into the reactor according to 3% of the weight of octadecanoic acid and silane, heat and stir at 80°C for 30 minutes, and the stirring speed should not be lower than 300 rpm;

[0041] 4. Add sodium hydroxide to the reactor according to 15% of the weight of octadecanoic acid and silane, heat and stir at 80°C for 30 minutes, and the stirring speed should not be lower than 300 rpm;

[0042] 5. Add triethanolamine into the reactor according to 0.7% of the weight of octadecanoic acid and silane, cool down to 60°C, stir for 30 minutes, then heat to 90°C, stir for 40 minutes, and cool naturally to form the waterproofing agent.

specific Embodiment approach 3

[0043] Its specific implementation mode three is:

[0044] 1. Remove impurities from raw materials by filtering;

[0045] 2. Add octadecanoic acid and silane to water respectively for dilution according to the weight ratio of 16%, put the diluted solution into the reactor and heat to 75°C for 30 minutes;

[0046] 3. Add sodium rosinate into the reactor according to 3.5% of the weight of octadecanoic acid and silane, heat and stir at 75°C for 30 minutes, and the stirring speed should not be lower than 300 rpm;

[0047] 4. Add sodium hydroxide to the reactor according to 12.5% of the weight of octadecanoic acid and silane, heat and stir at 75°C for 30 minutes, and the stirring speed should not be lower than 300 rpm;

[0048] 5. Add triethanolamine into the reactor according to 0.8% of the weight of octadecanoic acid and silane, cool down to 55°C, stir for 30 minutes, then heat to 85°C, stir for 40 minutes, and cool naturally to form the waterproofing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com